This week is “composites” week. The provided materials were burlap and epoxy resin. The basic premise is to layer

burlap and epoxy on top of a mold, and then add pressure to compress the burlap.

I decided to make a “hat,” and I actually found a perfectly-sized bowl to serve as the mold:

Laser-cut burlap

|

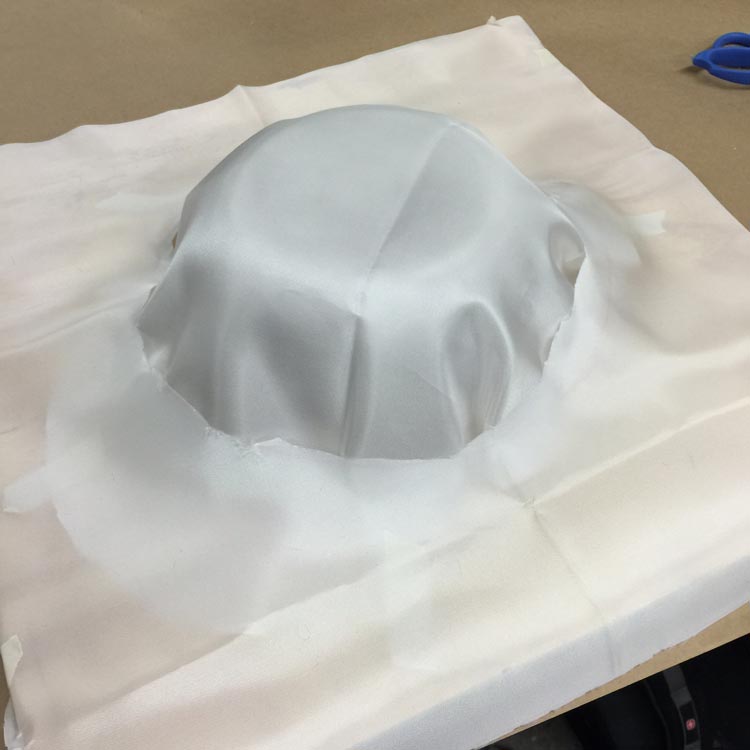

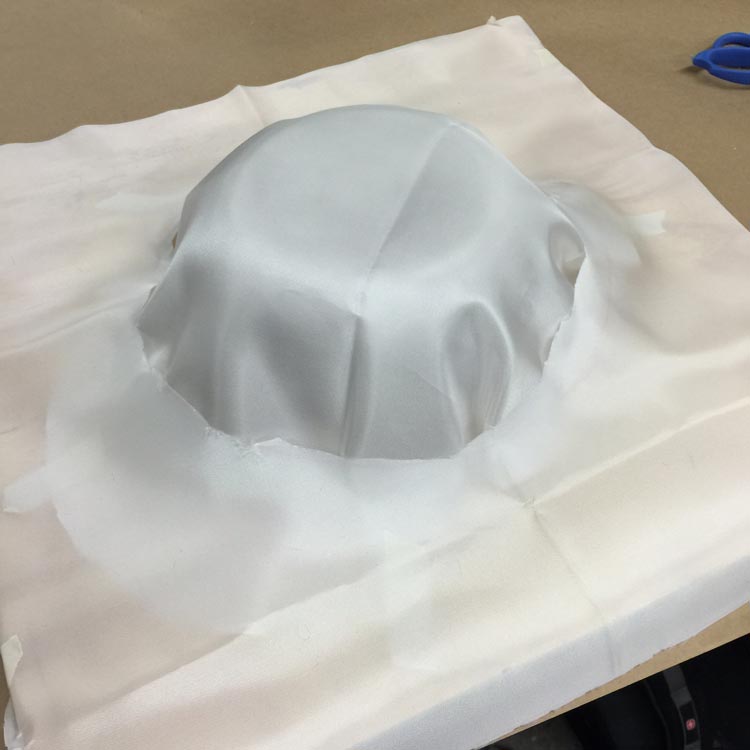

First layer on the mold is a 'release plastic'

