HOW TO MAKE (ALMOST) ANYTHING_MAS.863/4.140

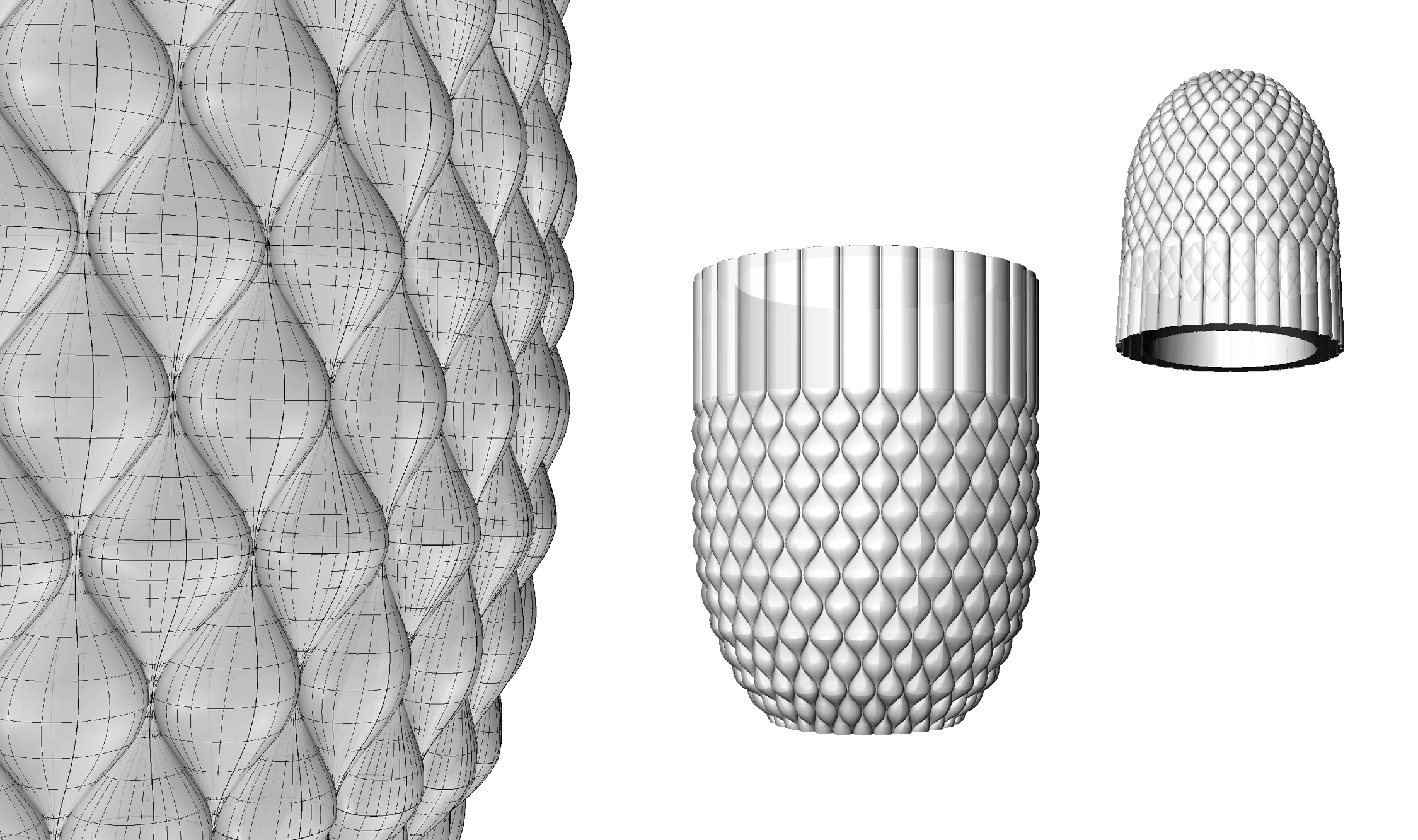

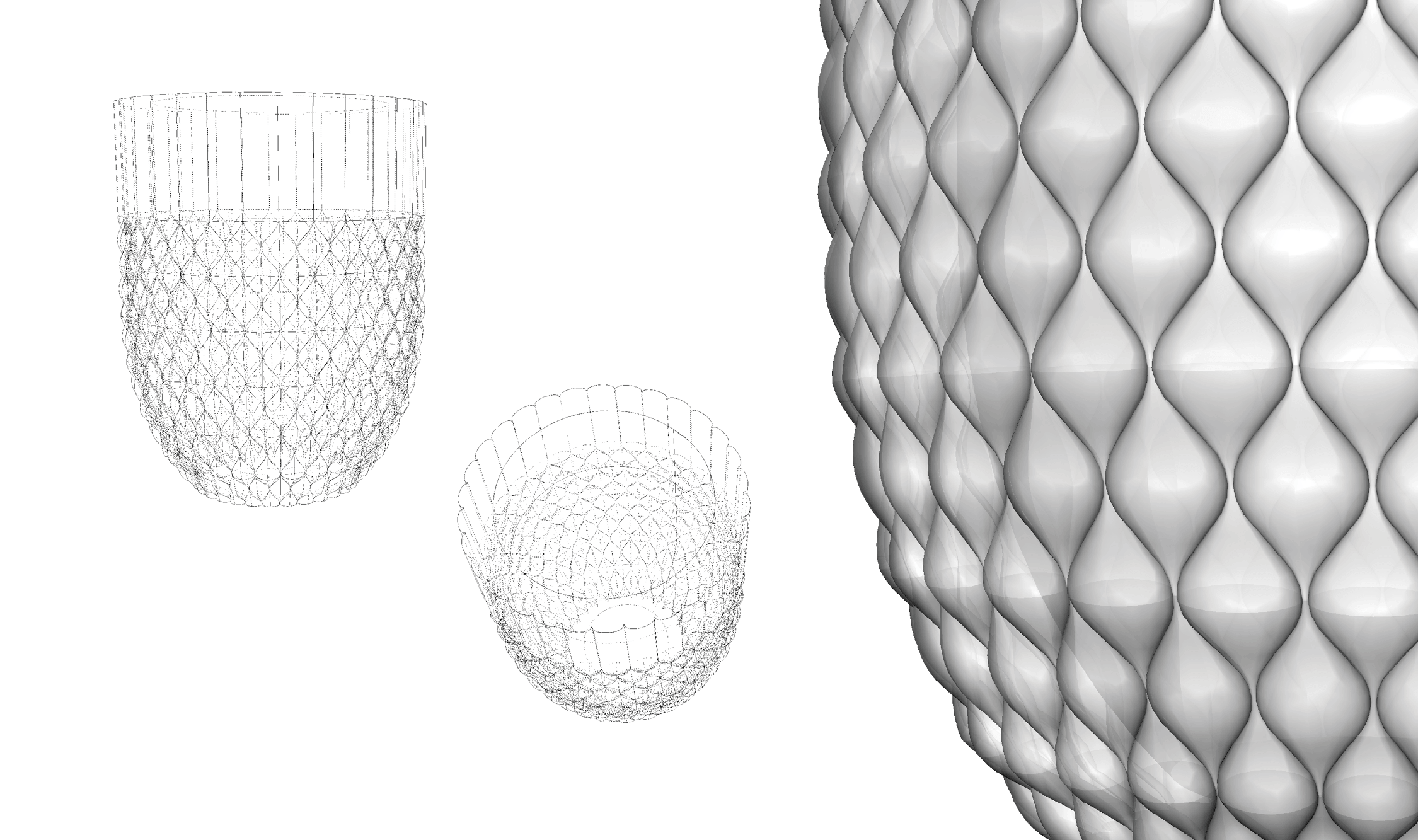

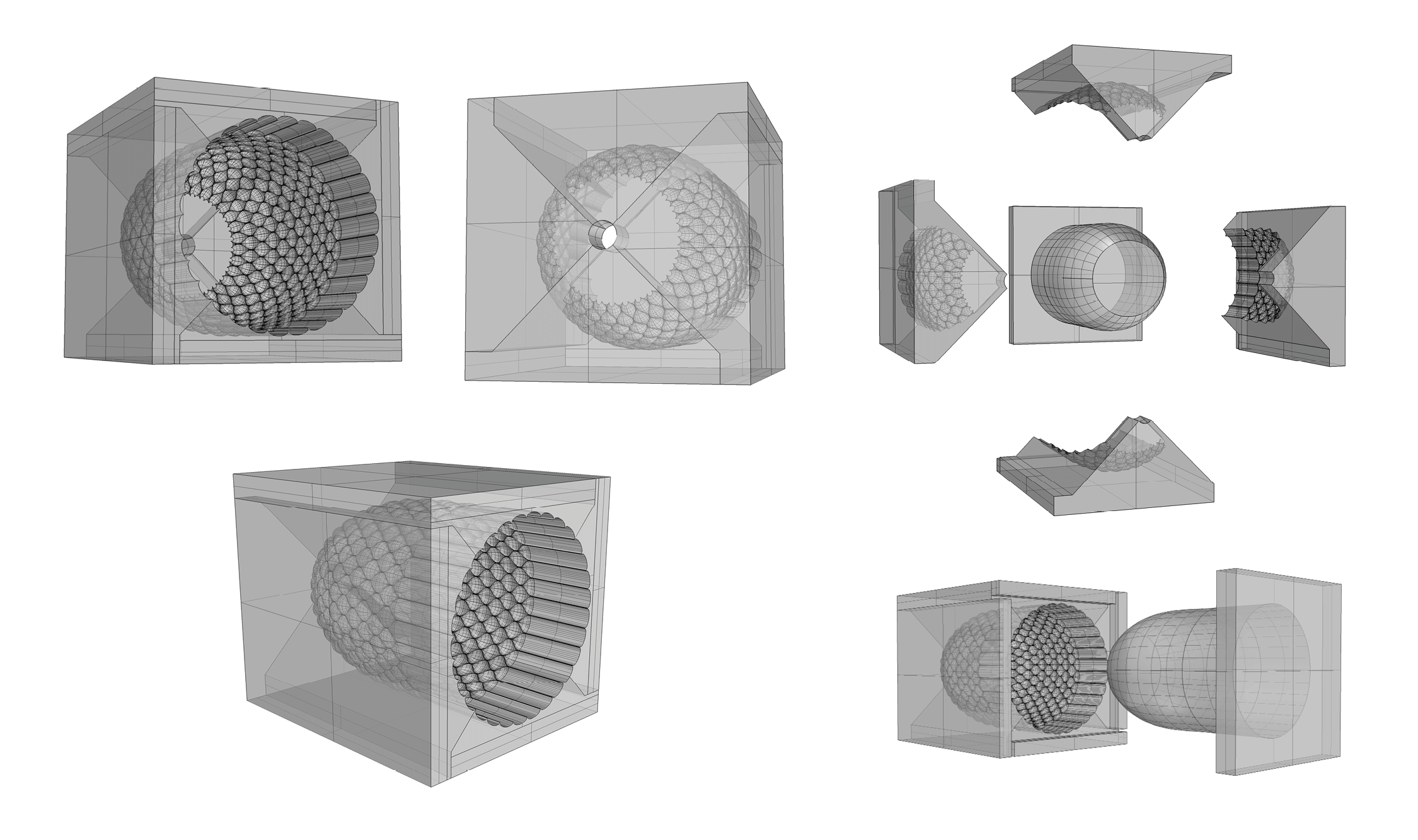

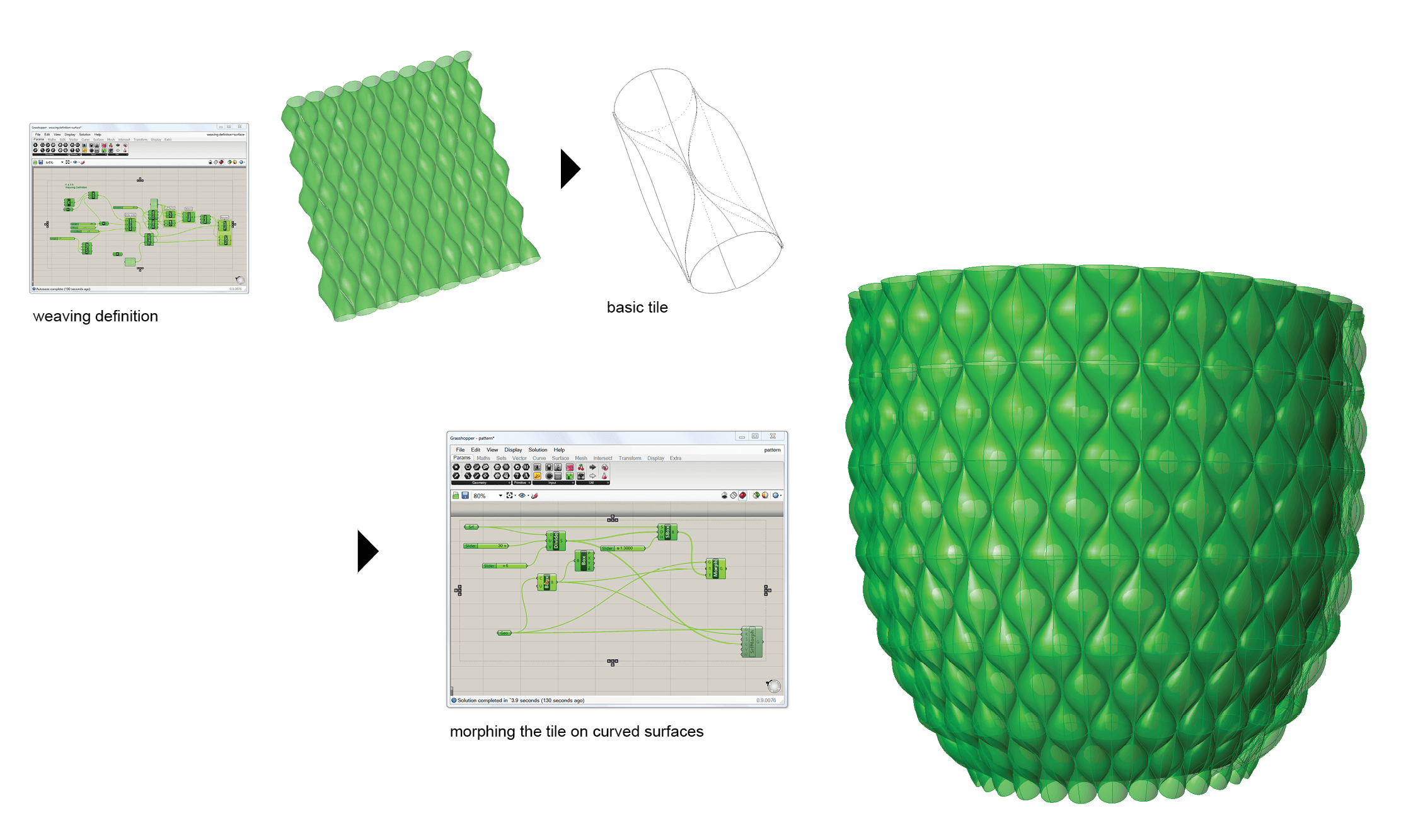

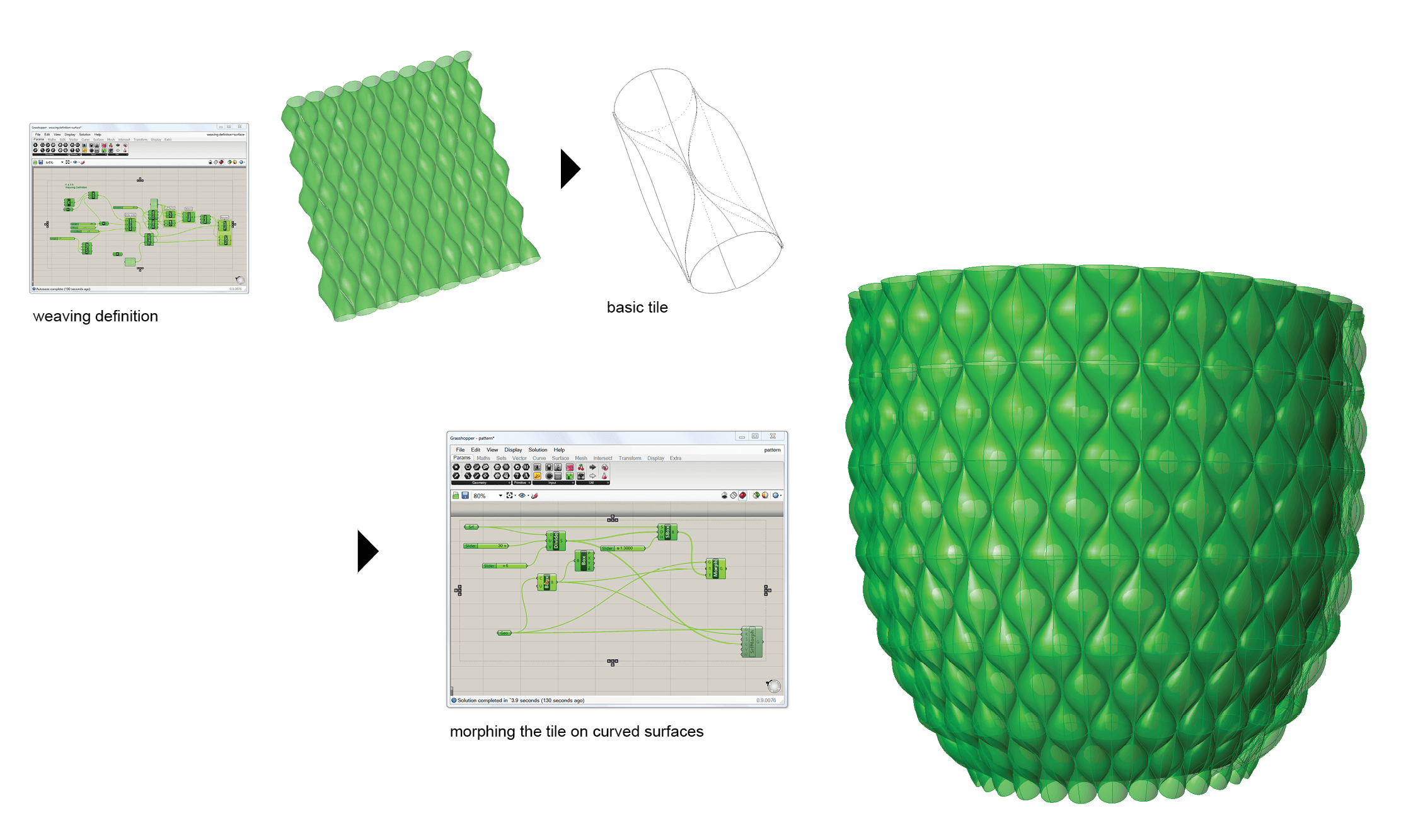

For this week assignment I wanted to mold and cast an object with a 3d pattern. I downloaded a weaving definition for grasshopper, and played with it a little bit. Then I wanted to be able to apply that pattern on any 3d surface, so I extracted a basic tile from the pattern, and wrote a grasshopper definition that enables to morph the tile on any kind of surface.

For this week assignment I wanted to mold and cast an object with a 3d pattern. I downloaded a weaving definition for grasshopper, and played with it a little bit. Then I wanted to be able to apply that pattern on any 3d surface, so I extracted a basic tile from the pattern, and wrote a grasshopper definition that enables to morph the tile on any kind of surface.

