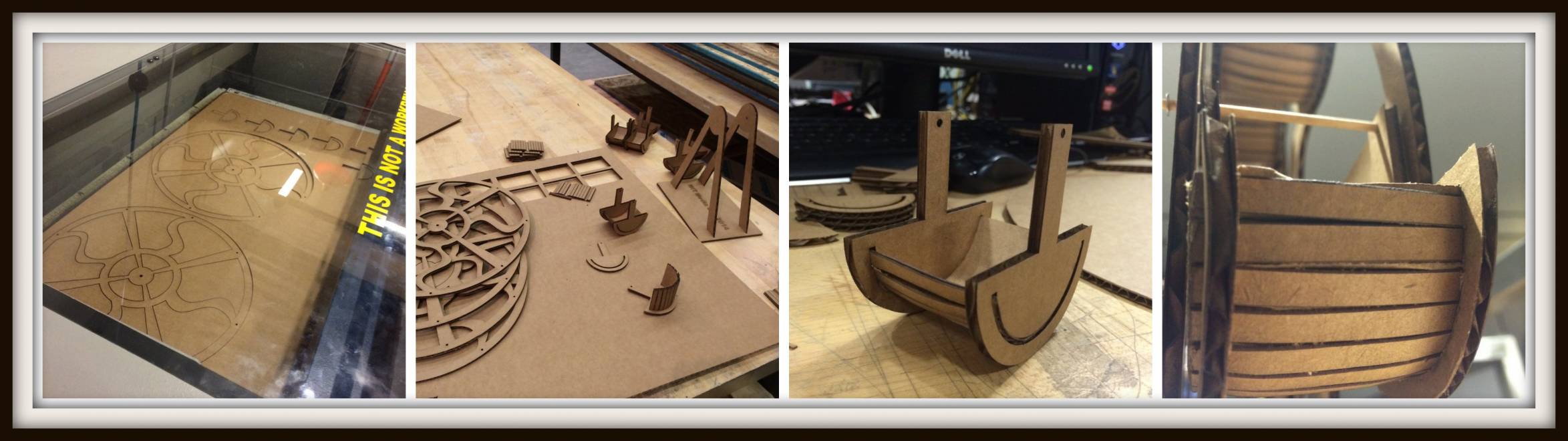

Of course, in order to get this spinning I needed to add some wooden sticks into the mix, and some washers to hold things in place. But otherwise I relied on cardboard pressfit for assembly. I began by mapping and assembling the parts on Solidworks (assembly pictured above). I could not bend the bases of the gondolas in Solidworks, and so I left them out of my model. This ended up backfiring since I failed to consider that the gondolas would sink below the wheel when coming around the bottom. Thus I had to reprint my wheel holders to be a few inches higher.

It took quite a few attempts to get the laser's power settings correct. I printed a handful of sheets that did not cut all the way through, and printed etches/cardboard scores with too great laser power. I also realized that increasing speed counteracts increases in power, and so you're best off leaving the speed alone and just adjusting the laser's power setting. Power=13 turned out to be the magic number for cardboard scoring (right-most image provides a detail of the gondola base). I also didn't quite make my slots the right size. If I had more time I'd certainly widen the slots and reprint, but cardboard is very forgiving and so I managed to assemble the parts nonetheless. I also forgot to account for the wooden stick width when determining how wide my wheels needed to be. This means that the wheel currently only spins a bit. There is a simple fix- If I have time to reprint the base with slots further apart, then I can widen the wheel. This all goes to show how useful it is to generate complete assemblies in Solidworks before printing! (if only I could figure out how to bend things in Solidworks...)