Molding and Casting: Chopsticks and chopstick rest

Love me some sushi.

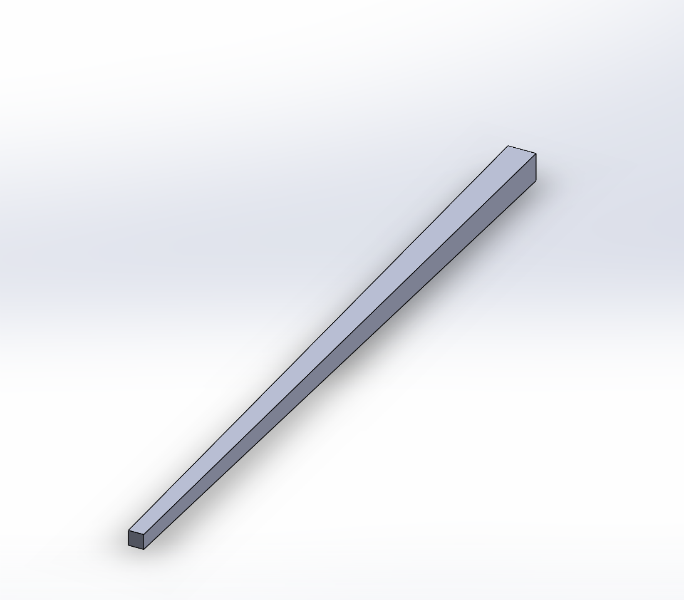

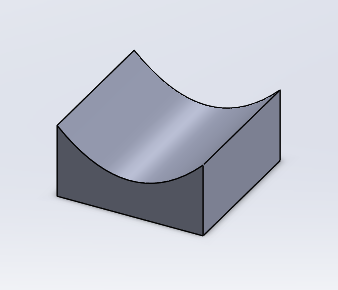

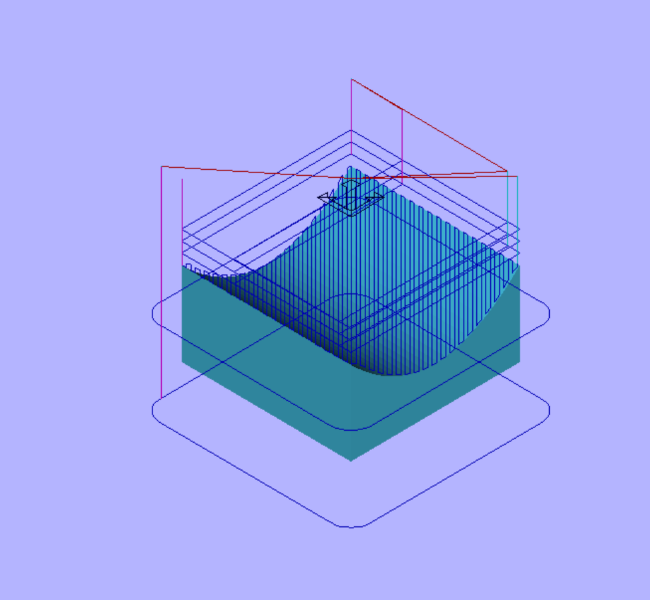

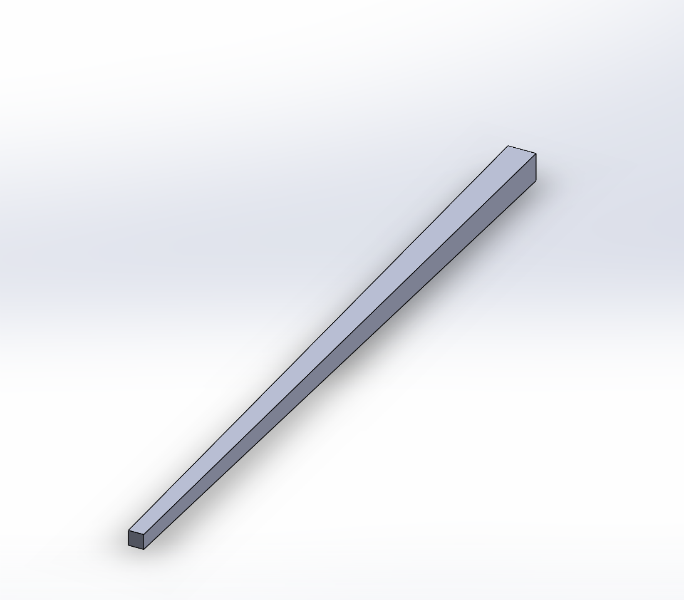

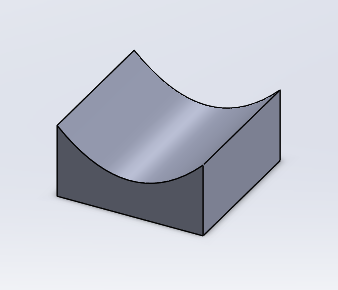

So I decided to make chopsticks and a chopstick rest. I CADded them in solid works.

