Week 6 - Molding and Casting

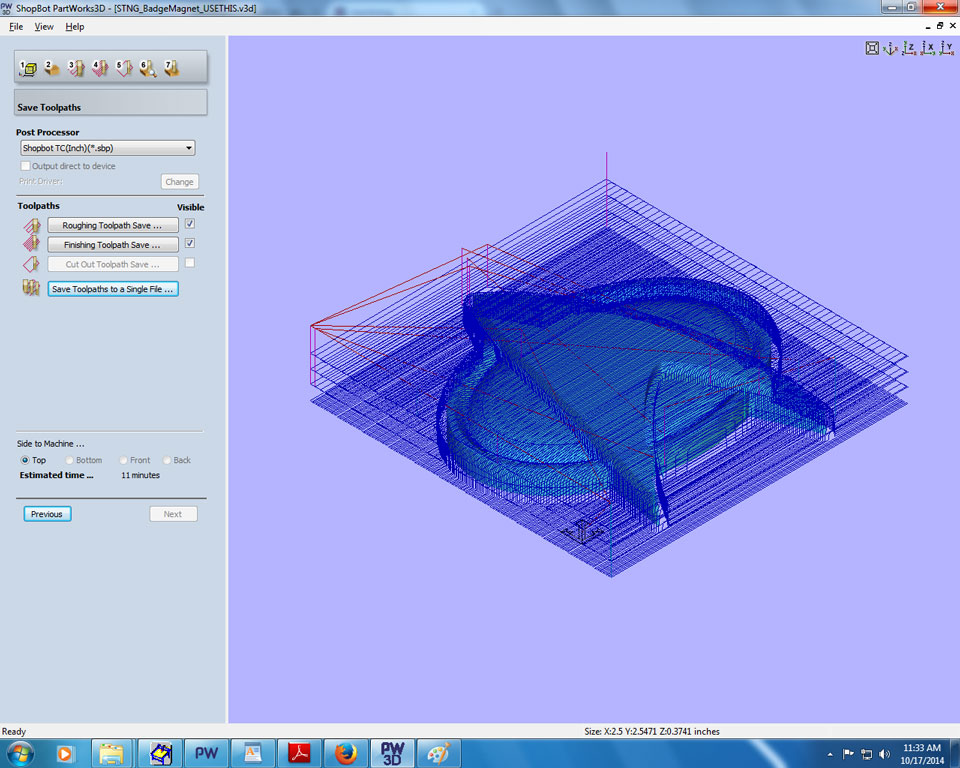

Making the Star Trek CommunicatorI had little time this week to do something crazy (Member's week), so I decided to make something simple and nice - the Star Trek Communicator (TNG version). The interesting part was creating a 3d toolpath for the first time. Surprisingly, this was even easier than the 2d version, as you can see below.

