Output Devices

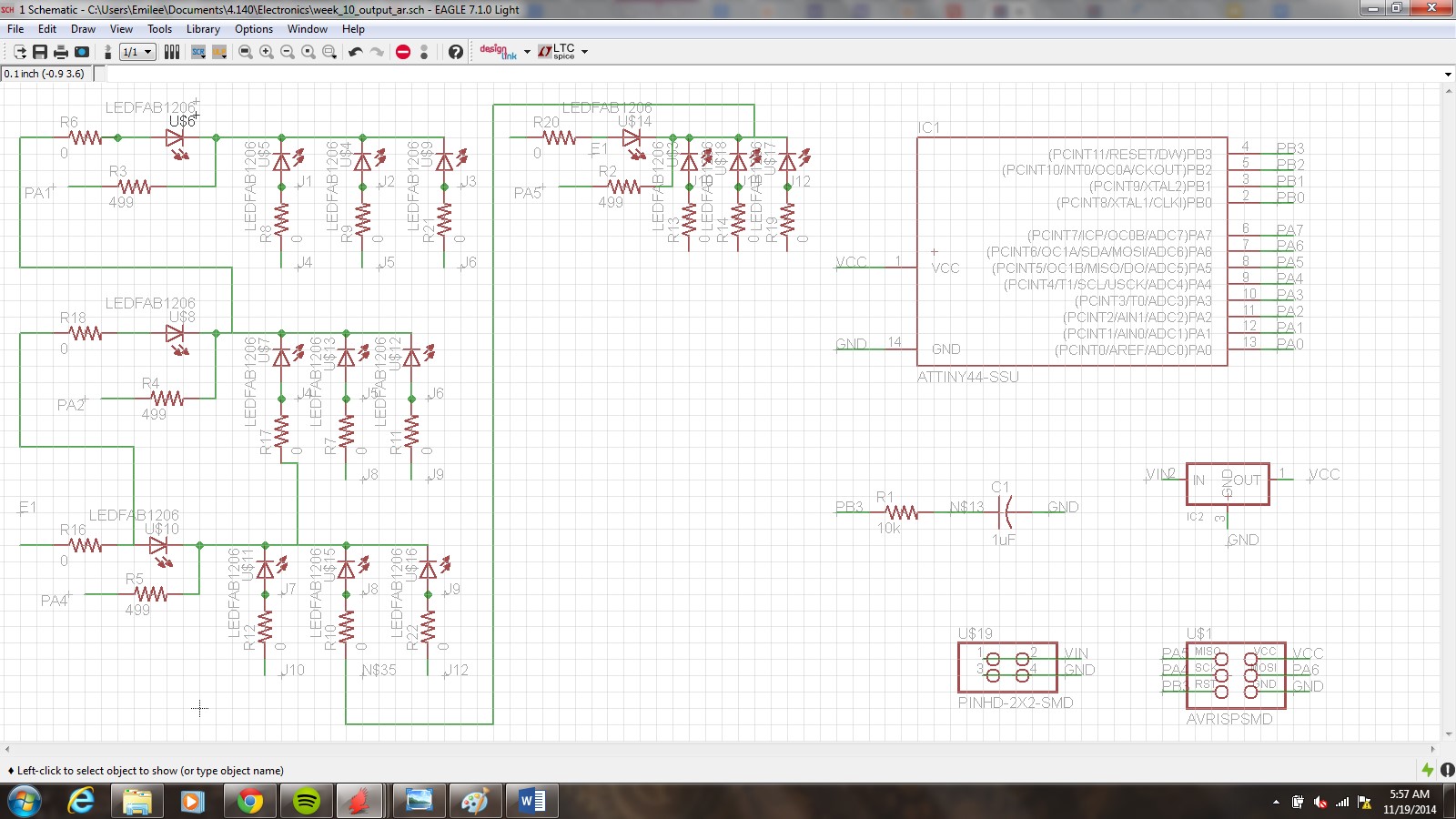

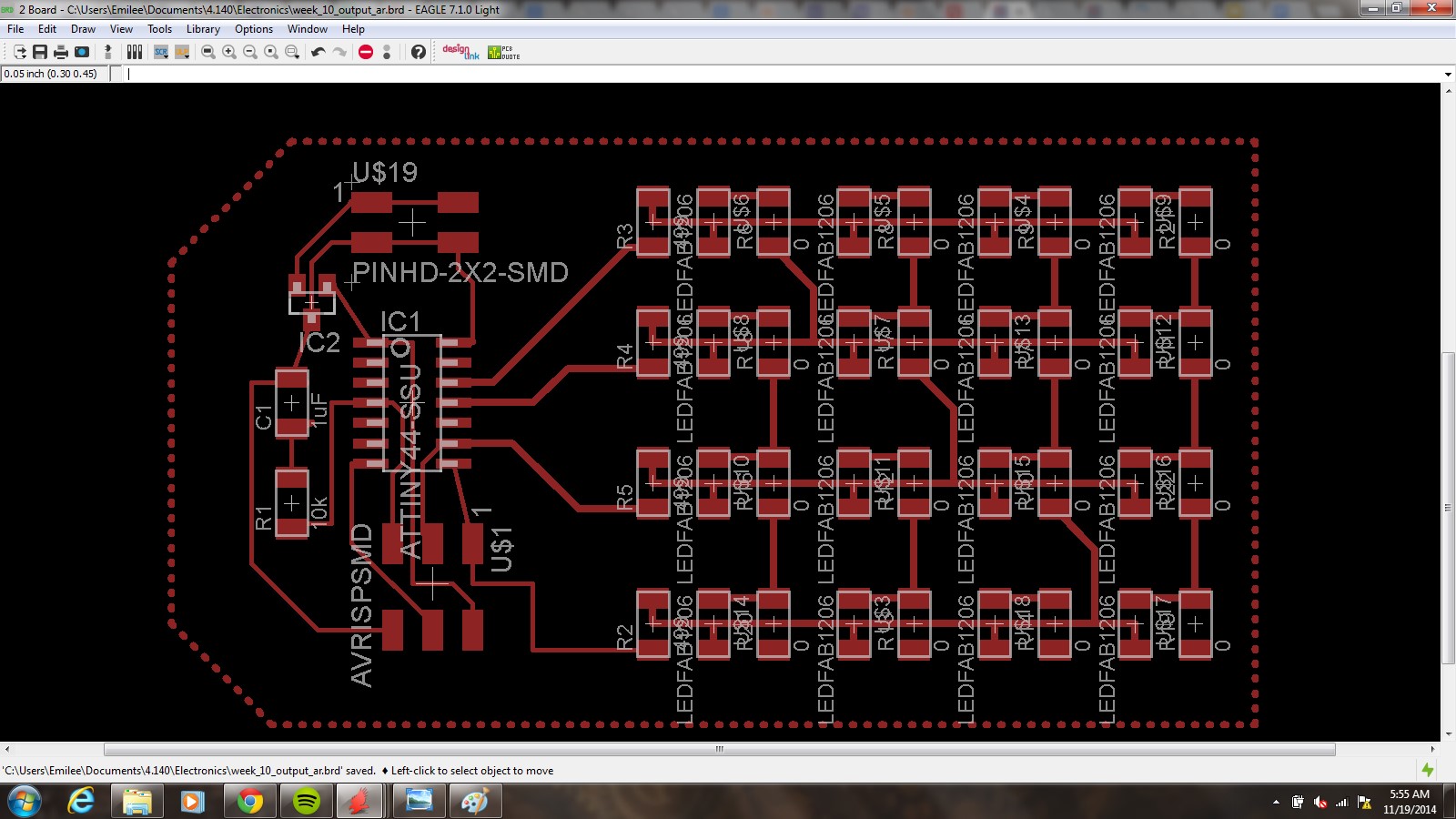

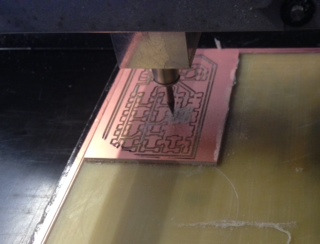

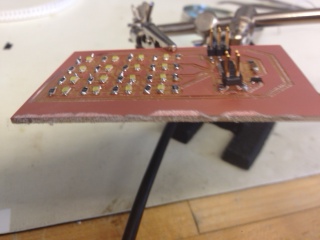

So....output devices. This week we had to design our own board and make it do something. I didn't venture particularly far out this week in terms of creativity, but it was a very valuable week for me because I have decided to update my final project, which I will talk about again shortly. Anyway, so I chose to modify Neil's board and simply reduce the number of LEDs to make a square setup. My objective was to play with Eagle a bit and also create something that I can try out different codes over the next week or so that directly relates to my plan for my final project.

Final project update! I will include some sketches as soon as I have them and start posting the final project link over the next week with information about my BOM and manufacturing process. I decided to scratch the chess board idea finally for a few reasons. One of the bigger ones is that someone's already done exactly what I wanted to do not too long ago in this class (which I did not realize at the time) and I also felt like it was a bit out of my depth and too specific to some programming specifics that I didn't particularly care for. Now what I'm interested in doing is creating a speaker set up for my room. I'm going to build two speakers of hopefully reasonable quality, which will be mostly an assembly project. The fun addition that I want to add to this set up is a (large) audio spectrum analyzer that I can mount on my wall over my external monitor and where I plan to place my speakers. This is why I was interested in trying out the LEDs this week. I think it's going to be a tedious and involved process on the manufacturing end to build the set up (because really there's no fun in just buying the display right?) but I'm actually genuinely a lot more excited for this idea than my first one and I think it's something that I would get a lot of functional use out of, as well as something that I've never even considered trying prior to taking this class.