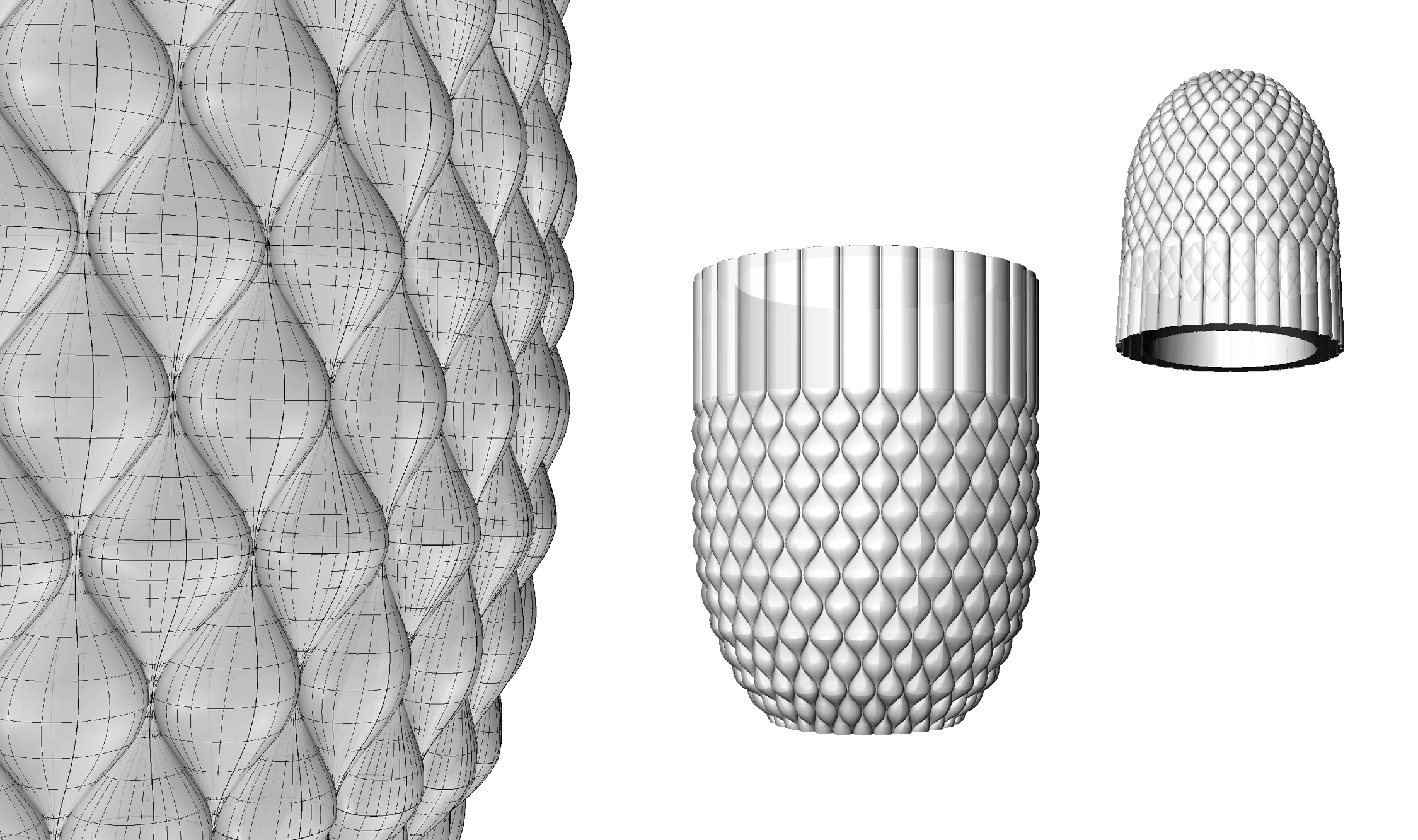

Next, I designed a small cup to be molded and casted

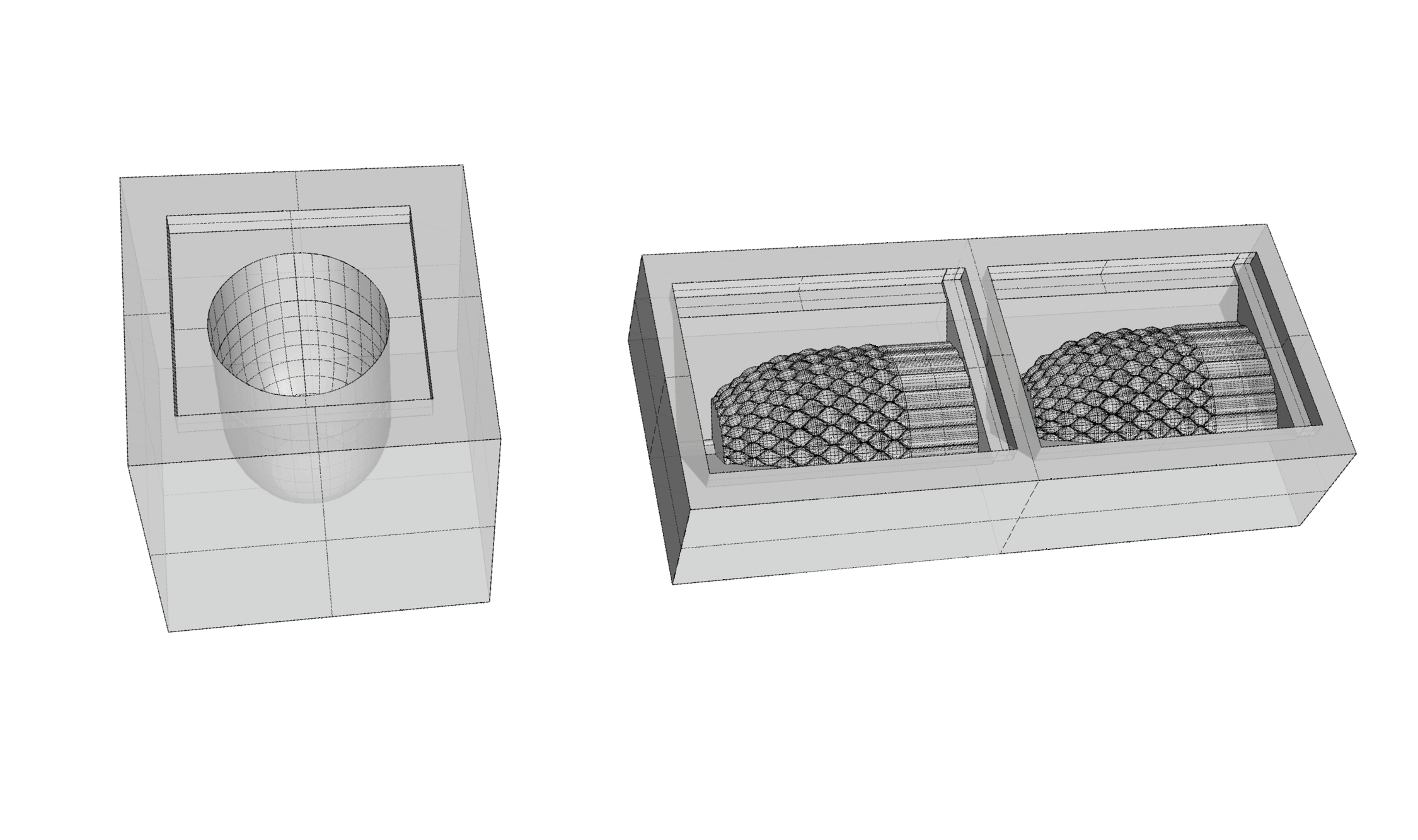

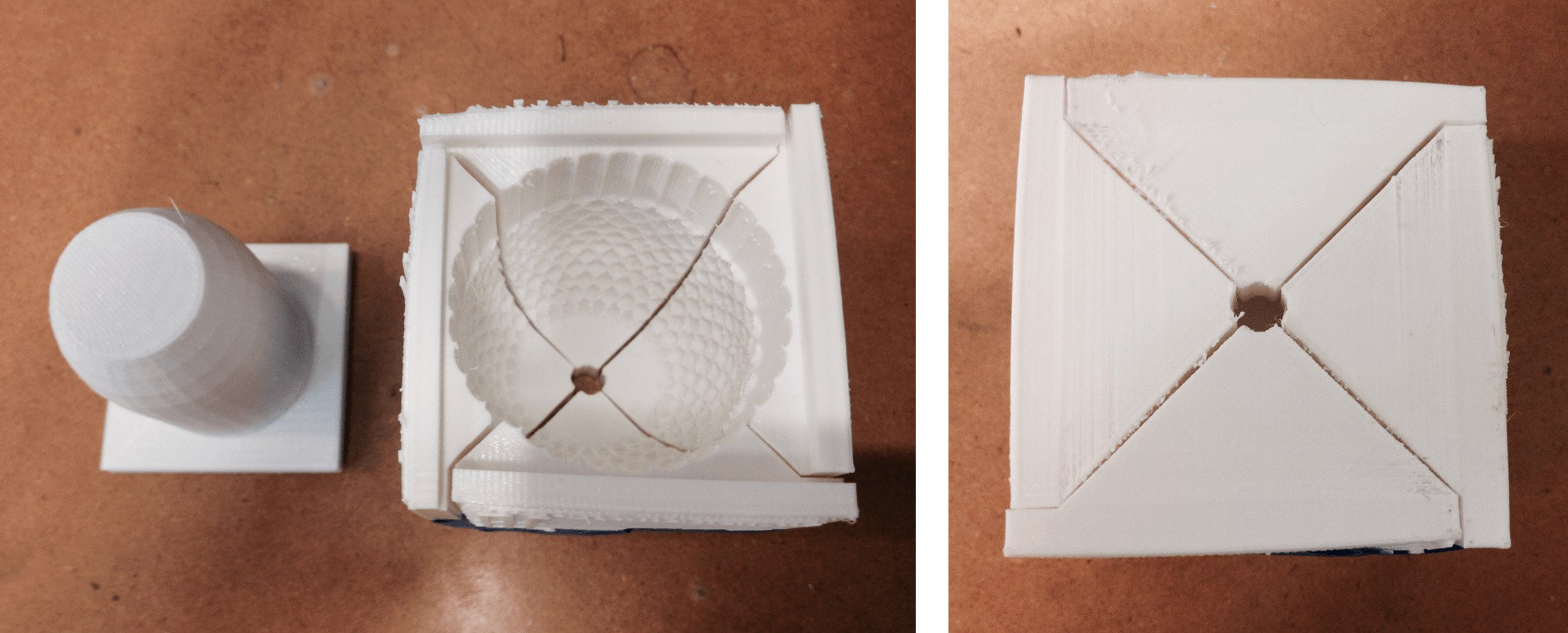

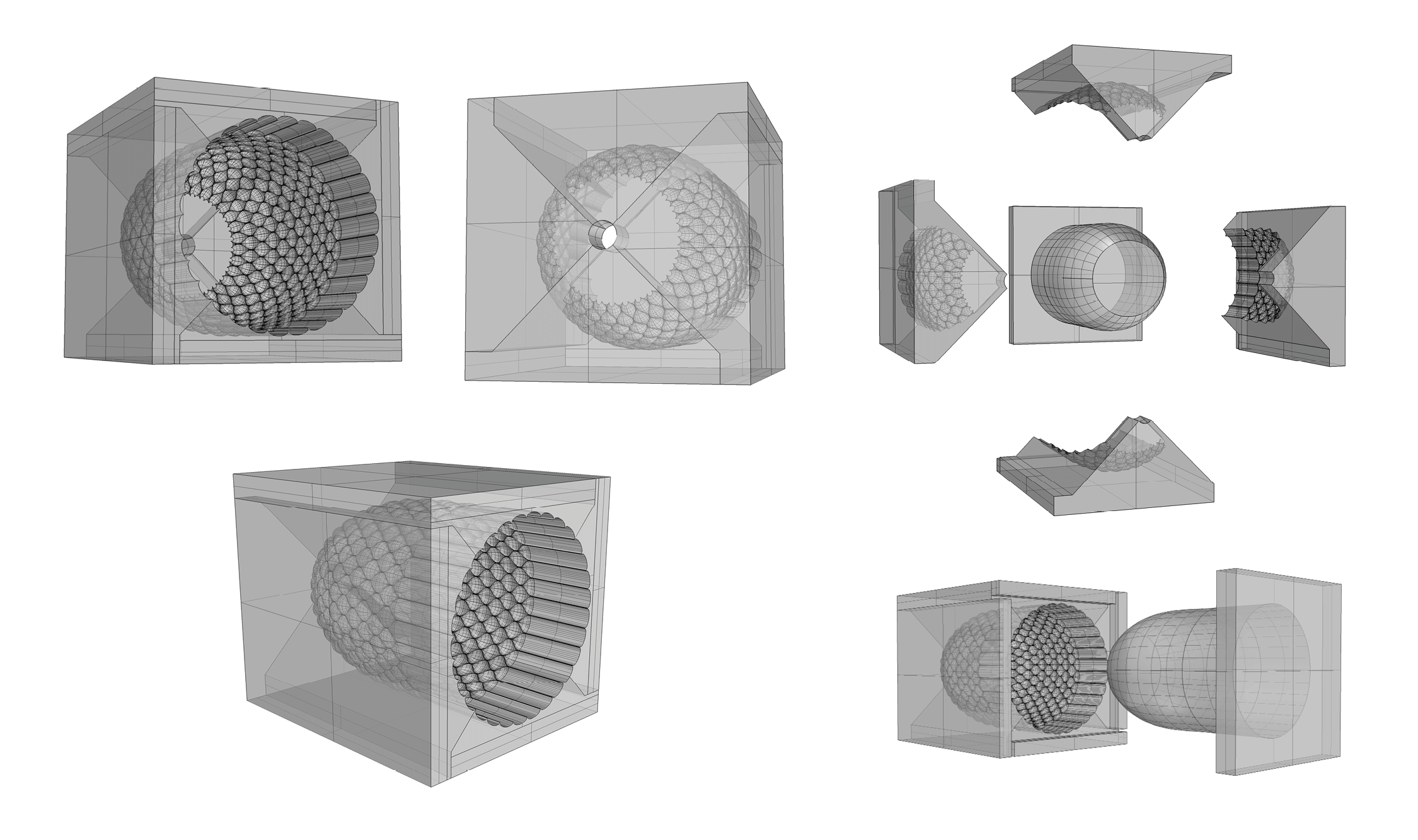

After a lot of thinking and trying (and some advice form David, the TA), I decided to make a 5 parts mold