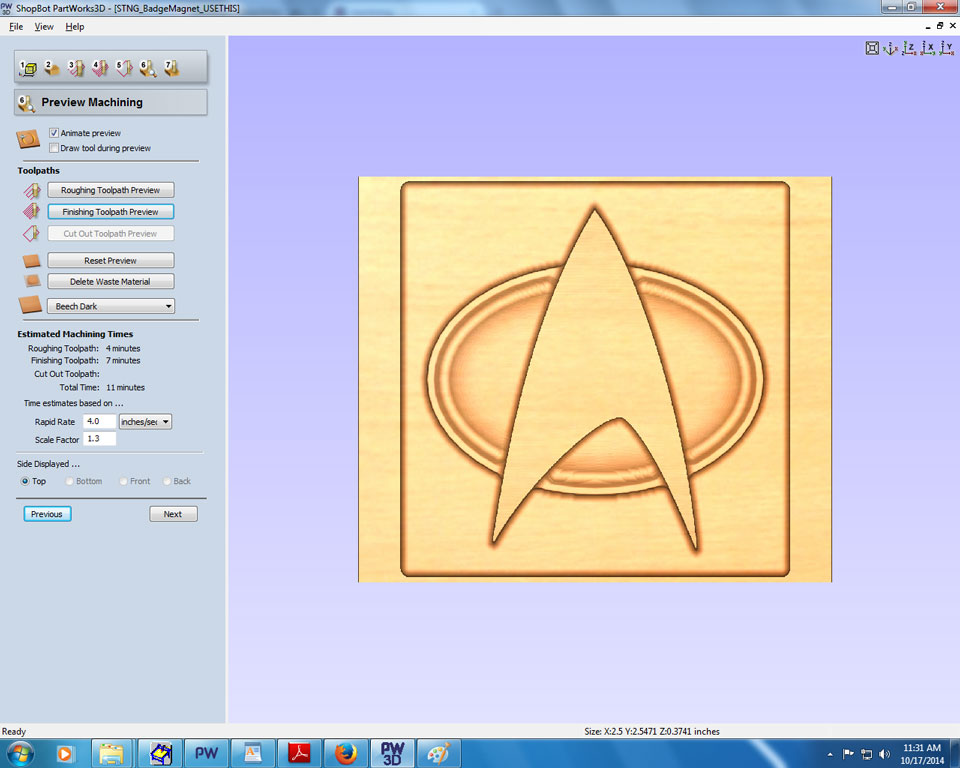

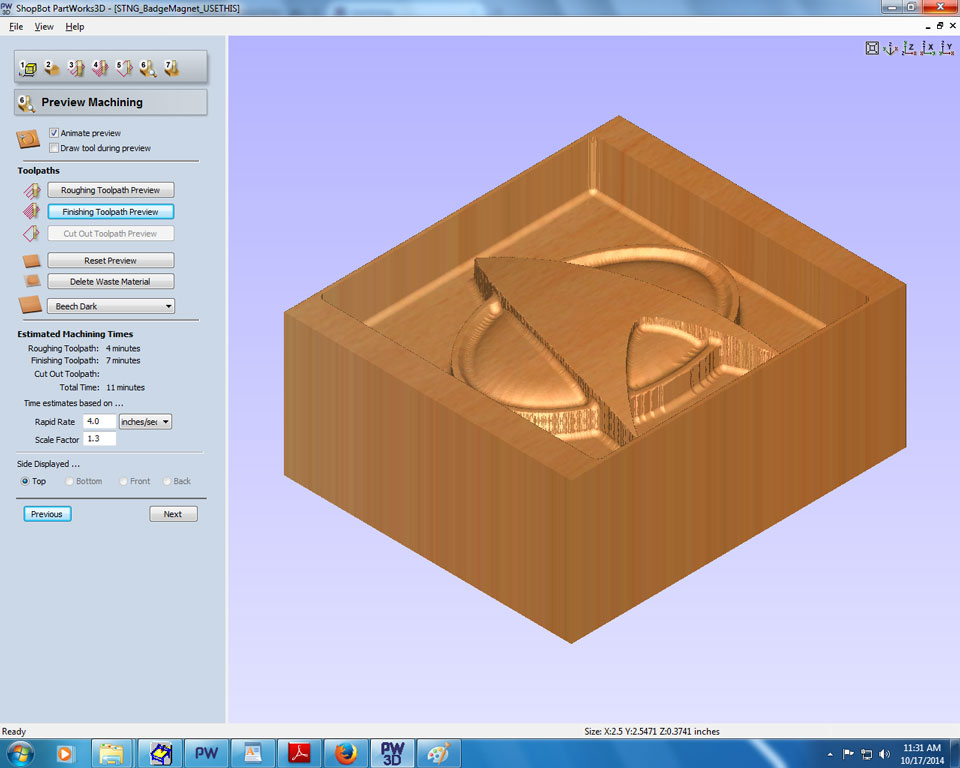

The toolpath can then be viewed as a preview. This is super helpful, since that way I could see in the beginning that my model wasn't deep enough. I corrected the depth settings and got the following result:

Milling was surprisingly easy after 'make something big' week. I attached the wax piece on a small sheet of OSB. The OSB sheet was screwed into the sacrificial layer, and the wax was glued to the OSB surface. After less than 15 minutes of milling, I got a nice result:

Next step was mixing the Oomoo to get a rubber mold:

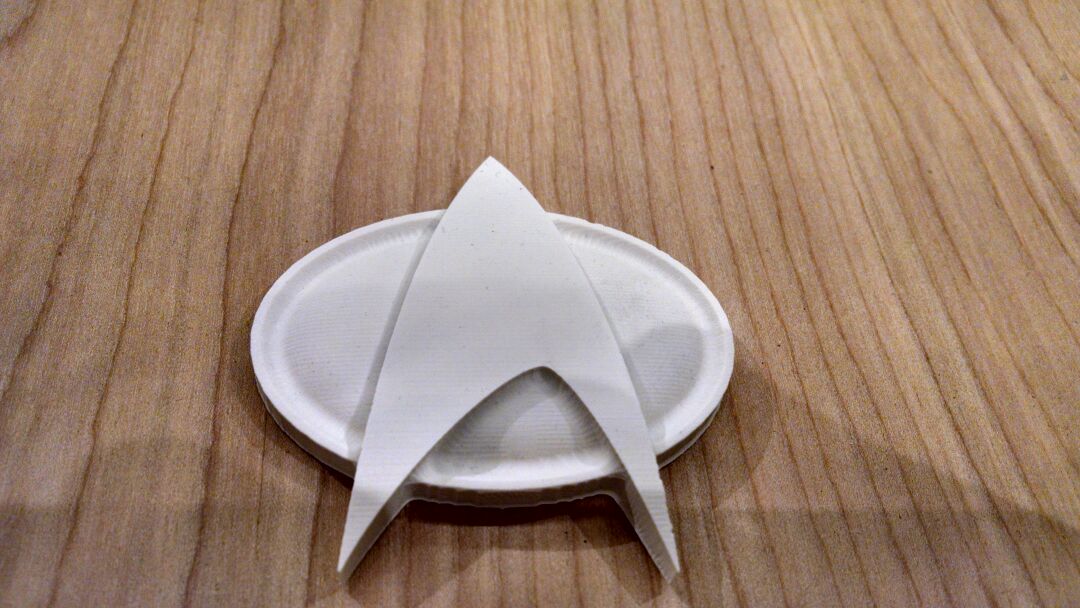

Then casting. I used 1 (water) : 4 (drystone), which gave really nice results. I mixed it for around 3 minutes before slowly pouring it in. It's important to note that if the mold permits - you should leave a very tiny gap at the end so the cast doesn't overflow. Even if it doesn't look perfectly even on its liquid form, it dries up very nicely and even.

Here's the end result!