Making something BIG

Furnishing my apartment...

Yes, I will furnish my apartment while doing a school's project, why not?

We need a coffee table for our living room. So I embarked on a search for inspiration. I paid a visit to Restoration Hardware. I saw a table that had a beautiful design. I did not get to that level this time (actually far from it, as you can see), but will eventually get there for sure.

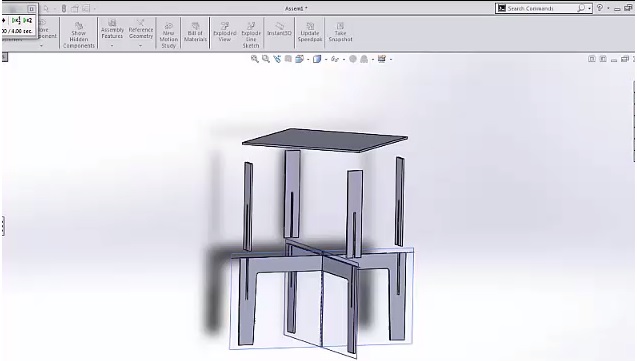

Another important step in my workflow is to see what has been done in the past and what tutorials are available in different sources online. I had to look two different types of tutorials, one for learning how to make a table like this one here. and another type that explained more about how to model furniture and assemblies in Solidworks. For the latter I have been relying on youtube searches and lynda.mit.edu After a few hours of searching examples and making up my mind, I decided to build a coffee table

The tutorials I found on designing furniture helped to have a good idea of what kind of assemblies I should be aiming for. For giving dimensions to my coffee table I just measured similar furniture at home to get a good sense of this. Off I go to model the table in Solidworks. It took me a bit of time but eventually got there. I used the assembly feature in Solidworks to make sure the dimensions of different pieces made sense

Off to MILLING

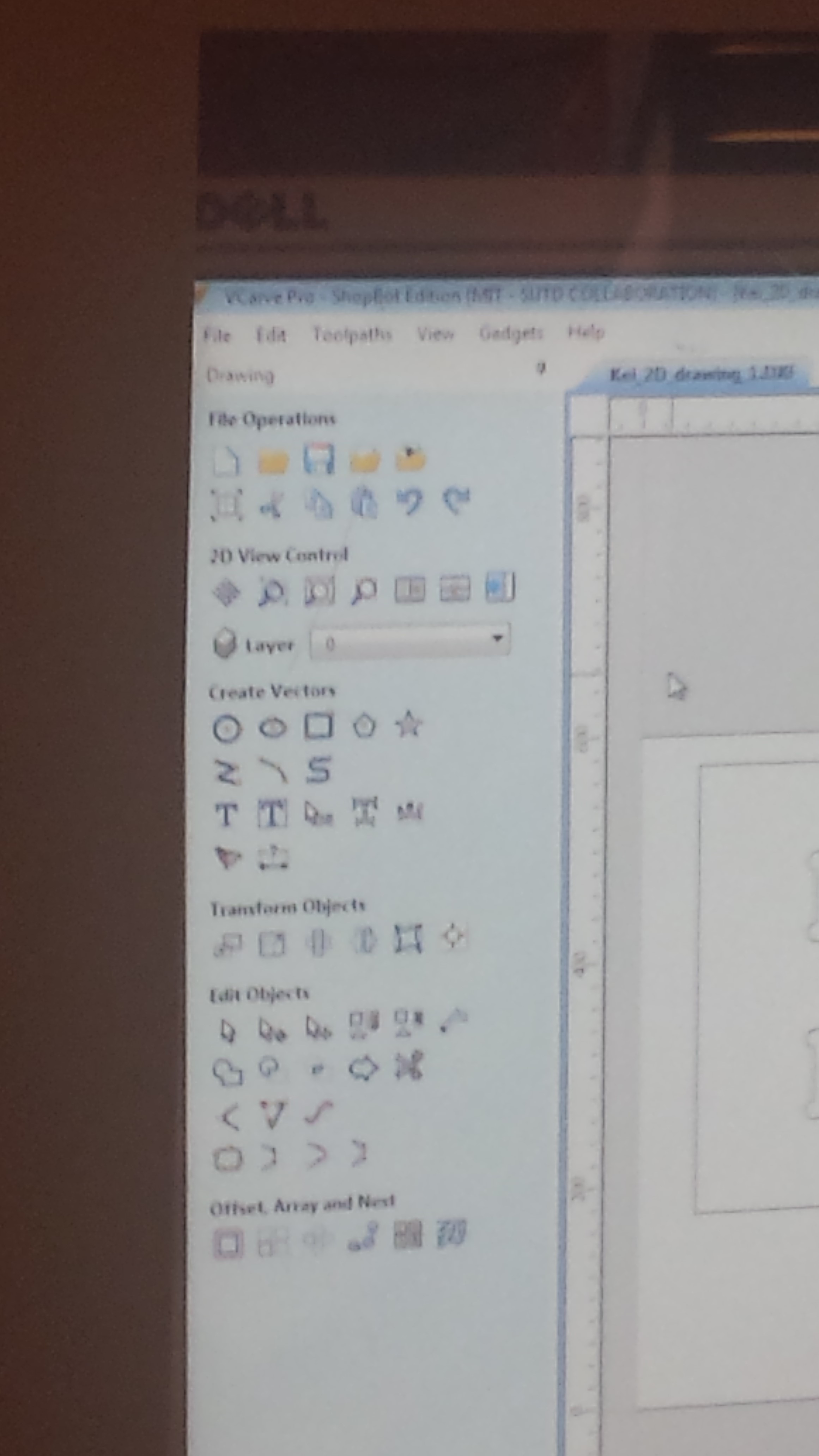

The machine at the IDC lab at MIT is a full size Shopbot (dimensions 96"x 48"x 6") here. The plywood sheet I loaded onto the Shopbot had a .45 thickness. So I set up the cut depth at .47. Worked just fine.

And finally the assembly.