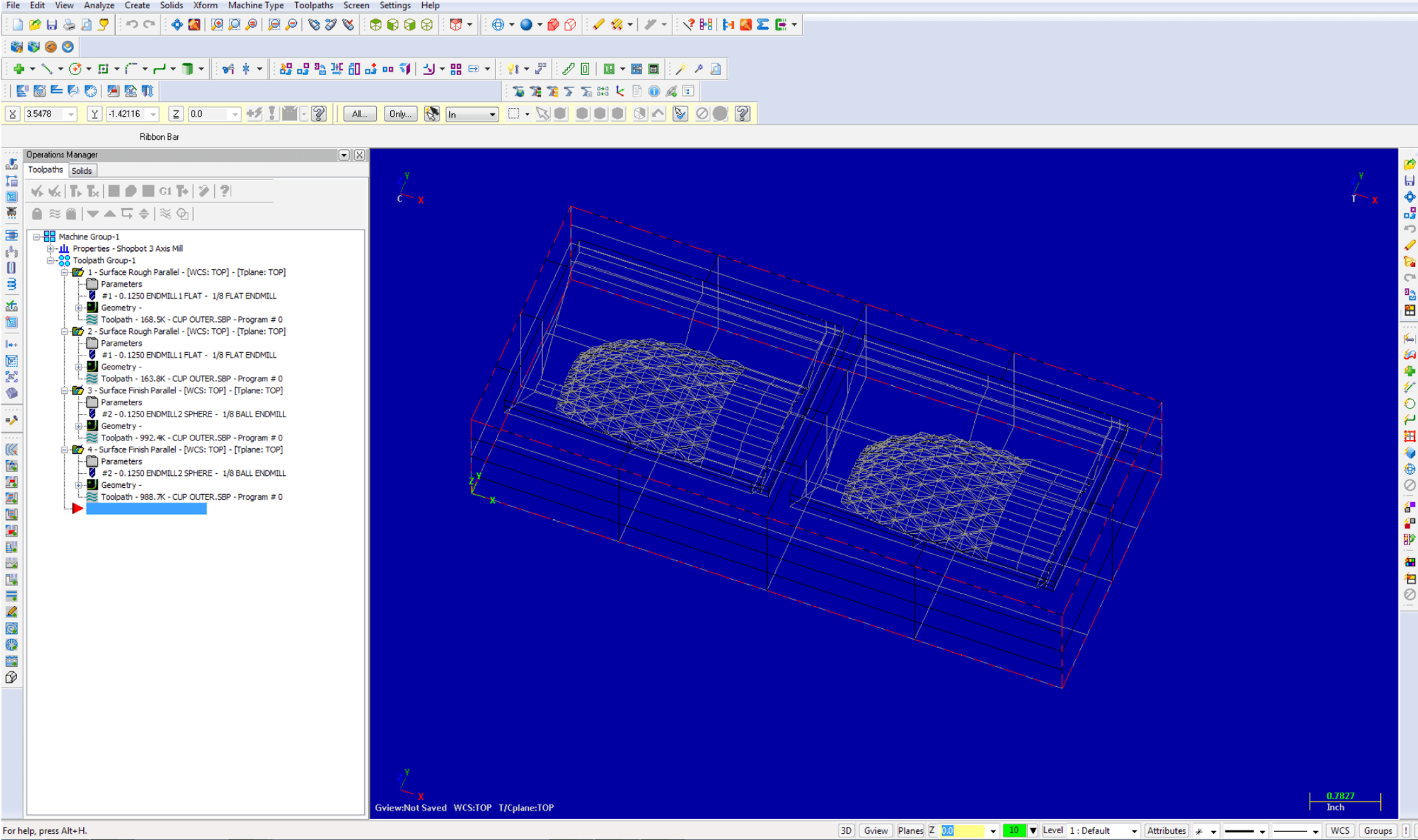

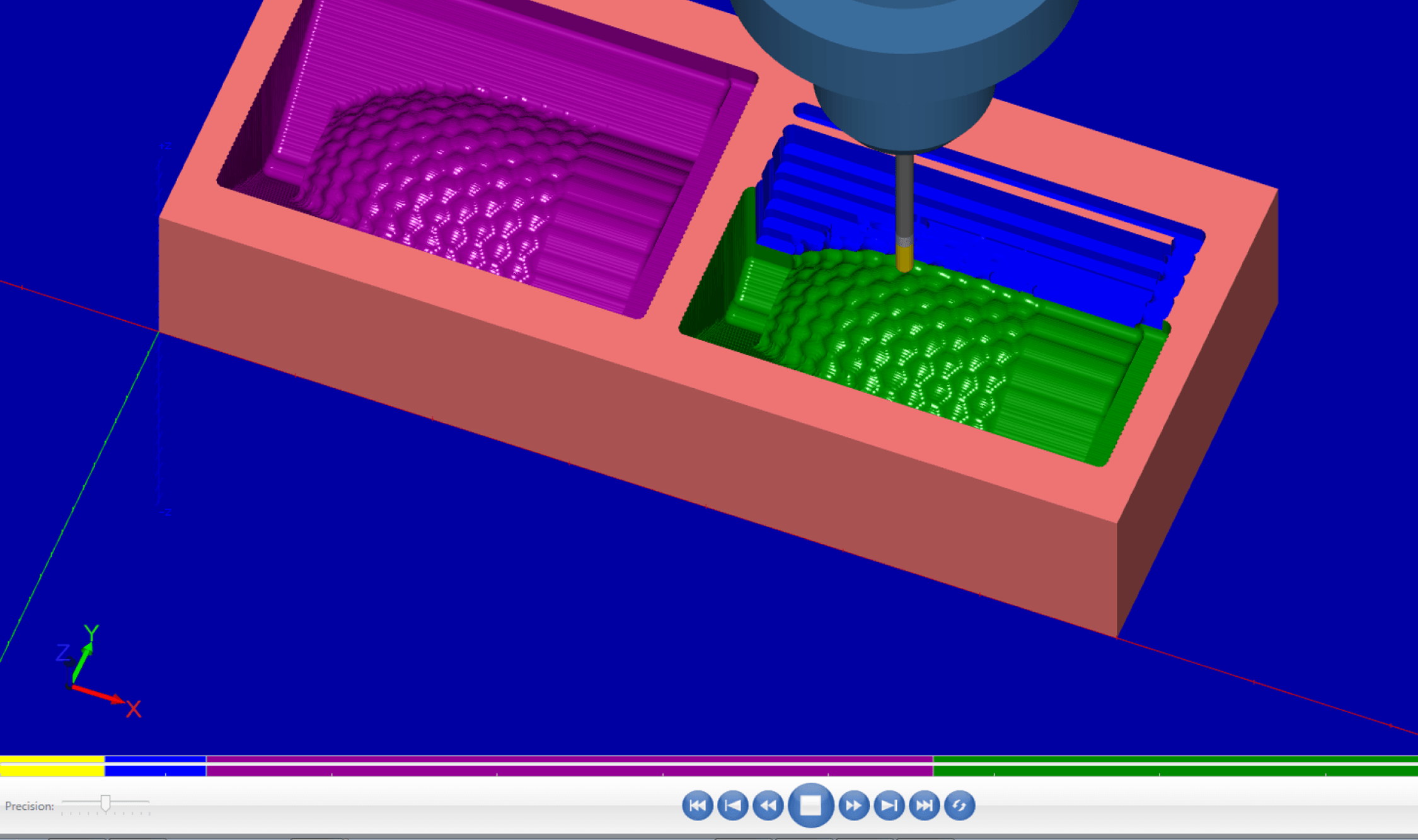

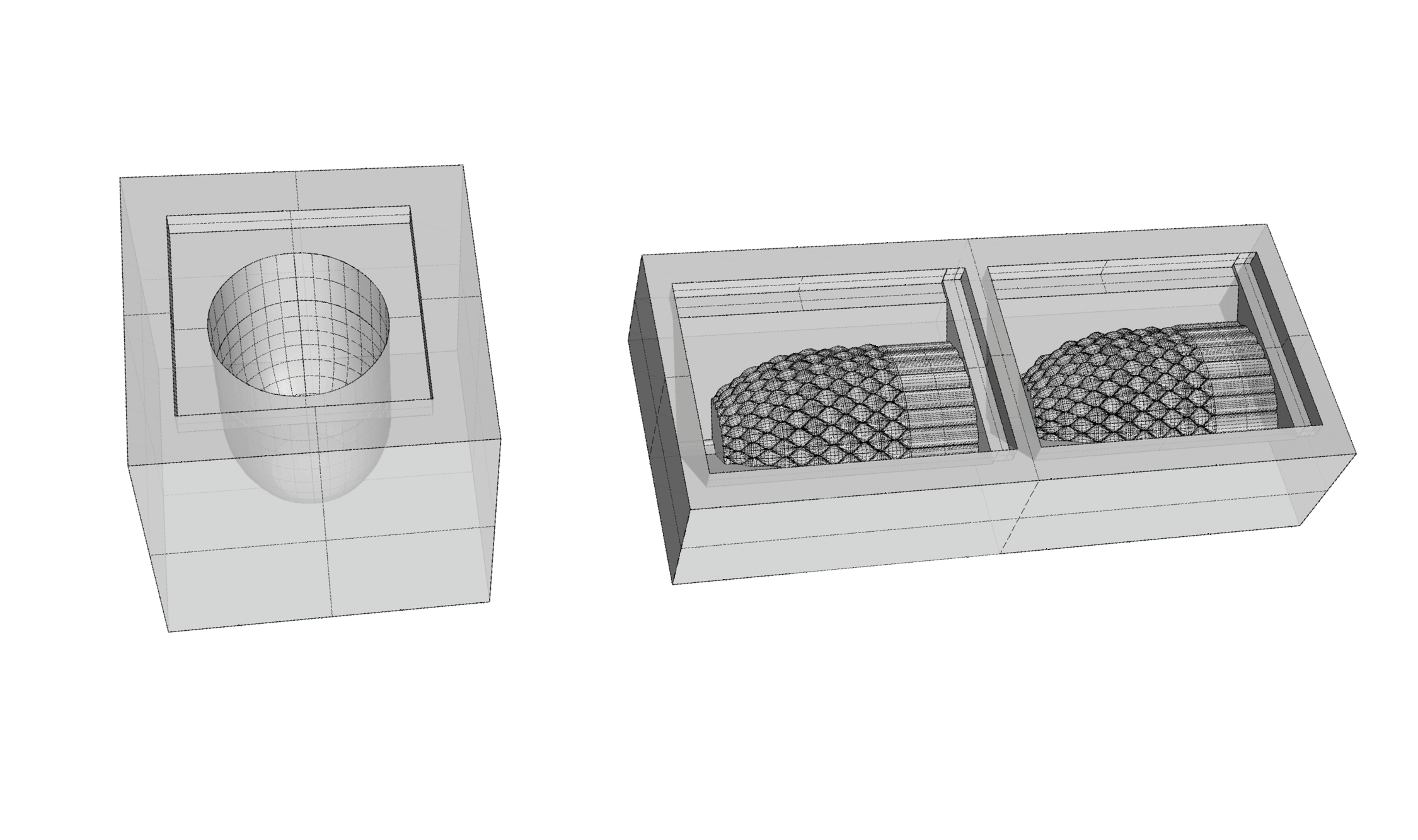

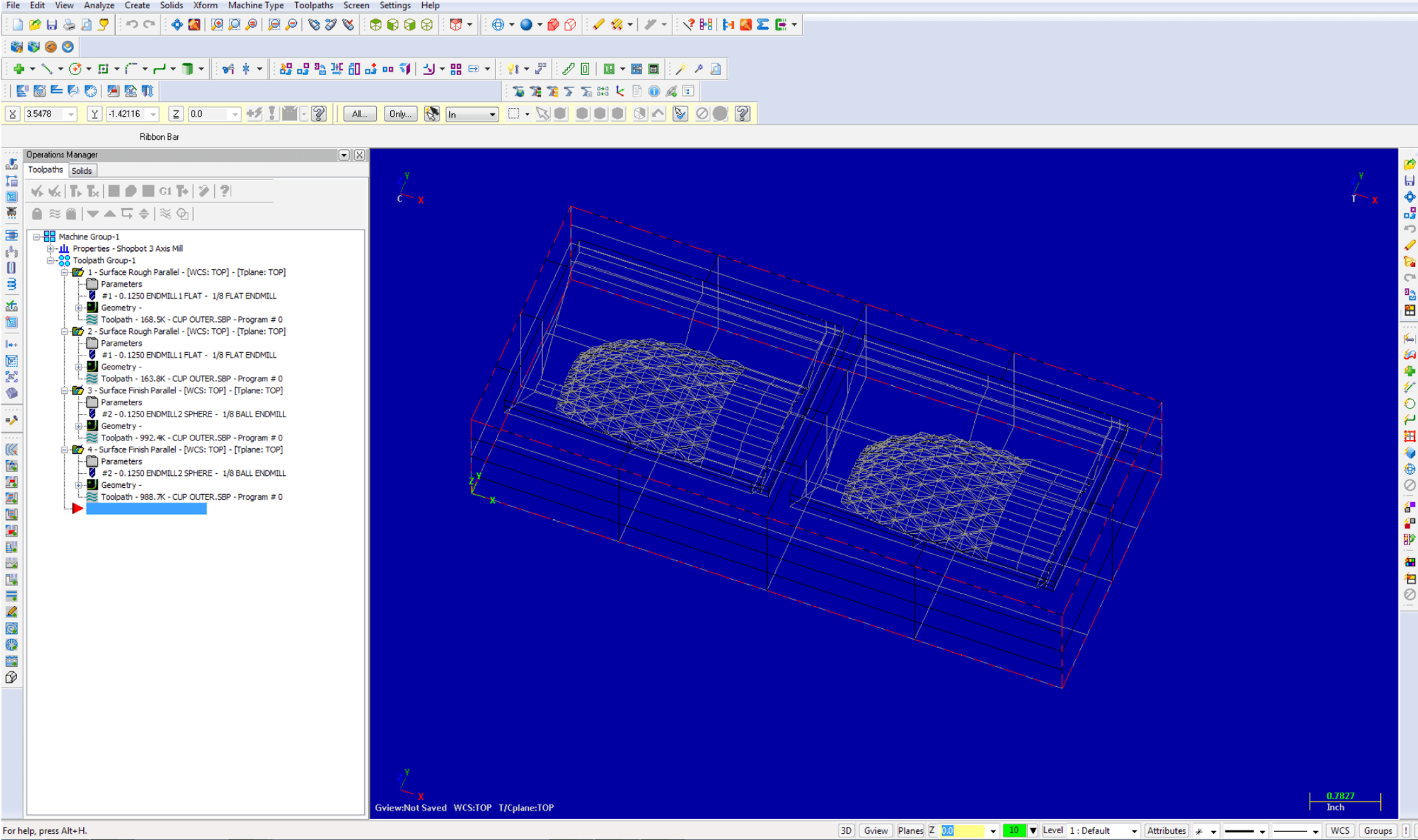

Then, I prepared the positive file to mill the wax on the shopbot

Adjusting the file in mastercam_One rough cut and a final smooth cut