So I decided to make chopsticks and a chopstick rest. I CADded them in solid works.

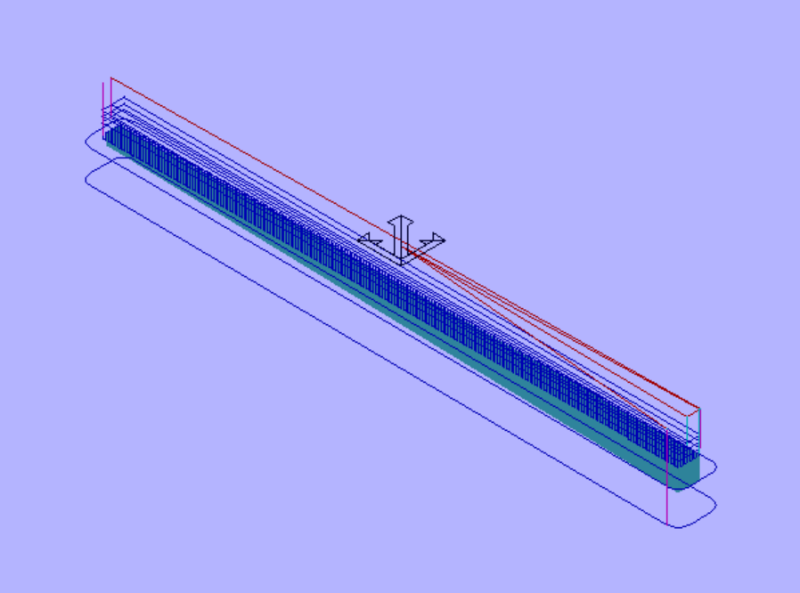

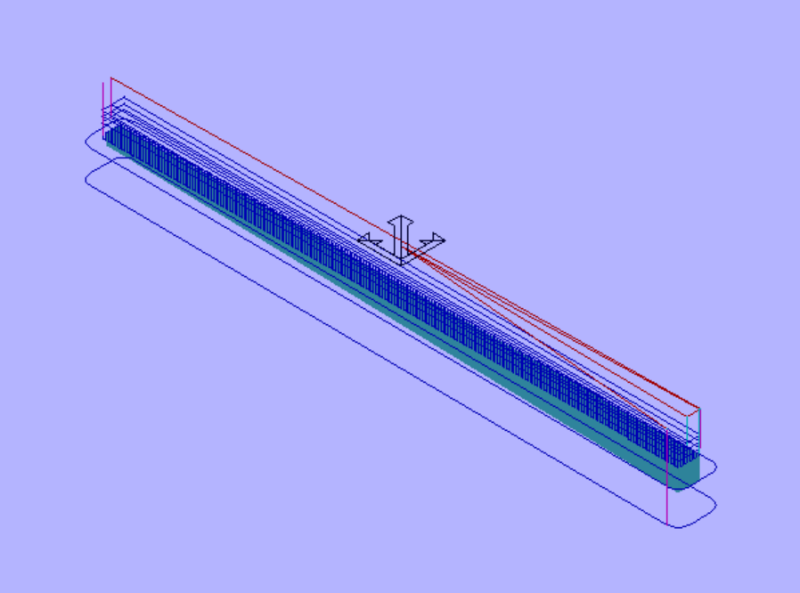

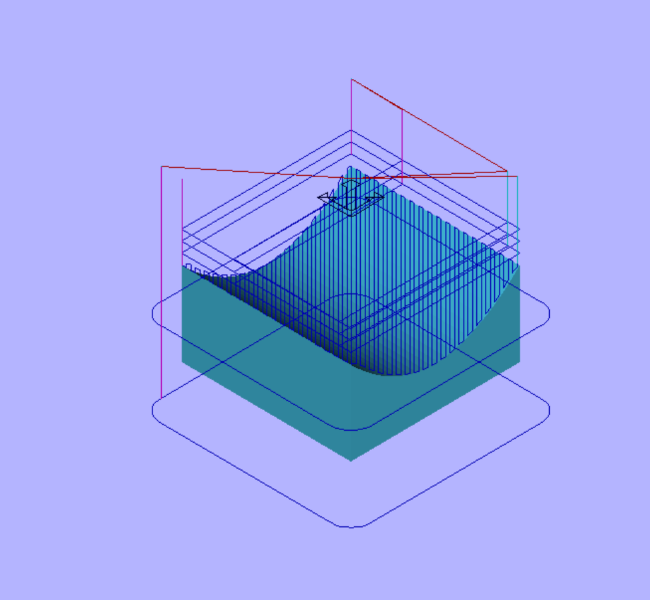

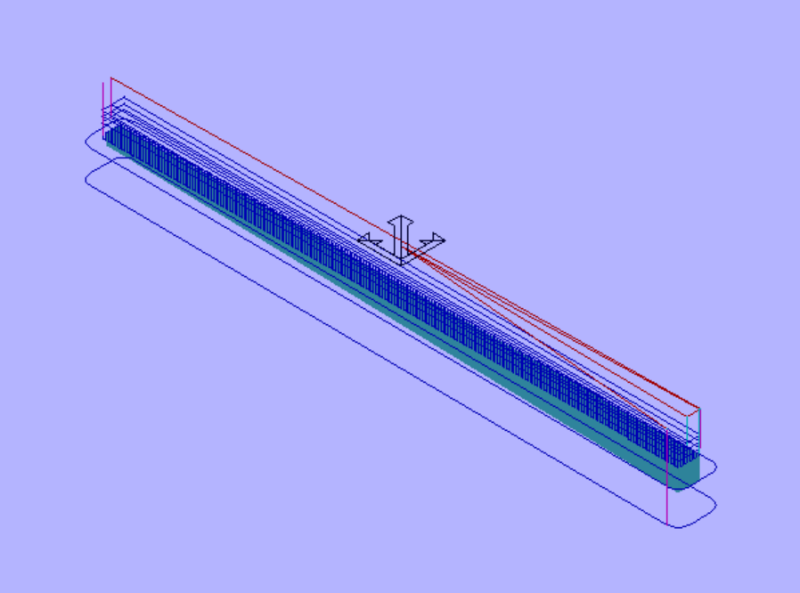

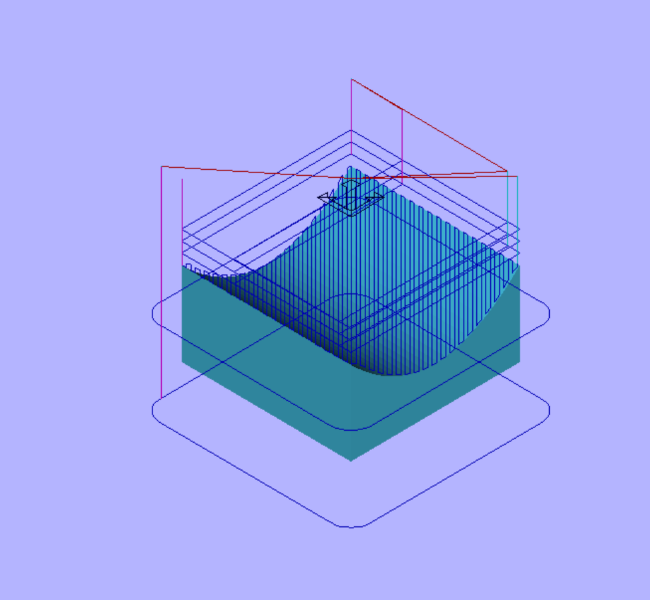

Then I made the tool path to make the molds in Part Works 3D, making sure to cut out around

the parts (to make the walls of the mold).

Then I made the tool path to make the molds in Part Works 3D, making sure to cut out around

the parts (to make the walls of the mold).

