Week 01 Final Project

Wheelchair Wheel Cleaner

My final project is to build a cleaner that fits on a wheel. In East Asia, where it is customary for people to take their shoes off at home, it is a huge hassle for wheelchair users to wipe our wheels every single time we get into our houses from outside. It can take as long as ten minutes to clean all four wheels. I want to minimize this time by bringing to life my idea for an intuitive and simple device that will perform this job quickly.

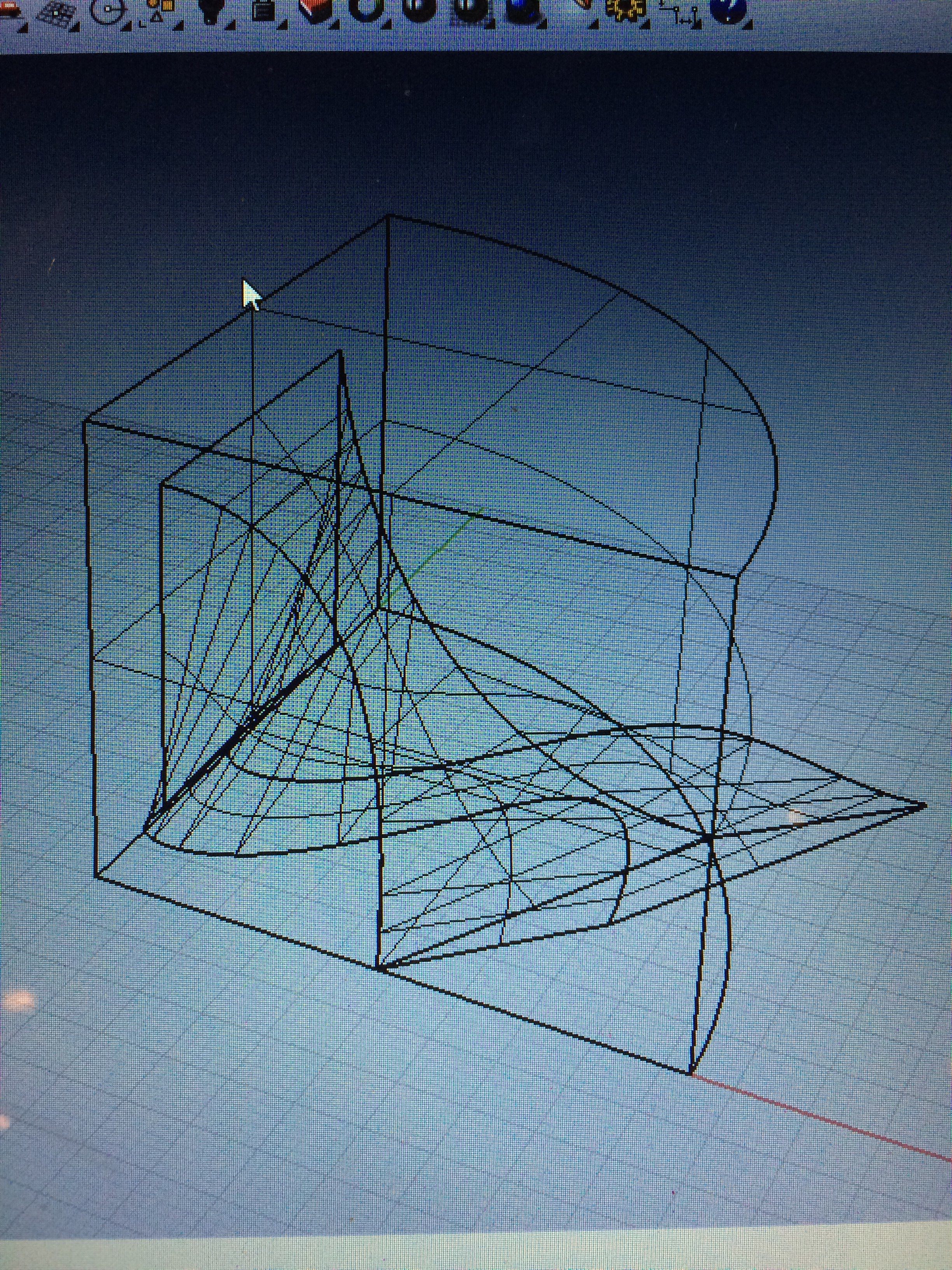

This It will be a shape like this and inside will be hollow so that a wheel can fit in. However, I haven't learned how to do that in solidworks. I hope I can do that in a few weeks.

From this experiement, I somewhat understood the best material I need to use to make a wheelchair wheel clearner. It seems like for my wheelchair type, or regular manual wheelchairs, scrub sponge would be good enough. Since they had the hard surface side and soft side. Also this material would be good to absorb water and be efficient enough to clean the wheel.

Analyzing the types of manual wheels, the thickness of the wheel is generally about an inch. Thus the wheelchair wheel cleaner needs to have at least an inch of width. Also I would like the wheel cleaner be attached to the wheel and when the user wheels forward, the cleaner which was installed at the top of the wheel would go down as the wheel circles and stay on the ground level and as the wheel circles, it would clean the wheel with friction.

First I made a wheel that is equivalent size of my actual wheelchair to make a wheel cleaner's surface to that of the surface. The surface will be touching the wheel so that it can clean the wheel. As it can be seen from the drawing, I thought to have the wheel cleaner on the bottom of the wheel, so that when I wheel, it cleans by itself. It will have a rod that a wheel can roll on to, to prevent it from rolling over the cleaner.

The size of my wheel as 22 inches

my initial design was this. However, the problem that I encountered was that it does not roll on the rod since my weight and the weight of the wheelchair were just too much for that little rod to roll on. I couldn't find a big enough rod at the lab, so I had to redesign and rethink about the cleaner.

I thought to keep the design, but to make it instead be attached to the break so that it stays on the wheel as it rolls.

These are some development of the wheel cleaners as I'd designed and tried on my wheel.

I made a little hole in the middle so that the srub can go in to clean the wheel as the surface of the wheel scraps the surface of the wheel cleaner.

I designed a board that would make LED lights light up the wheel. Sometimes it might be difficult to see the wheels cleaning when it's dark. I made LED lights light up when the button is clicked. Milling was the most difficult part as it took about 4 hours as I had not estimated. I had problems with the 1/64 an 1/32 and also with the z axis. Moreover, I once again had problem with the tapes as I made some parts thicker than the other. This I guess is crucial to the success of the milling because as you might have noticed, when one thing gets messed up, everything starts to pilling up and make you frustrated. Then Whalla, so many problems coming and coming.

THis is the final product!! it sits on my wheel perfectly and shines when I click the button. And more importantly, the LED lights are just small enough not to touch the wheels! PERFECTO!!