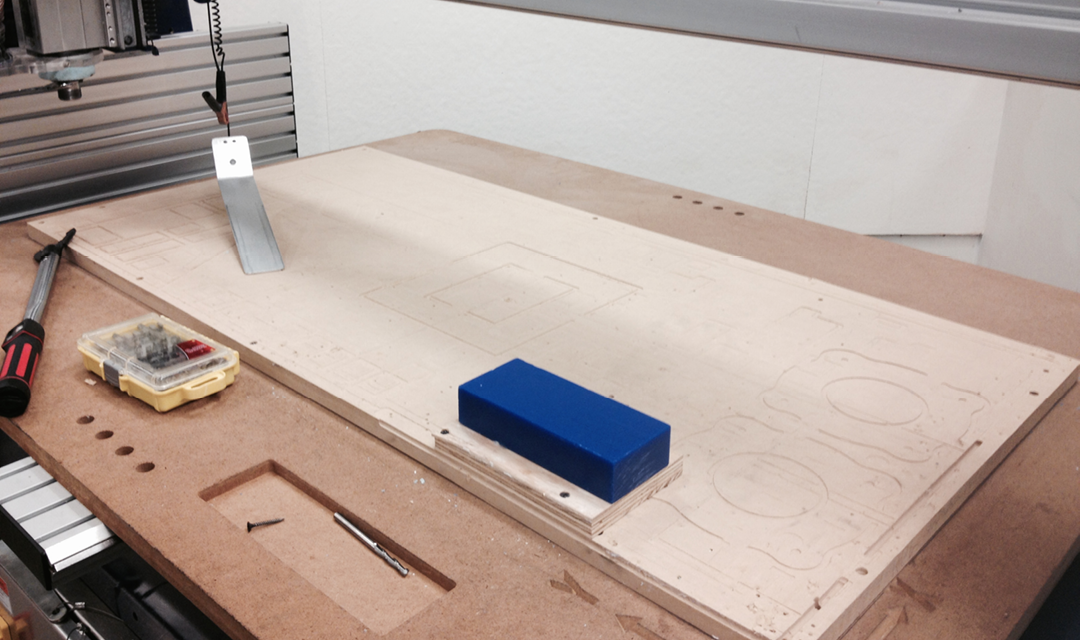

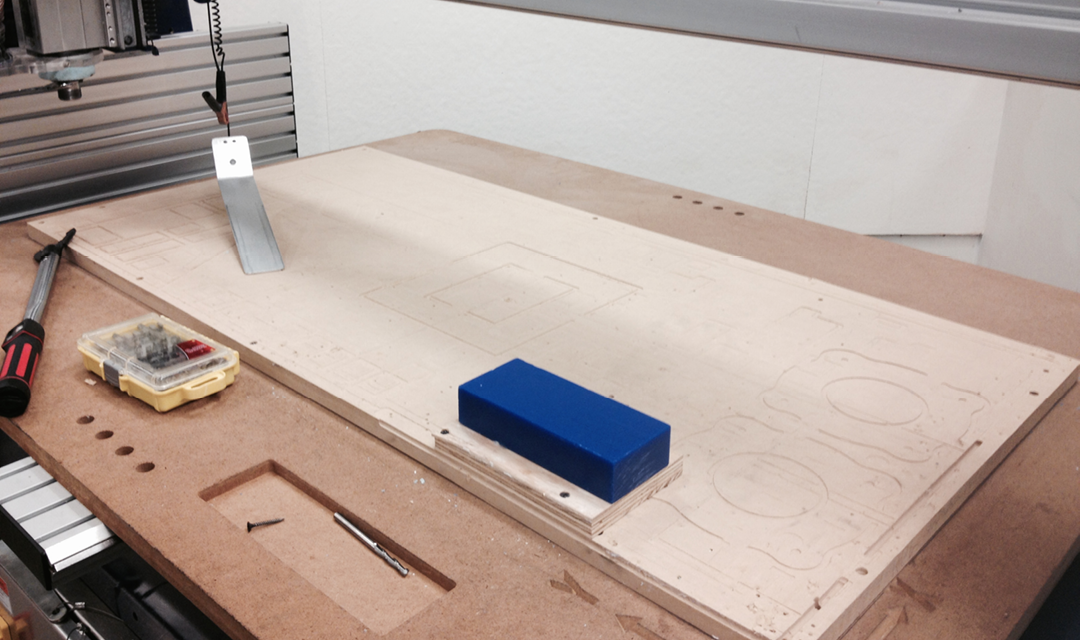

So, everything was ready for the milling. But.... due to some scheduling problems and long milling time on the shopbot, I was unable to mill the wax. Plan B was needed...