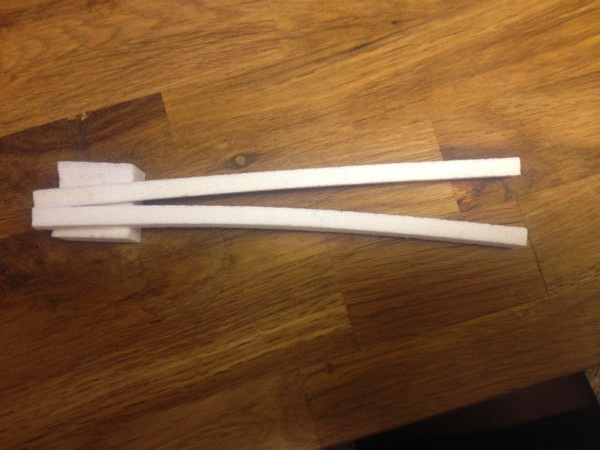

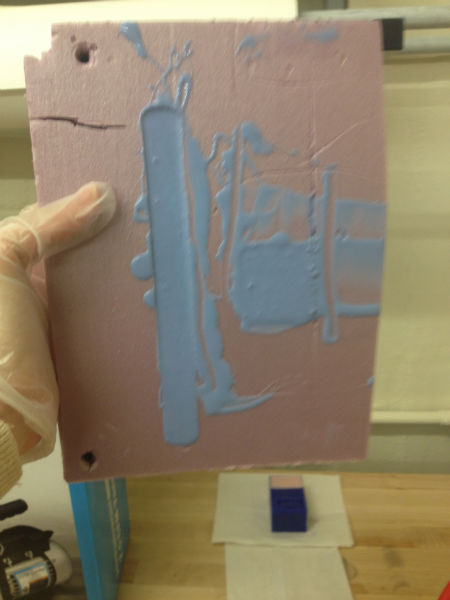

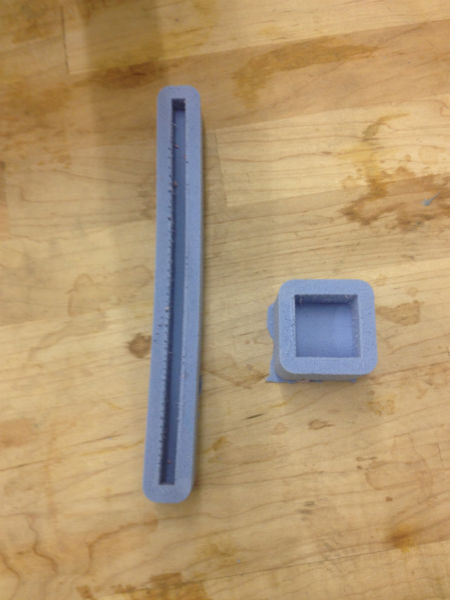

Then I cut using the gearlab Shopbot and Shopbot software out of machinable foam.

Then I cut using the gearlab Shopbot and Shopbot software out of machinable foam.

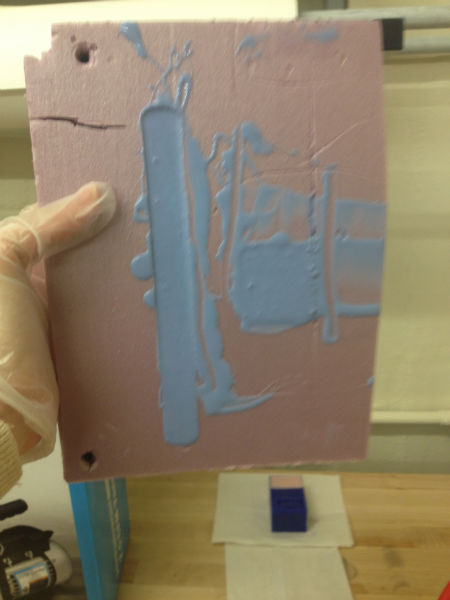

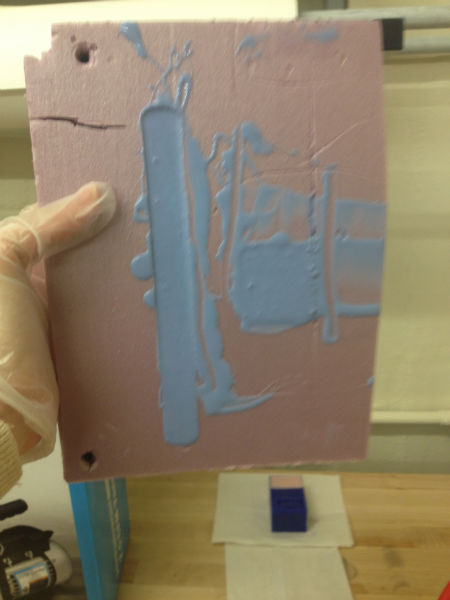

Then I used the OOMOO 30 to make the mold. As you can see, before it cured there were bubbles

apparent.

Then I used the OOMOO 30 to make the mold. As you can see, before it cured there were bubbles

apparent.

