I tried using the modela first but it was not my week with this machine. From what I heard from other section mates there was a miss adjustment in the machine. So time for looking for an alternative. The shopbot it is.

In a nutshell this week's ride:

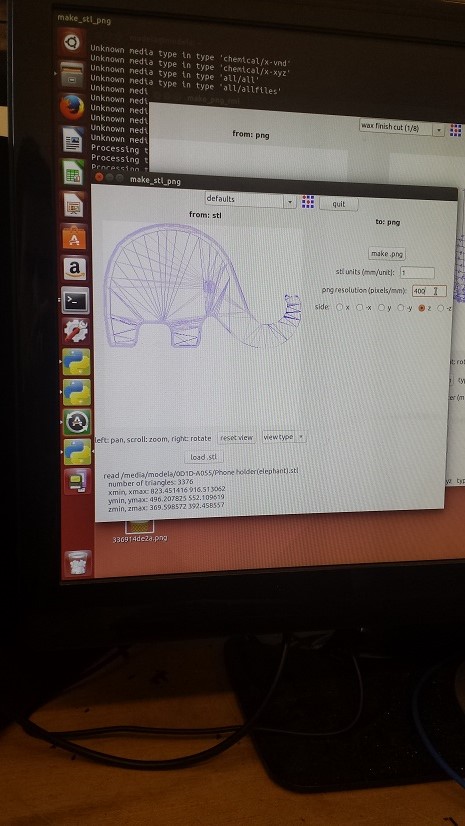

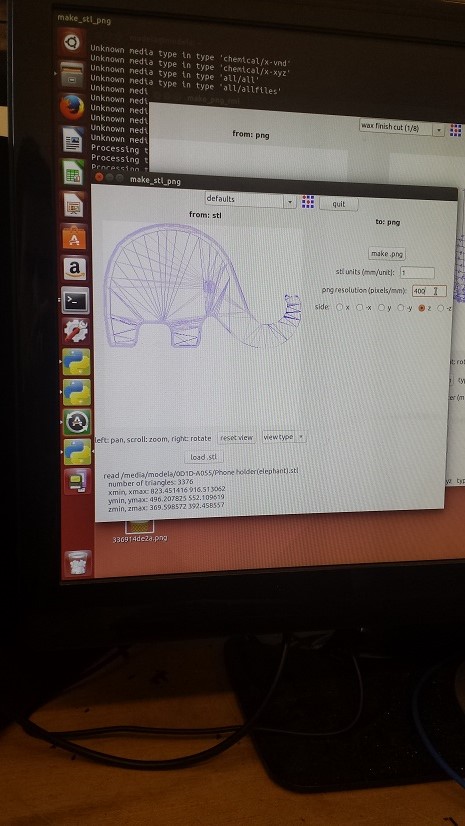

I tried using the modela first but it was not my week with this machine. From what I heard from other section mates there was a miss adjustment in the machine. So time for looking for an alternative. The shopbot it is.

