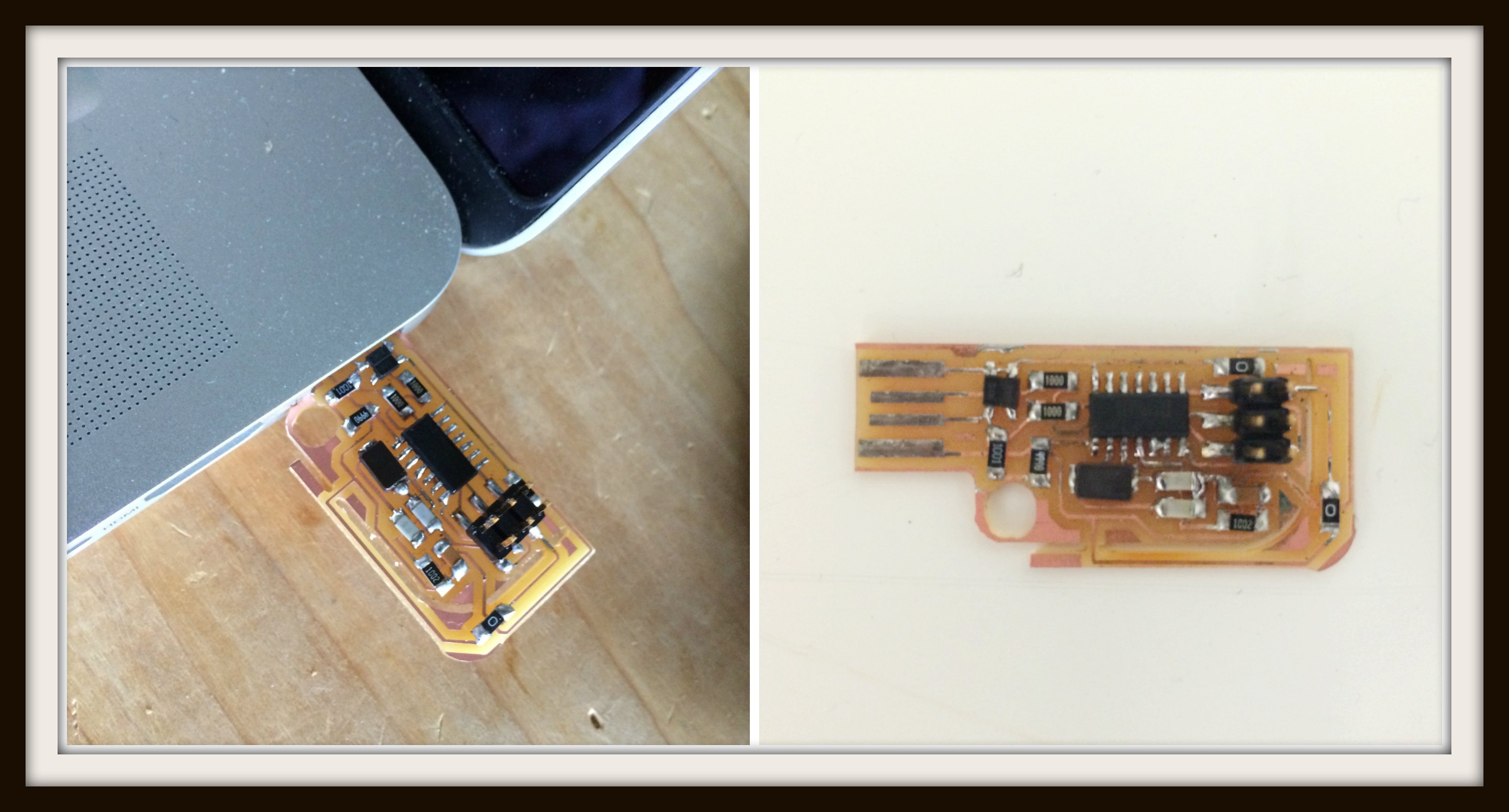

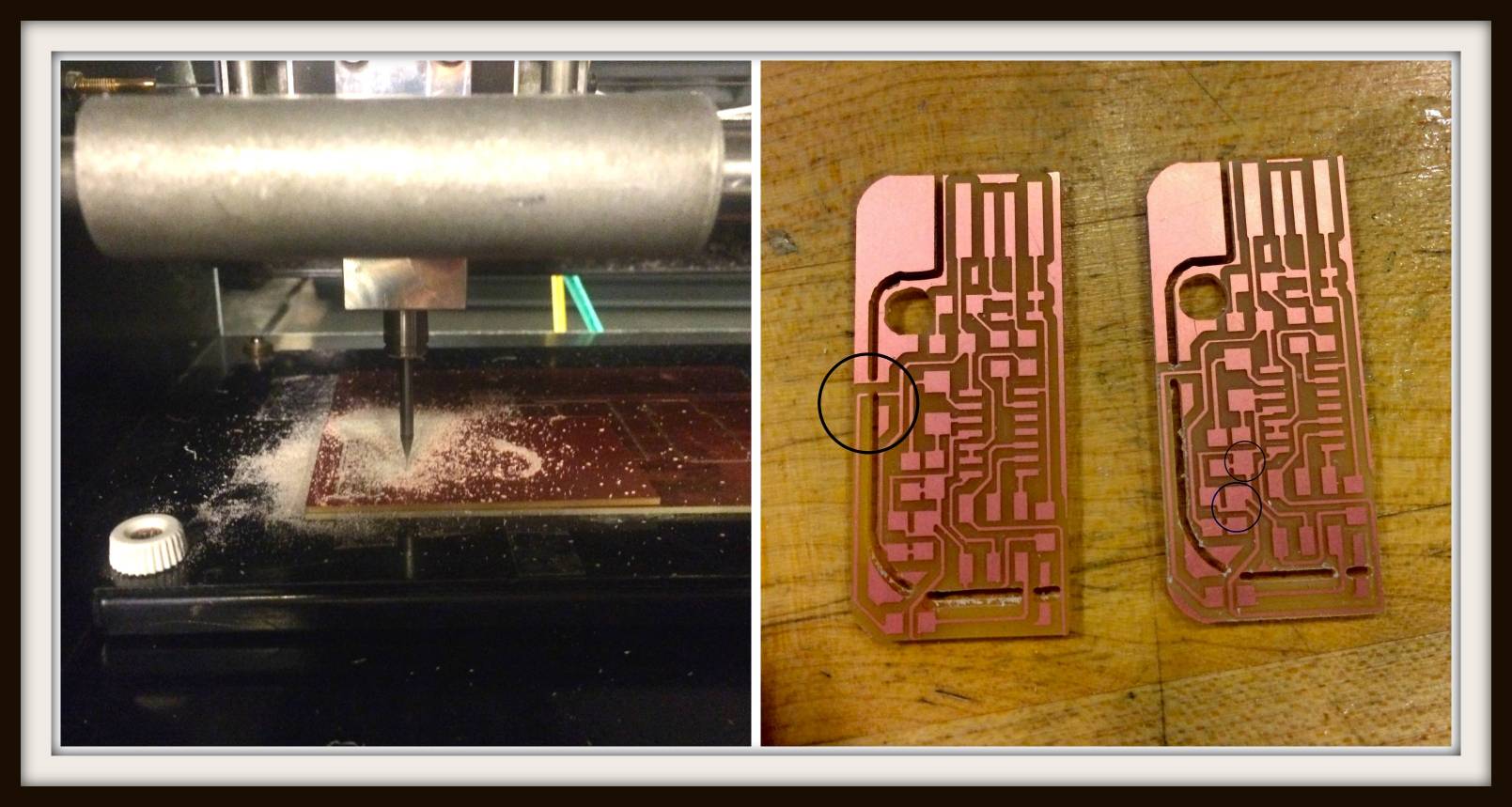

First, I milled my board based on Valentin's design. After replacing the 1/32 milling tool with the 1/64 milling tool, it appeared from my vantage point as though the milling tool was going over all of the 1/32's milling job! I got nervous about this, stopped the machine, and removed the board, only to find that it appeared to be doing what it was supposed to. I tried my best to replace the board and continue the job, but couldn't place the board back precisely enough, and wound up cutting through certain traces such as the one circled in the image to the upper left. Lesson: don't remove the board mid job! I then milled the board again, and thought everything had gone smoothly this time around. I'd later learn that there were at least 2-3 shorts on this board caused by improper milling of the design (two of them are circled in the upper right). Lesson: once your board is printed, take a GOOD few moments to examine the board next to the schematic and make sure everything is printed as anticipated!