|

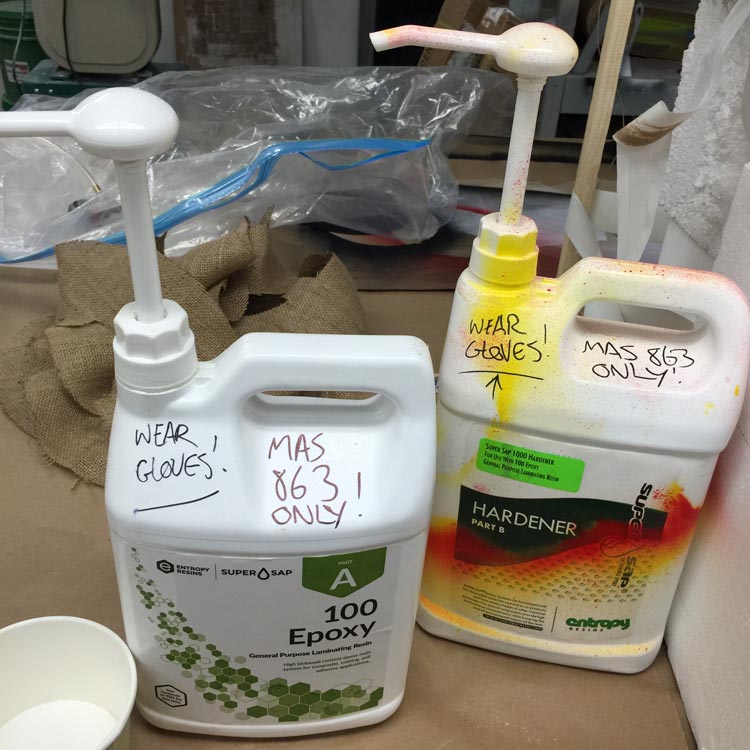

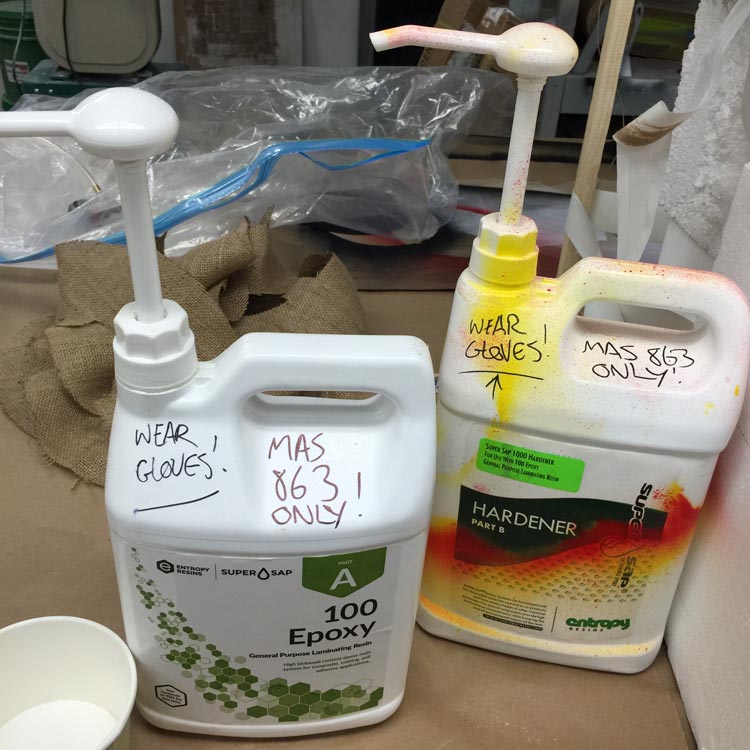

The resin that we used. 1 pump of hardener for 2 pumps of resin.

|

Seal the entire composite in a vacuum bag for 4 hours.

|

The hat needed some help to get come off of the mold!

|

Matt vs bowl

|

The final hat!

|