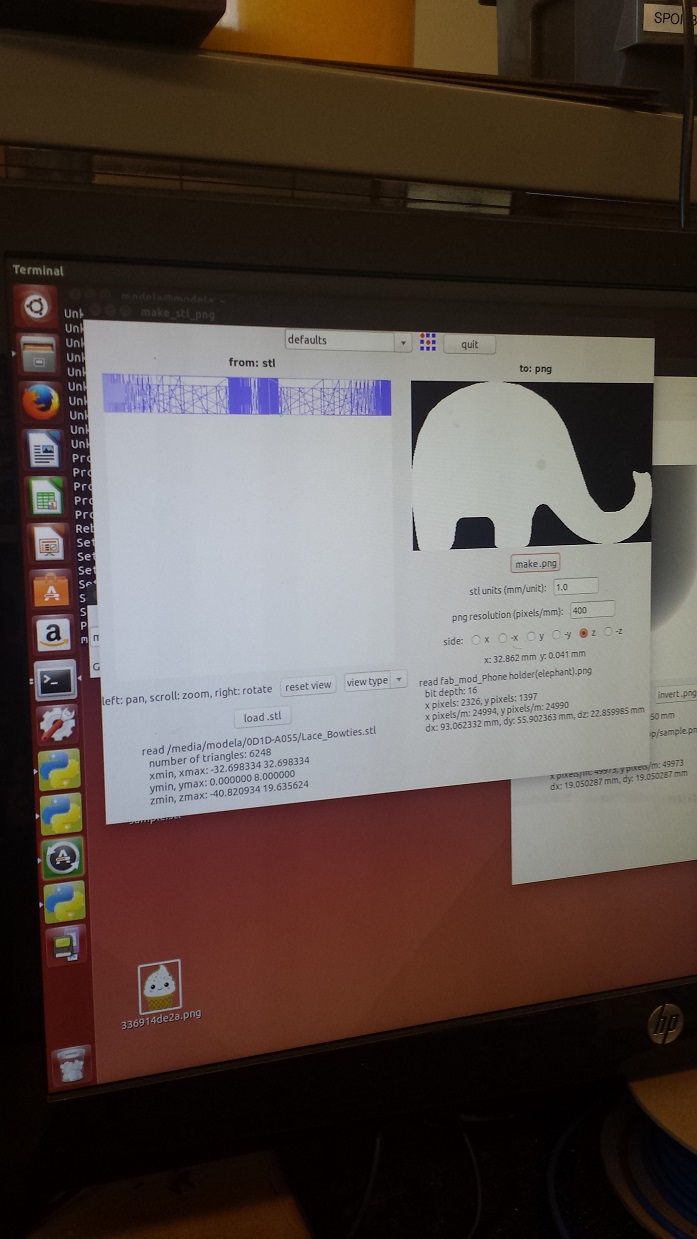

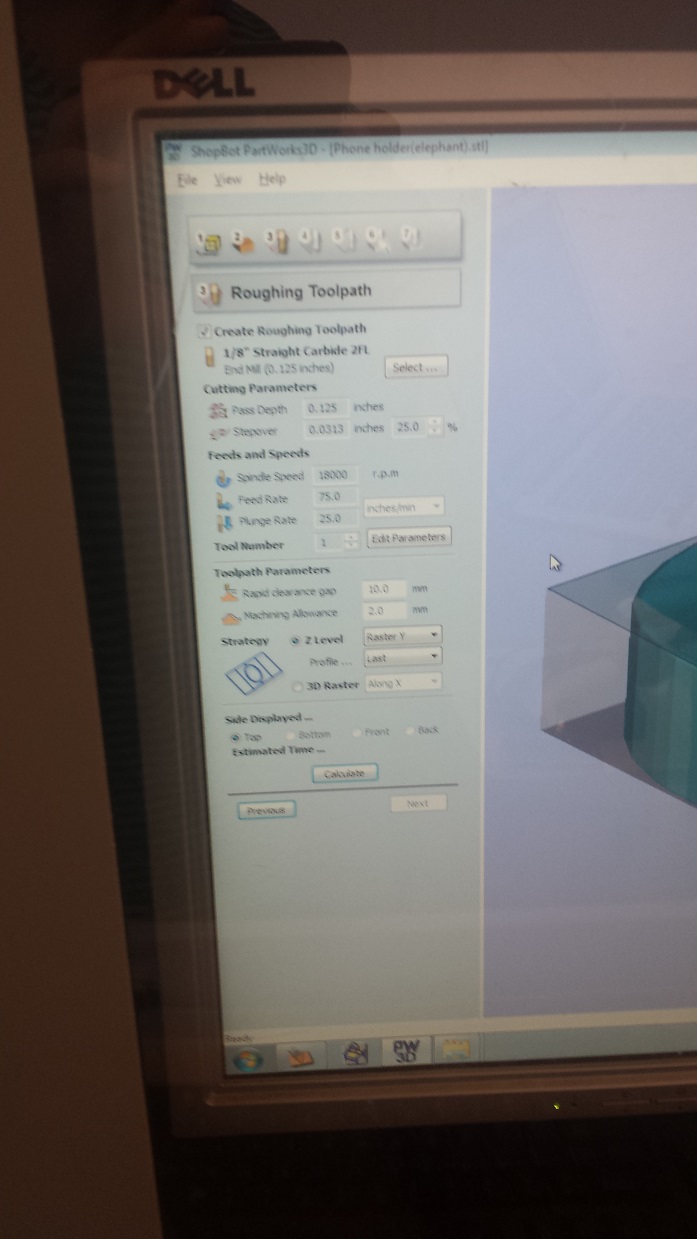

I saved the file and opened it in the shopbot Vcarvepro software. First step there is to set the dimensions of the plywood sheet. Revised the fillets and closed vectors. A heads up, when exporting from Solidworks, sometime there are lines that are repeated several times and that was causing an error window to pop up.

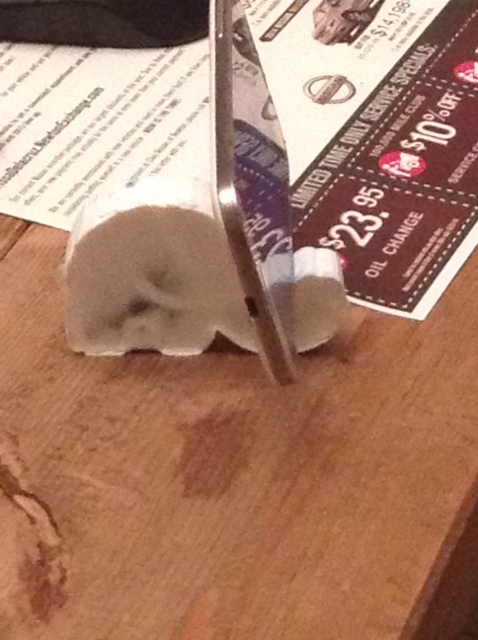

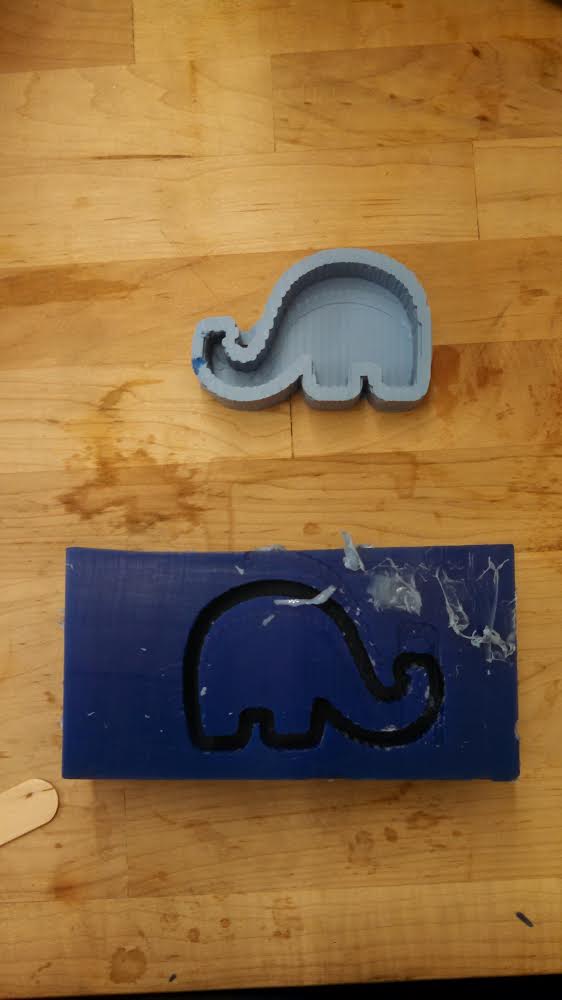

For some reason, even after zeroeing the machine, the route was not starting at "0". We had to play the machine a little bit so that it started at the correct point. As you can see in the photograph my mold suffered this inconvenient. But I believe is good enough to proceed for this week's assignment.

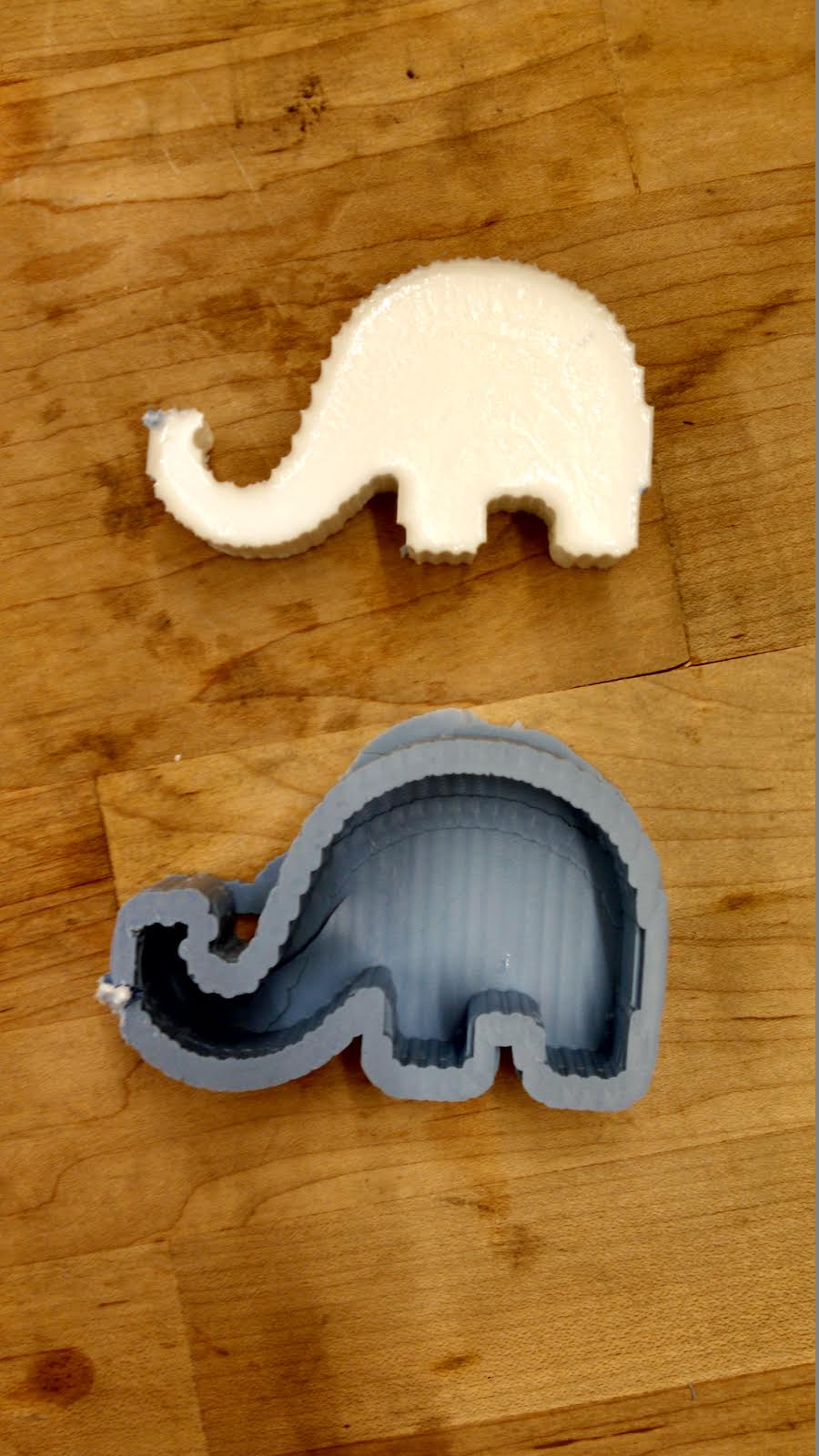

I ran into a defect with my first mold/cast. It seems I did not have enough volume of smooth-on on top of the casting what resulted in and orifice in my casted part.

After milling a negative mold again, seemed that I was good to go and avoid that problem. Let's see.

Yes, it worked! De molding was not complicated at all.

And here it is, my phone holder!