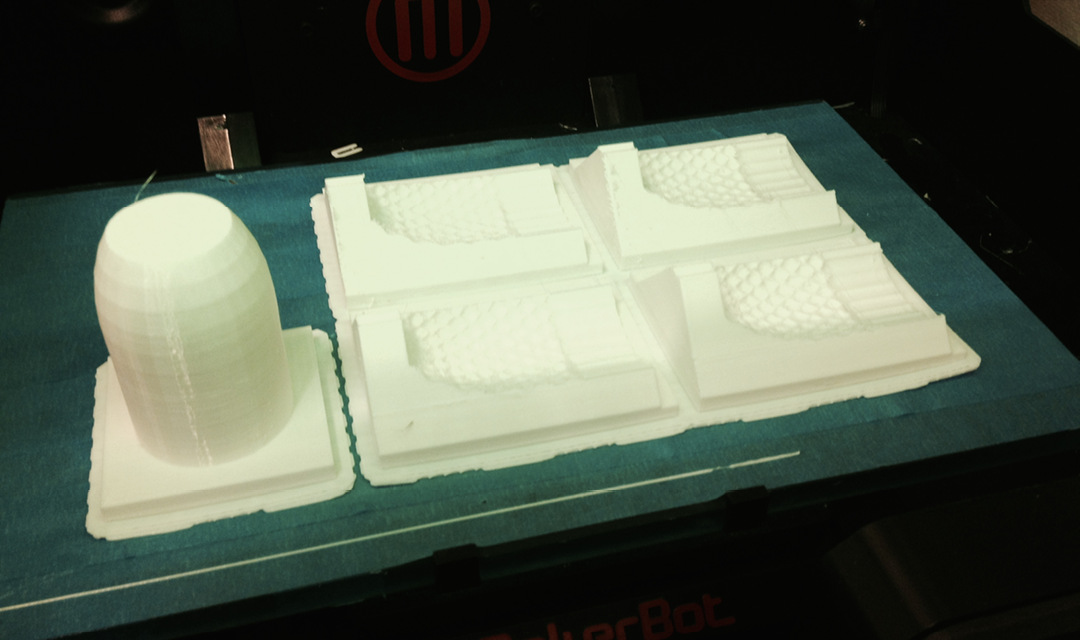

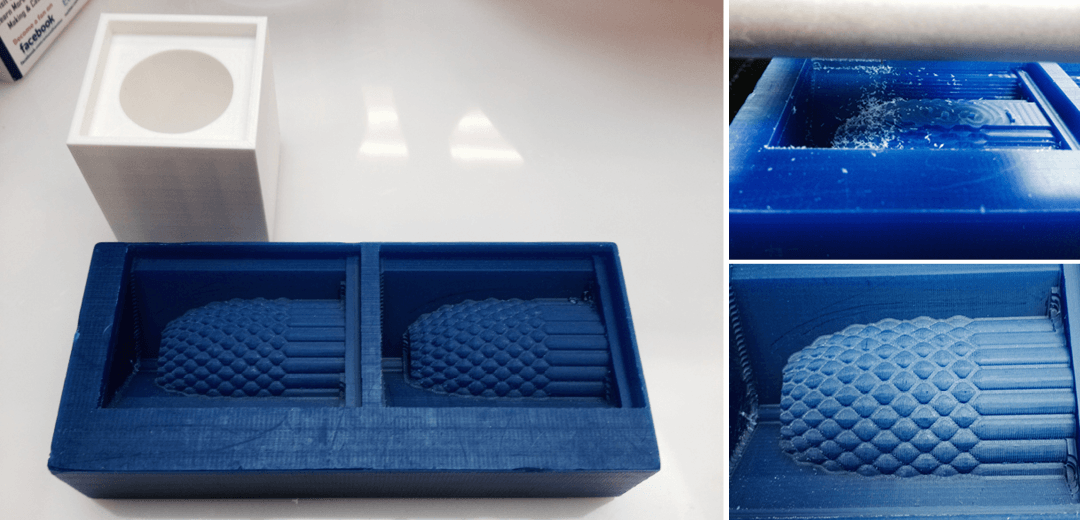

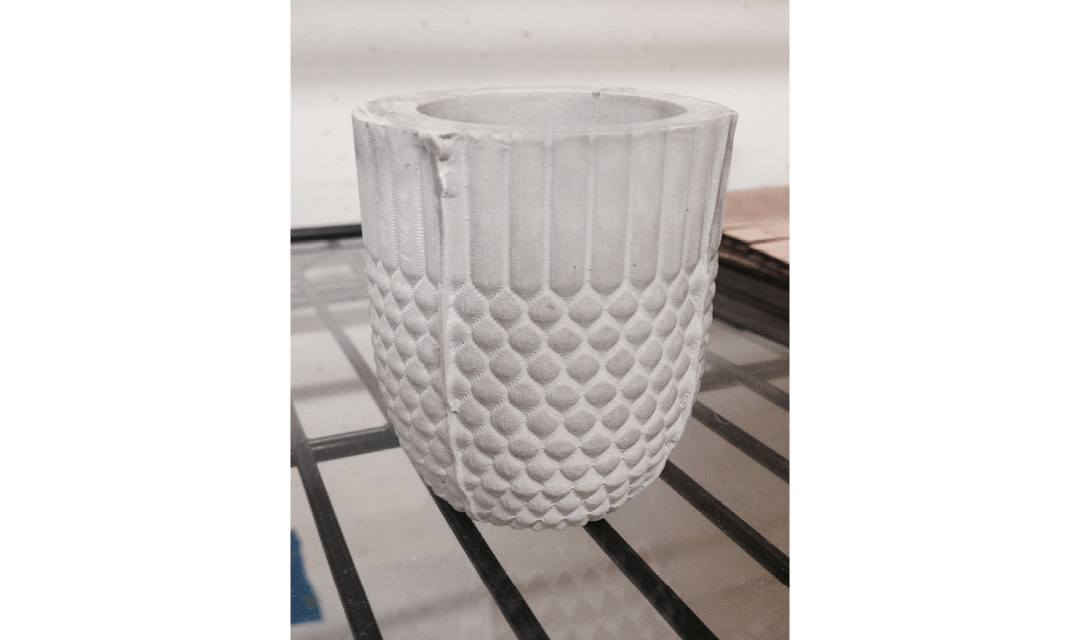

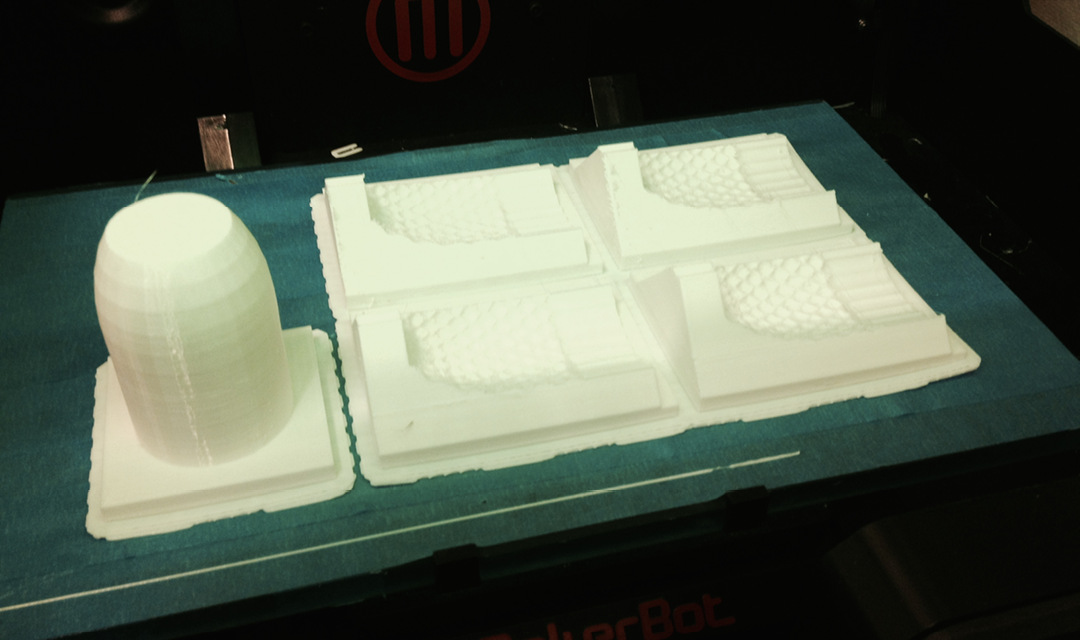

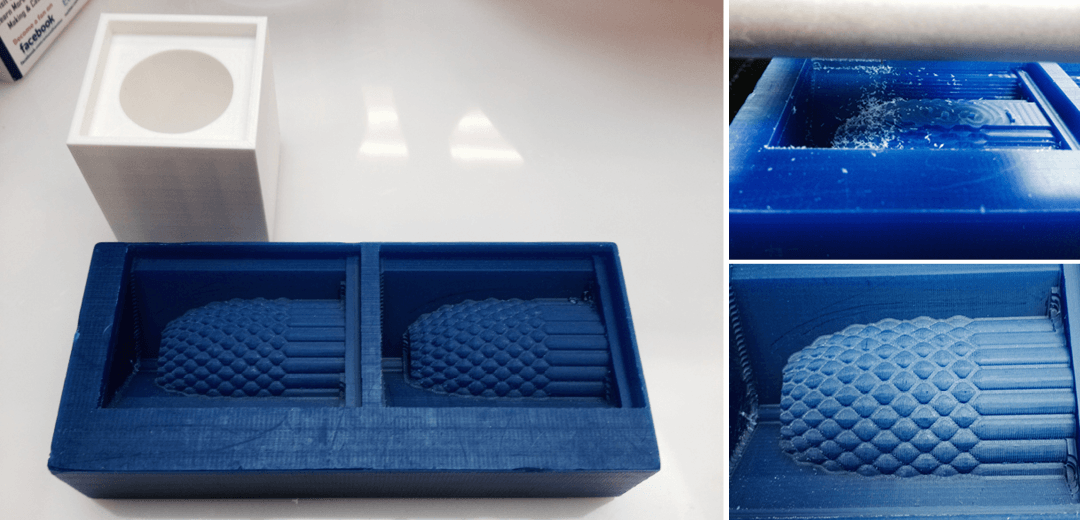

Plan B_3d printing the negetive, hoping I could use it for casting.

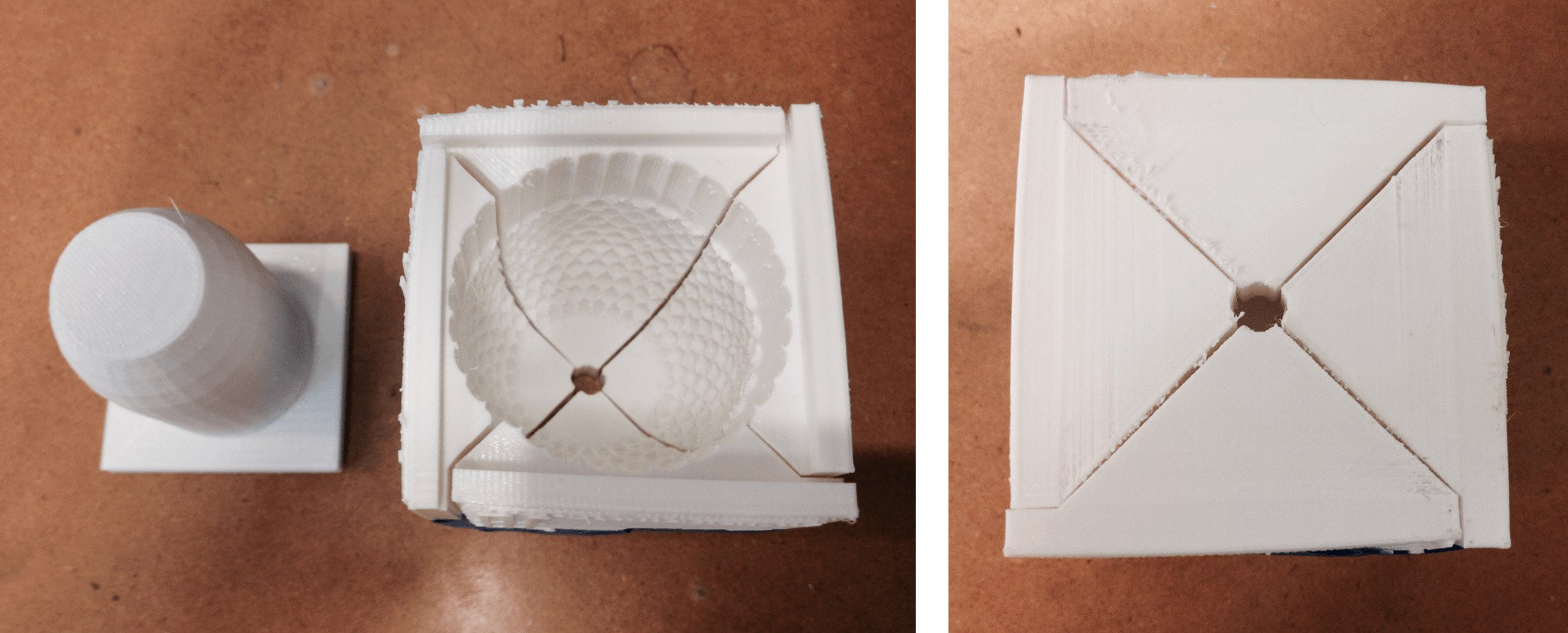

3D print result_Waiting to be filled with Hydro-Stone...

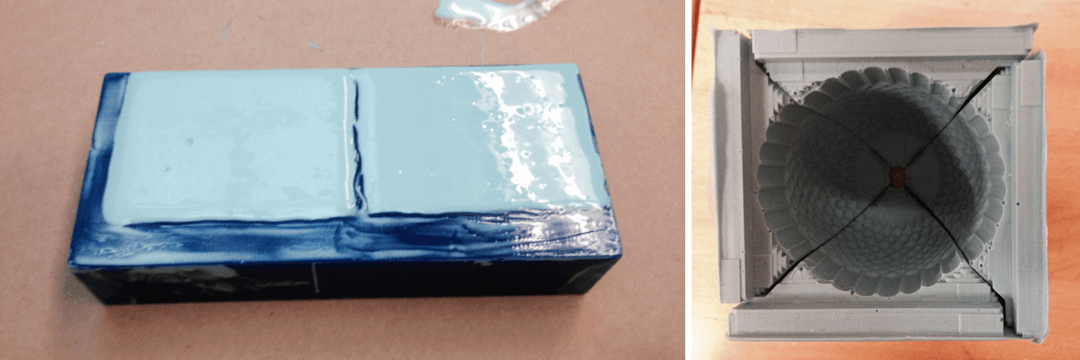

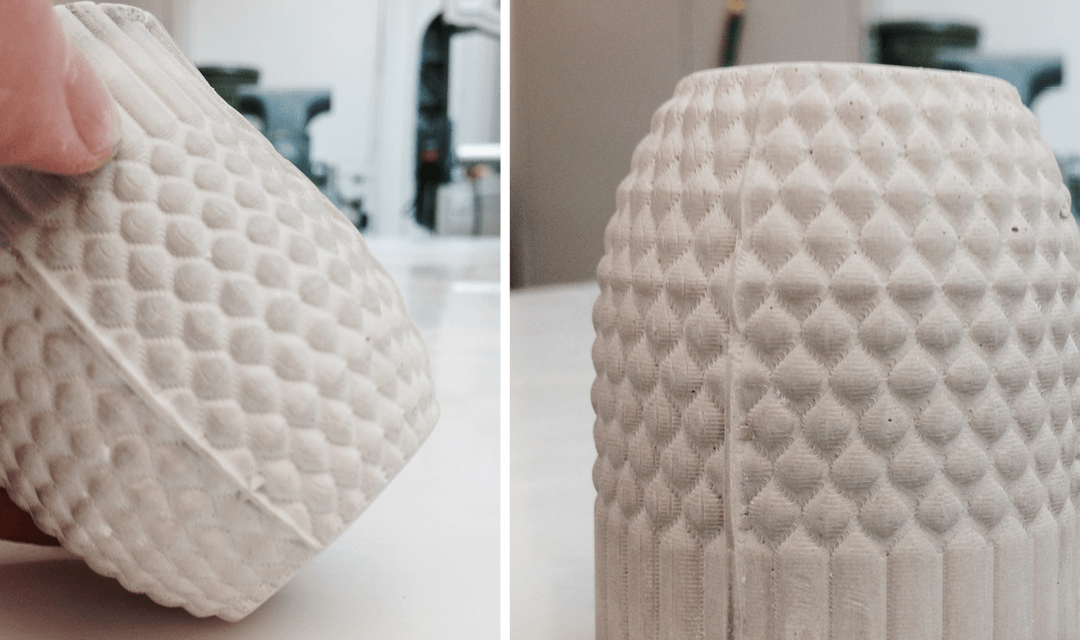

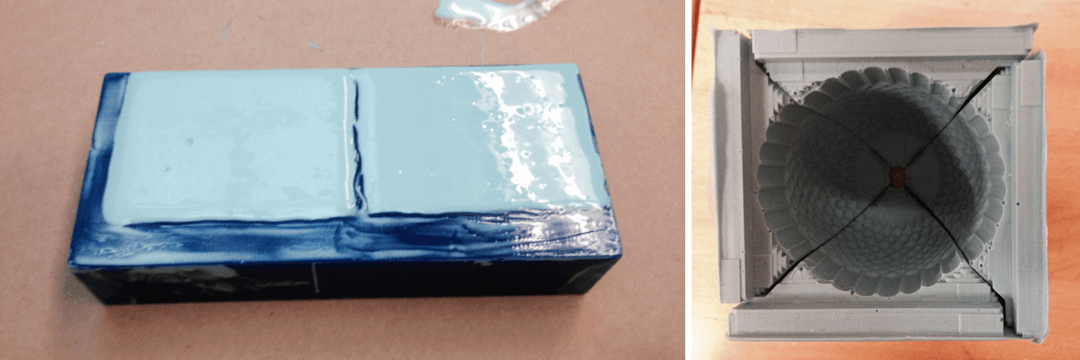

An Update_I didn’t like the result of the 3d printed mold - the texture was full of tiny 'hairs' (leftovers from the makerbot material) which I was unable to remove. I decided to mill the wax in the modela and prepare an oomoo mold.

The oomoo mold

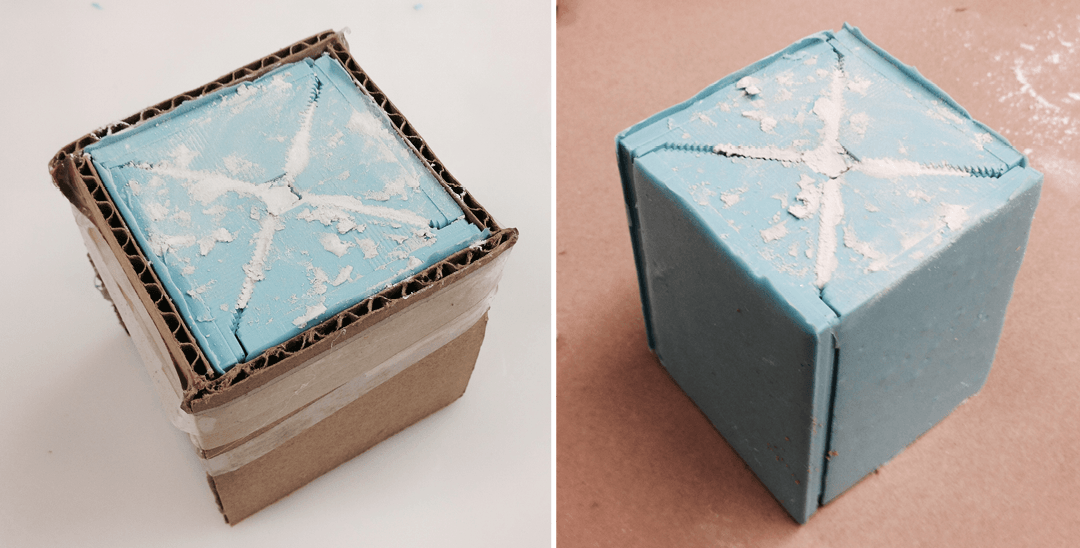

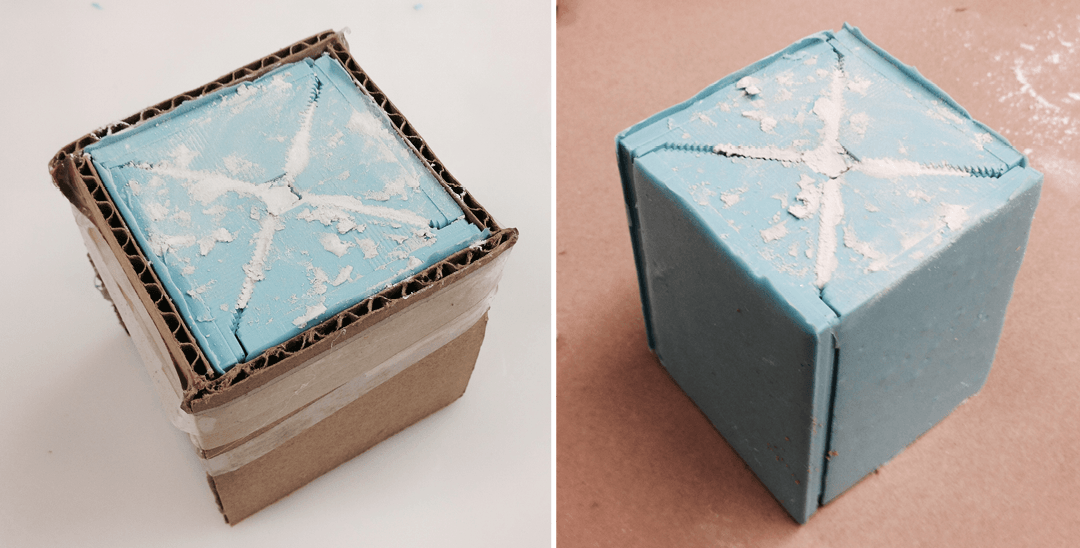

Hydro-Stone casted into the mold

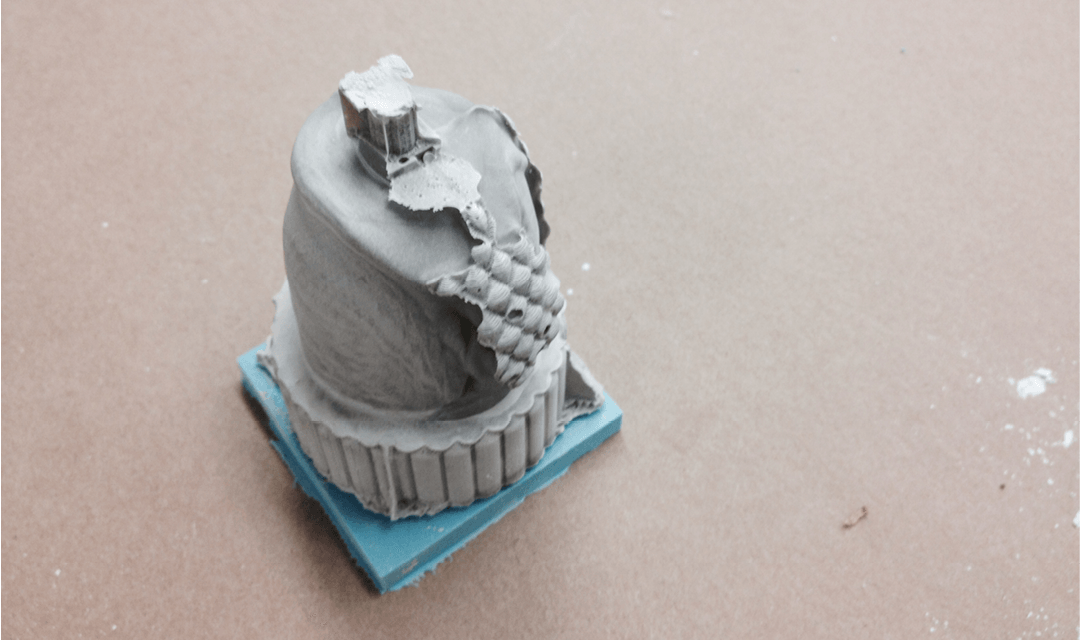

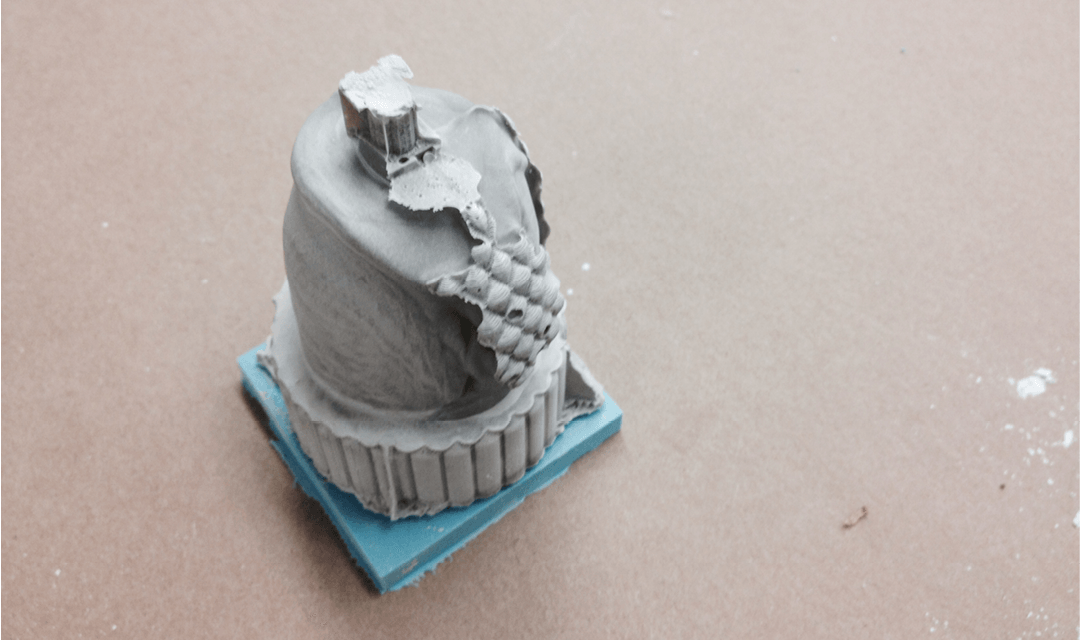

Attempt #1_a glorious failure... I probably didn’t pour enough Hydro-Stone into the mold + I should have vibrate the mold while pouring so that the Hydro-Stone will reach every part of it.

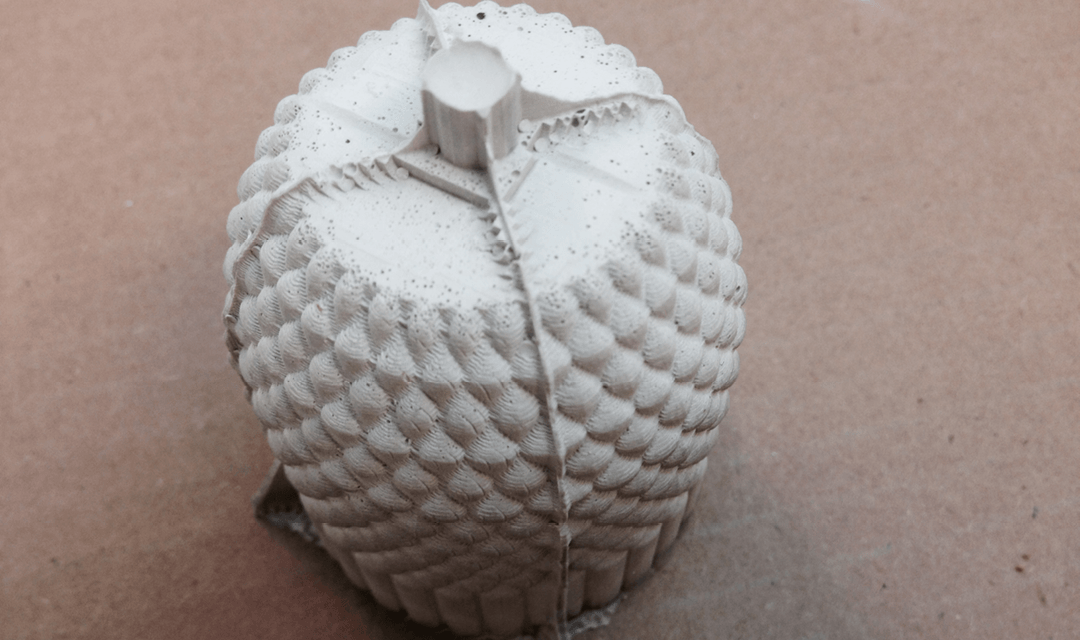

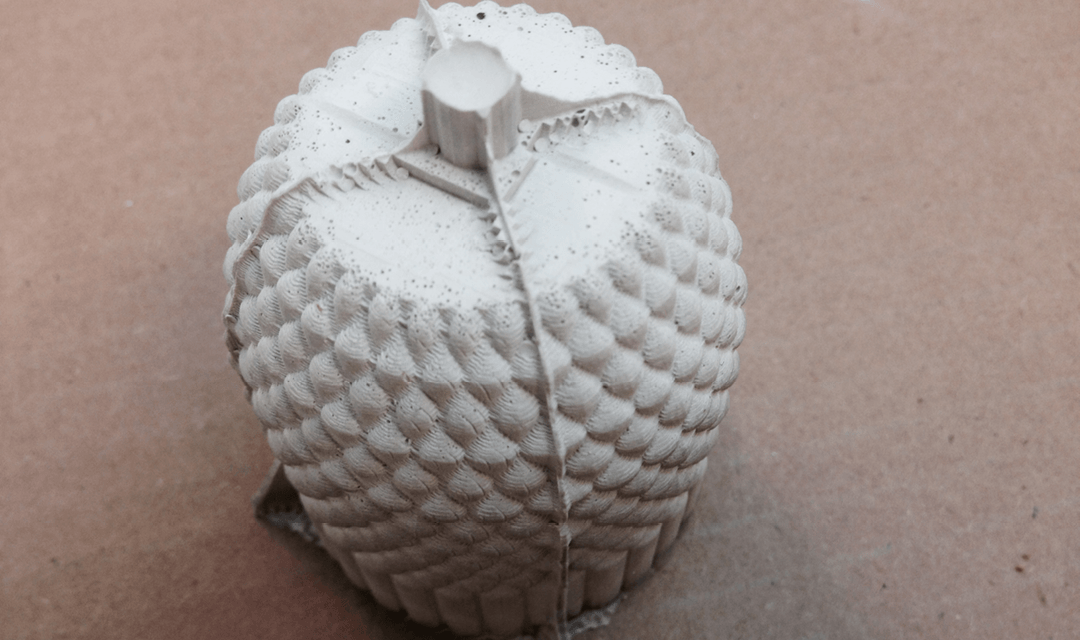

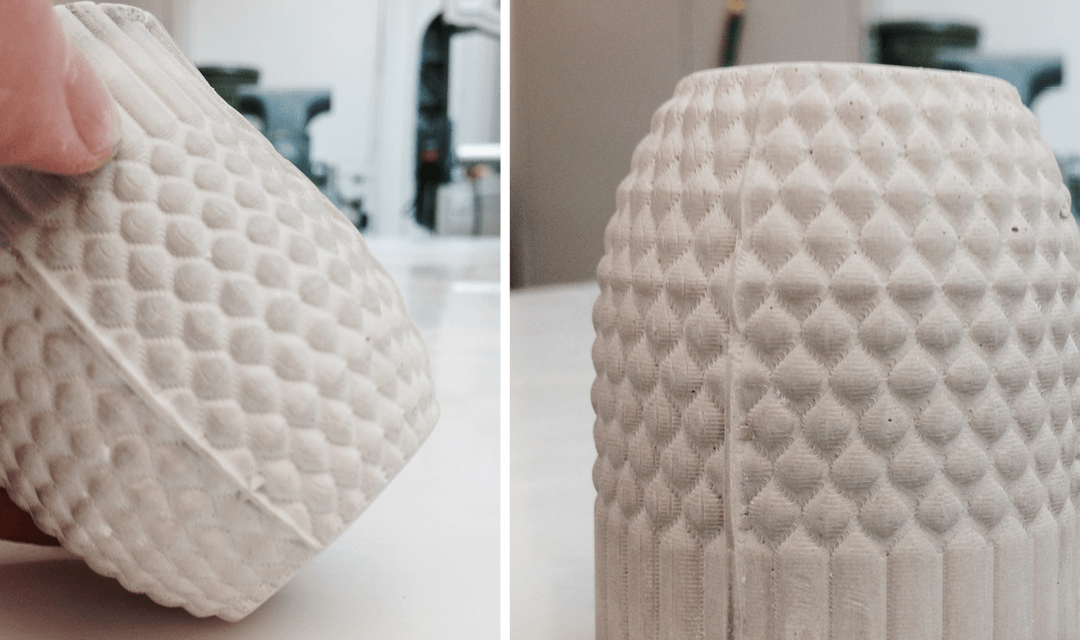

attempt #2_much better!

After a little bit of sanding

For this week assignment I wanted to mold and cast an object with a 3d pattern. I downloaded a weaving definition for grasshopper, and played with it a little bit. Then I wanted to be able to apply that pattern on any 3d surface, so I extracted a basic tile from the pattern, and wrote a grasshopper definition that enables to morph the tile on any kind of surface.

For this week assignment I wanted to mold and cast an object with a 3d pattern. I downloaded a weaving definition for grasshopper, and played with it a little bit. Then I wanted to be able to apply that pattern on any 3d surface, so I extracted a basic tile from the pattern, and wrote a grasshopper definition that enables to morph the tile on any kind of surface.