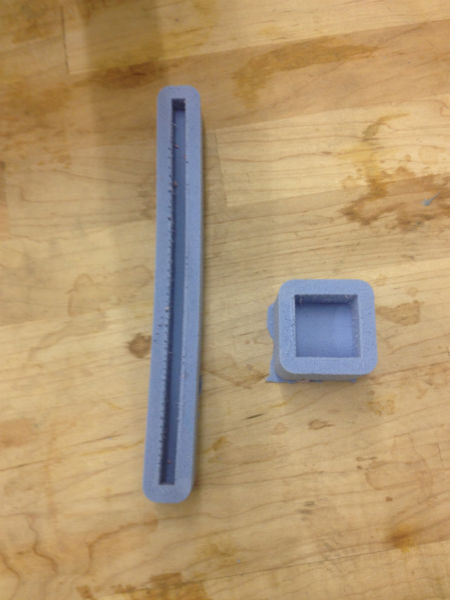

I left it to cure overnight and the bubbles went away.

I left it to cure overnight and the bubbles went away.

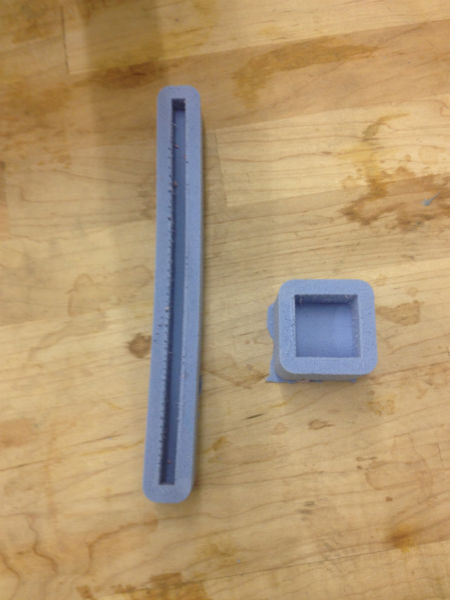

Then I popped out the molds by cutting away at the foam and prying them up with my fingers.

Then I popped out the molds by cutting away at the foam and prying them up with my fingers.

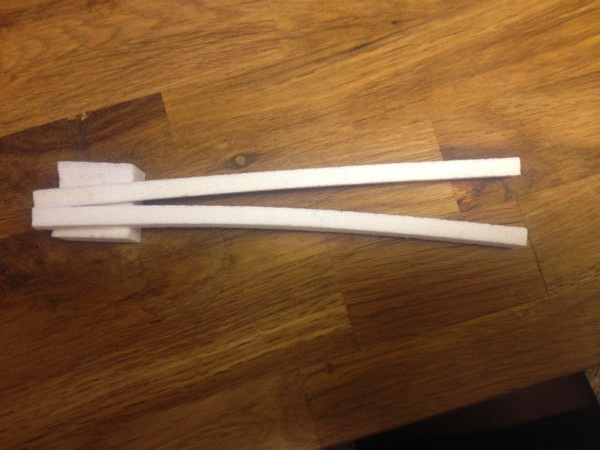

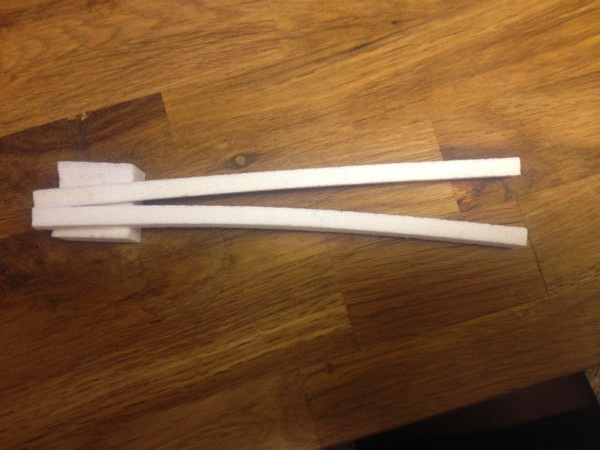

Then I used the Smooth-On plaster to make the chopsticks and rest. It took about 20 min to cure.

Then I used the Smooth-On plaster to make the chopsticks and rest. It took about 20 min to cure.

For the second chopstick I got creative and bent the mold ever so slightly as it was setting

to get a more ergonomic feel. I then sanded, and voila:

For the second chopstick I got creative and bent the mold ever so slightly as it was setting

to get a more ergonomic feel. I then sanded, and voila: