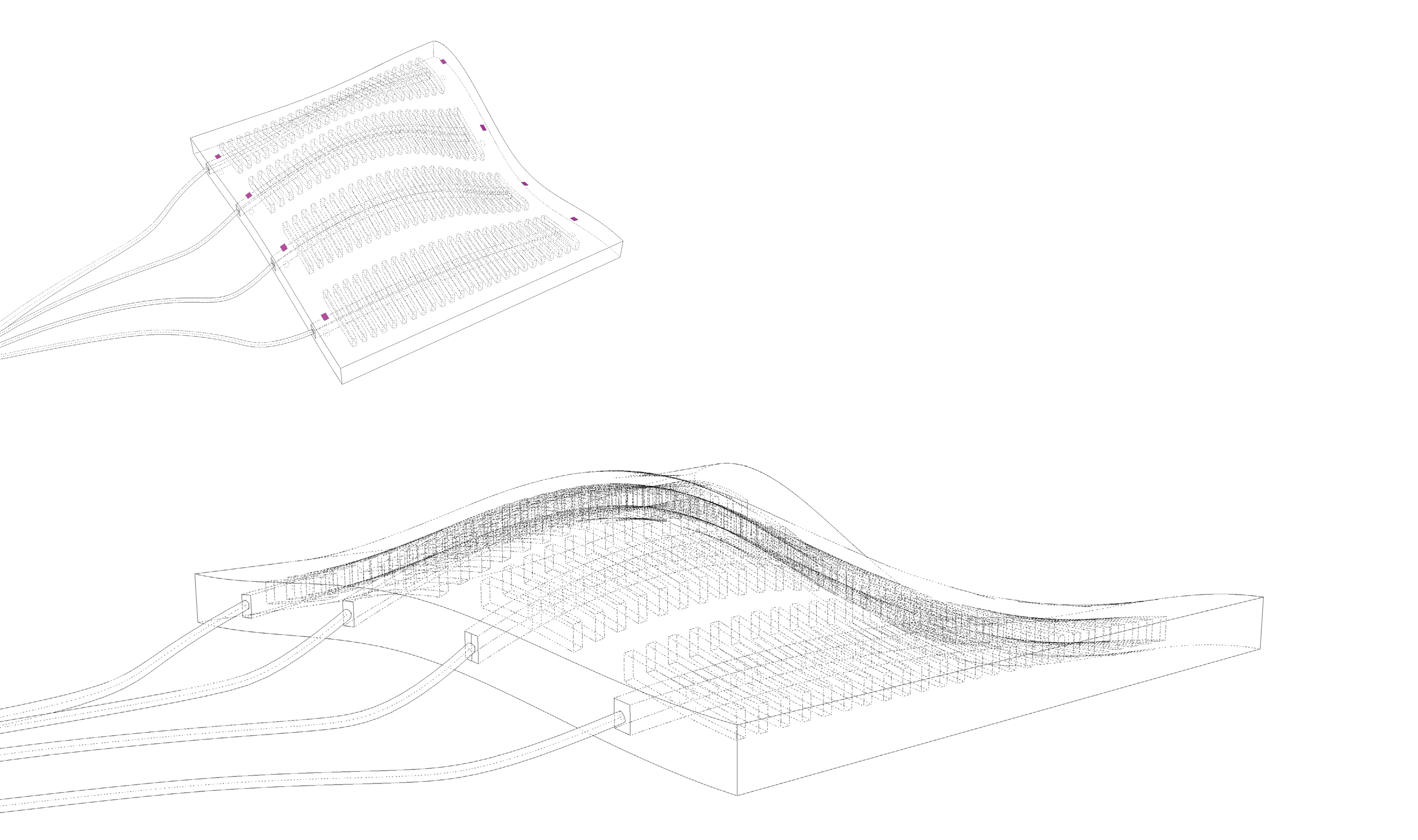

An Inflatable surface, made from Soft Pneumatic Actuators.

The technique is similar to the one being used in the Harvard soft robot project (Molding and casting of rubber). In order to learn more about the technique, I also found these 2 tutorials very useful:1 , 2

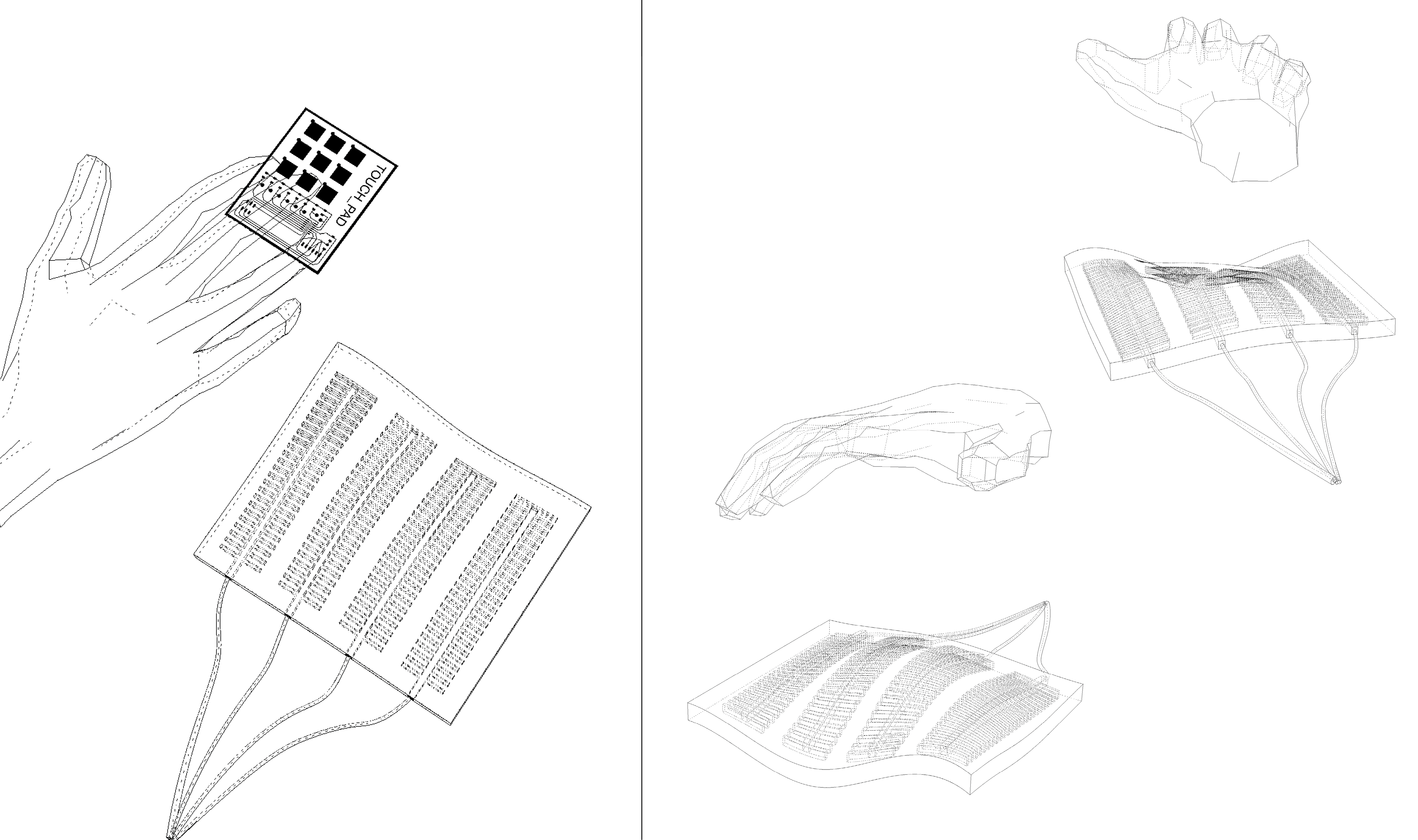

The surface will be controlled by hand gestures or by the touch_pad I made for input_devices week

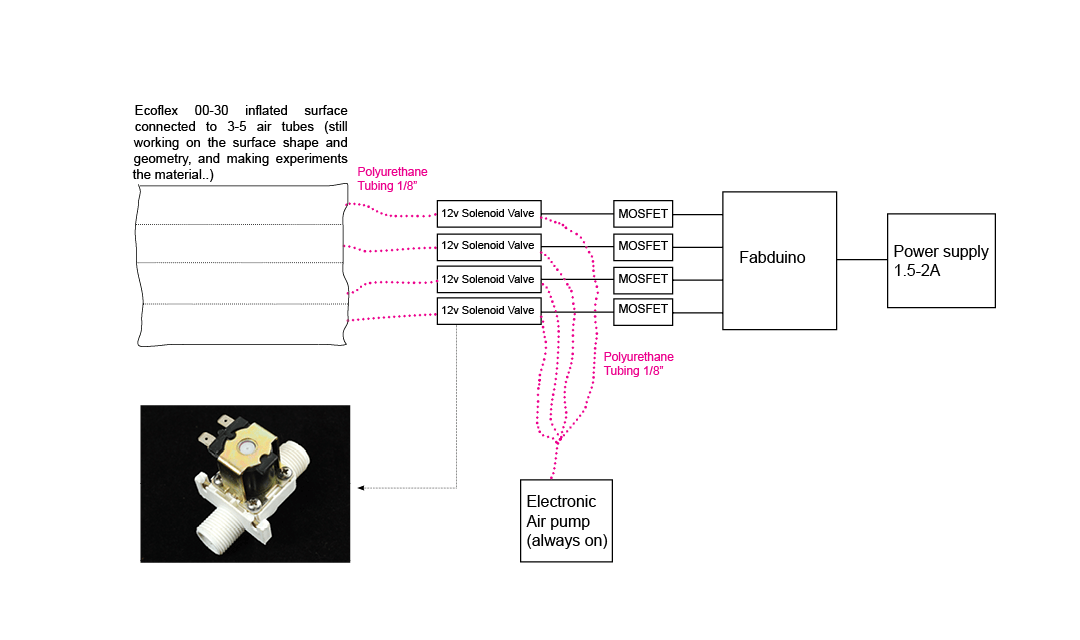

Electronics Scheme

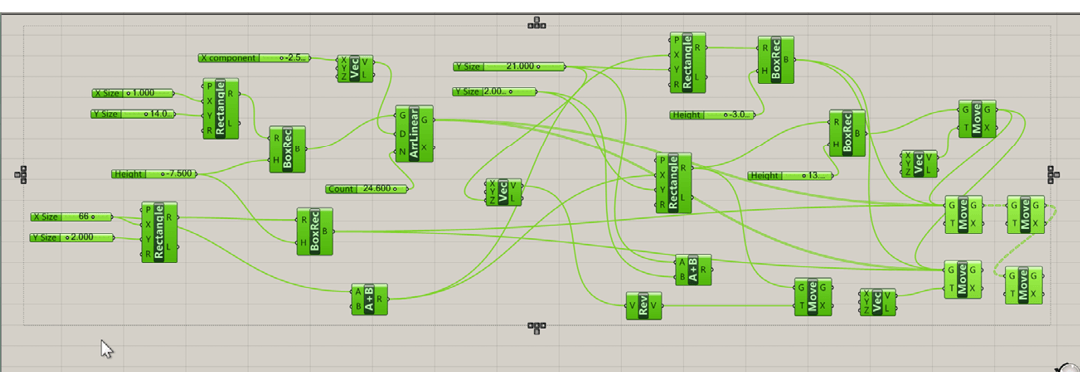

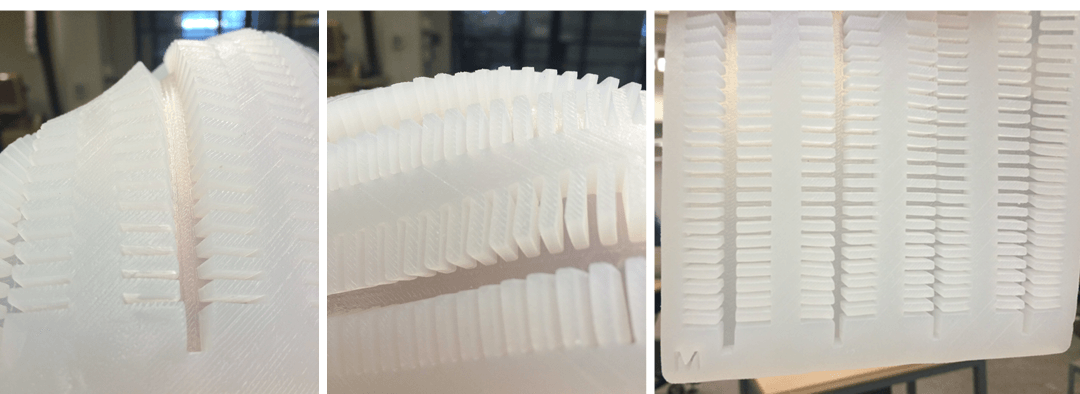

Building the mold in grasshopper. The sliders allow to modify the air chambers properties.

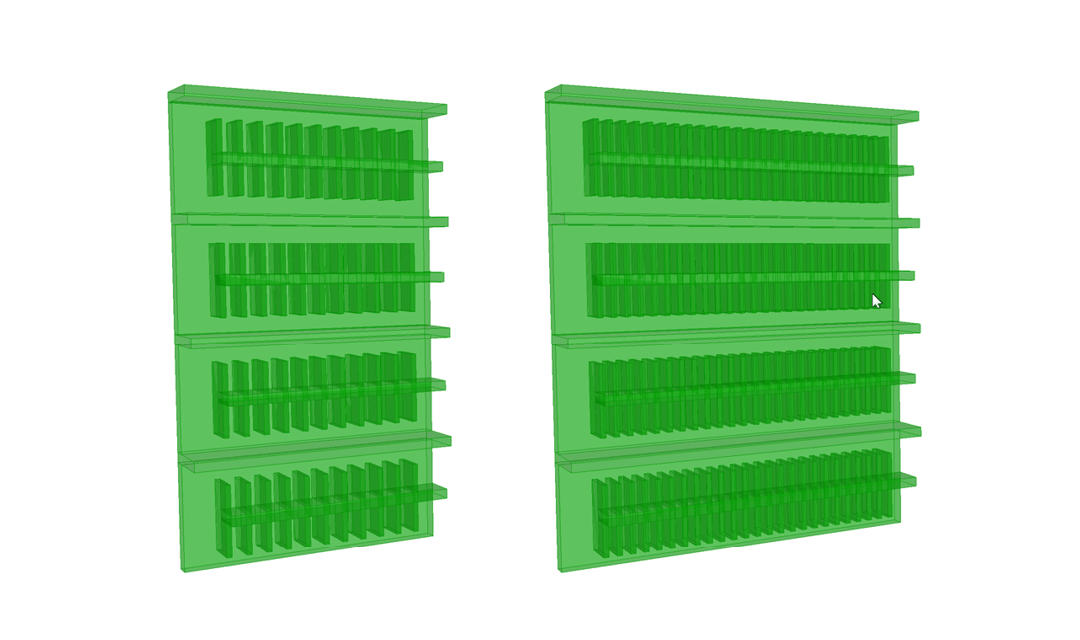

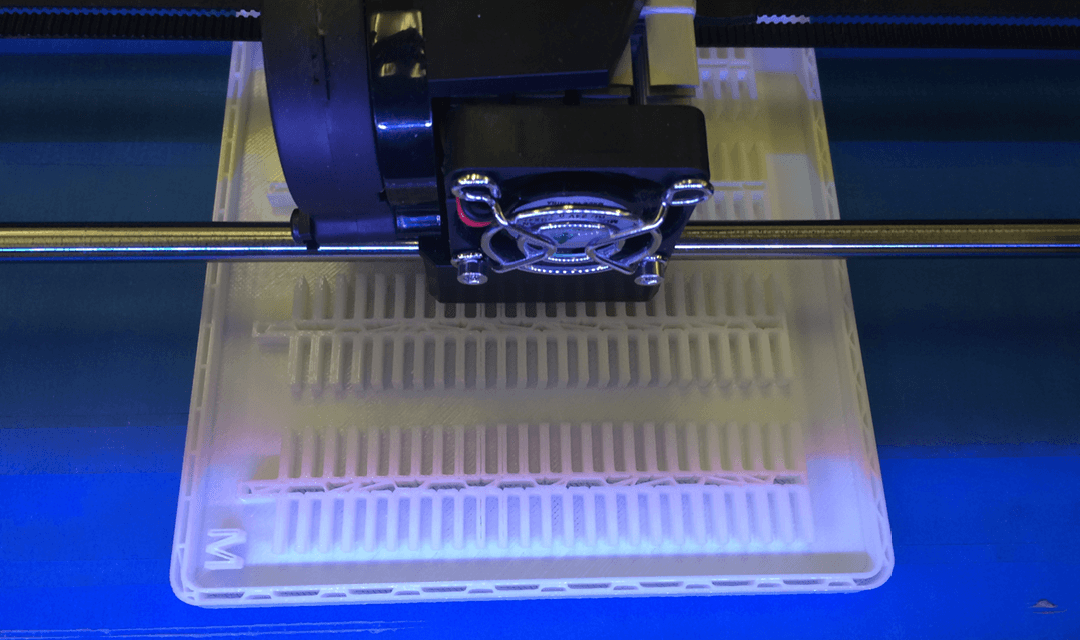

3d printing the mold

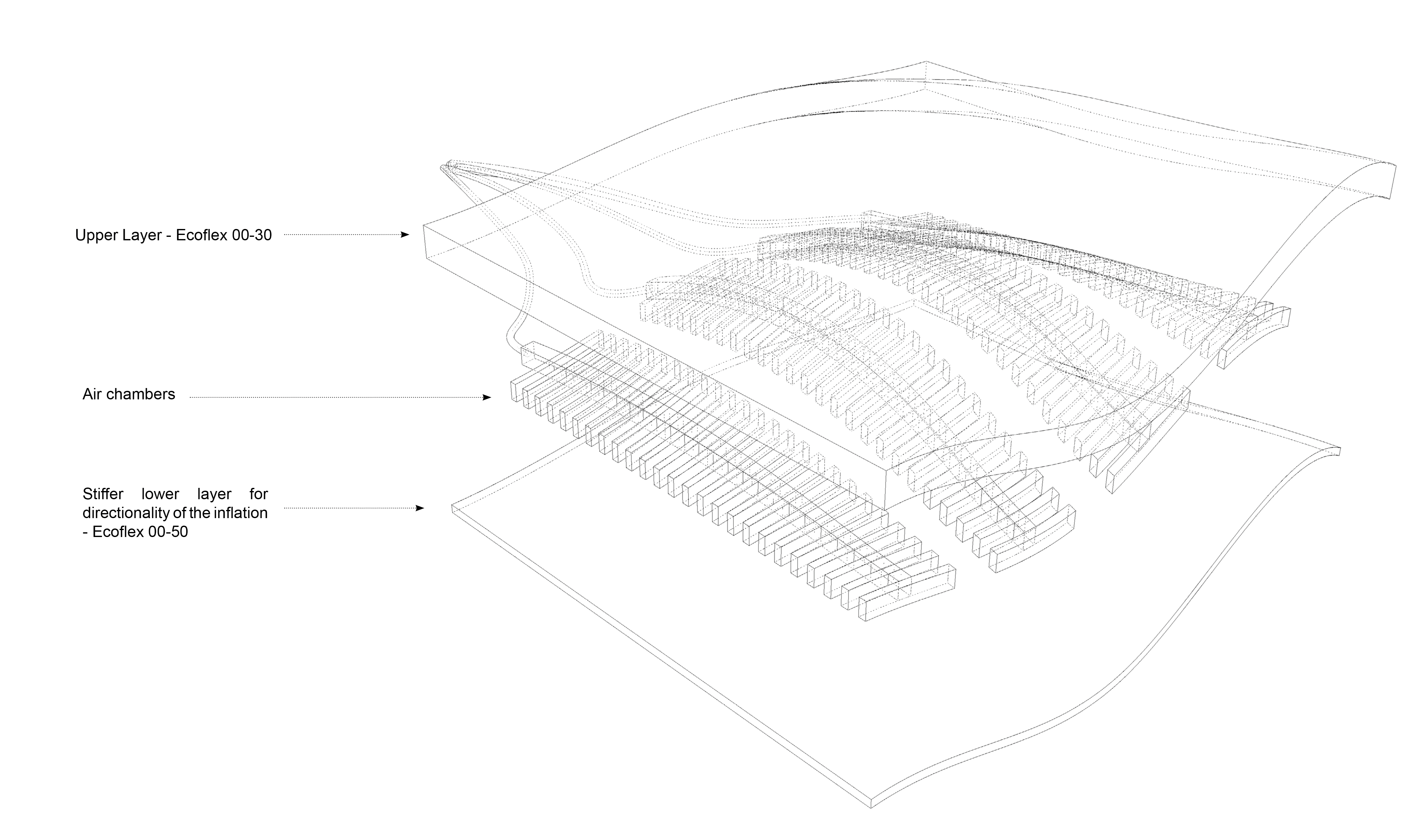

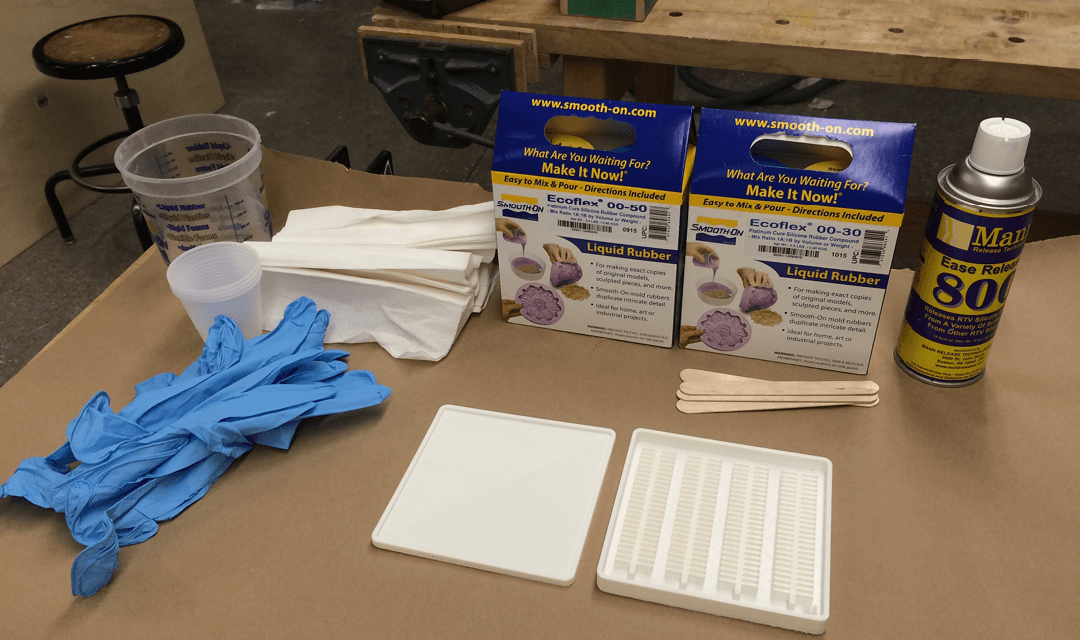

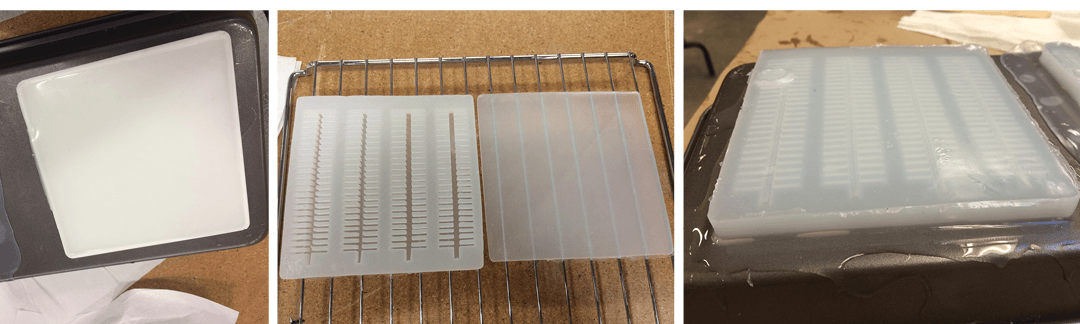

Preparing all the materials for casting the Ecoflex. Ecoflex 00-30 for the top mold and ecoflex 00-50 for the bottom mold.

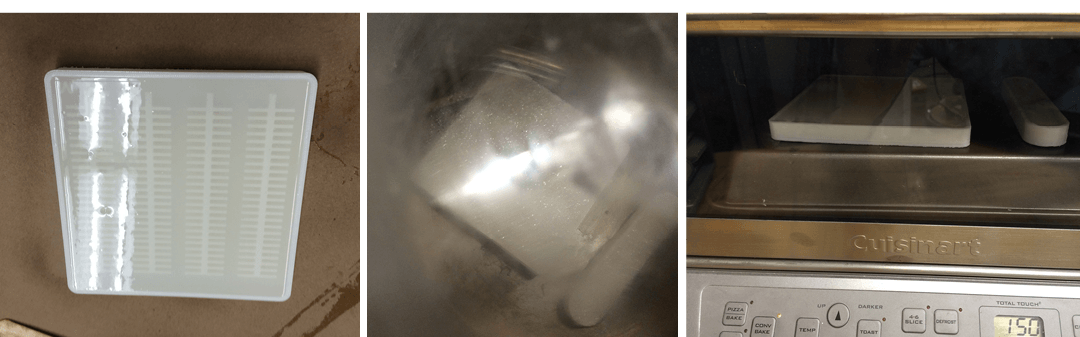

Casting silicon _ de-gassing_ curing in the oven for 10 minutes at 150F (Instead of 4 hours cure time for Ecoflex 00-30 and 3 hours cure time for Ecoflex 00-50). Ecoflex 00-30 pot life is 45 minutes, so you can take it easy...

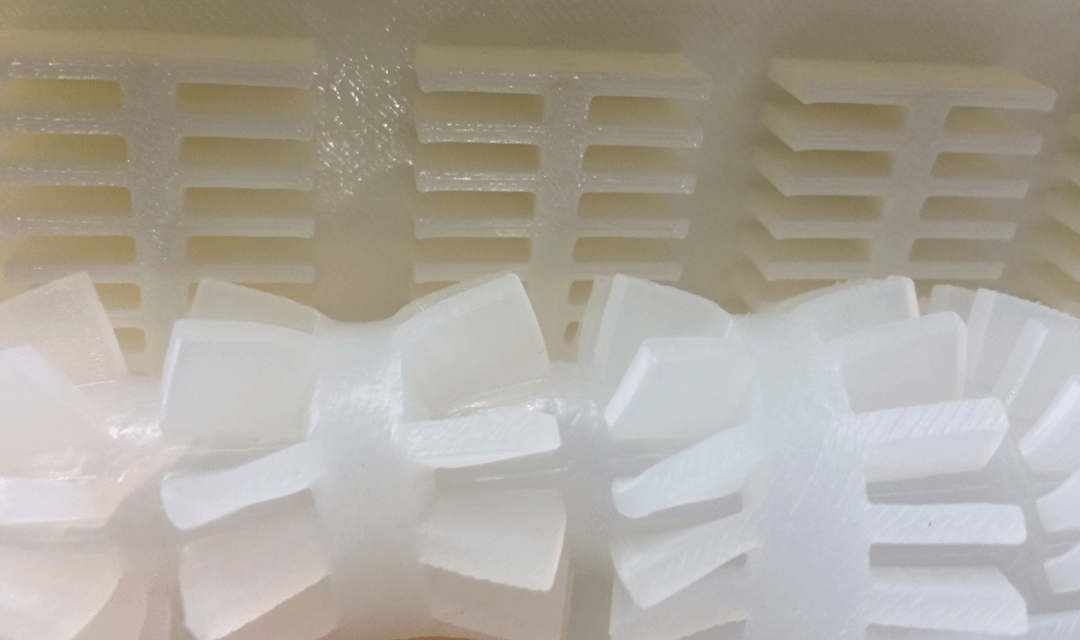

Removing the silicone from the mold. I used a lot of mold release before casting, otherwise the small chambers get stuck in the mold.

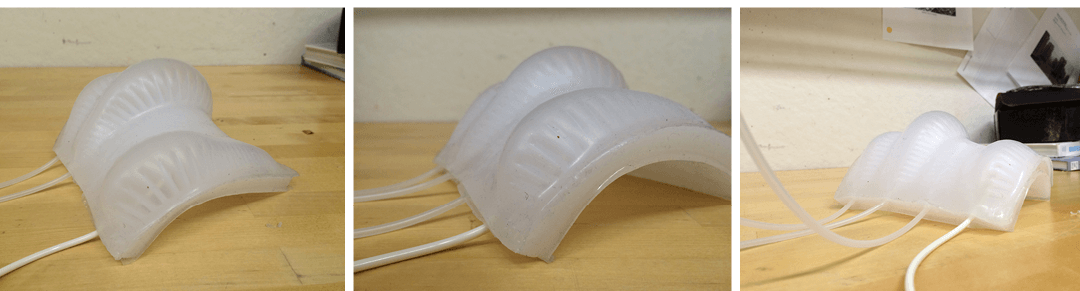

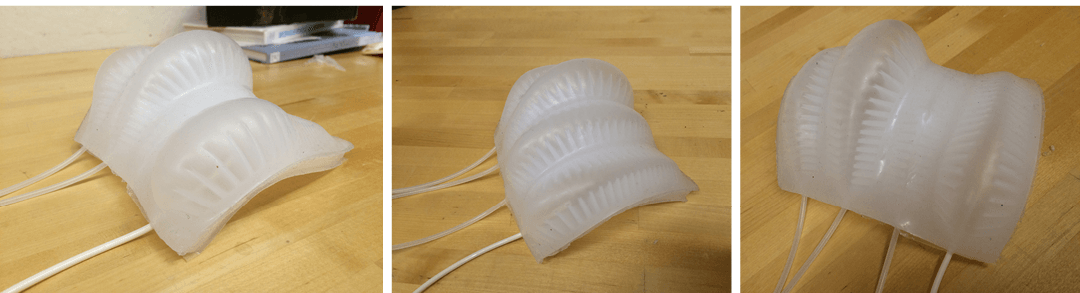

Top and bottom parts of the surface being glued together (after curing) with another layer of Ecoflex.

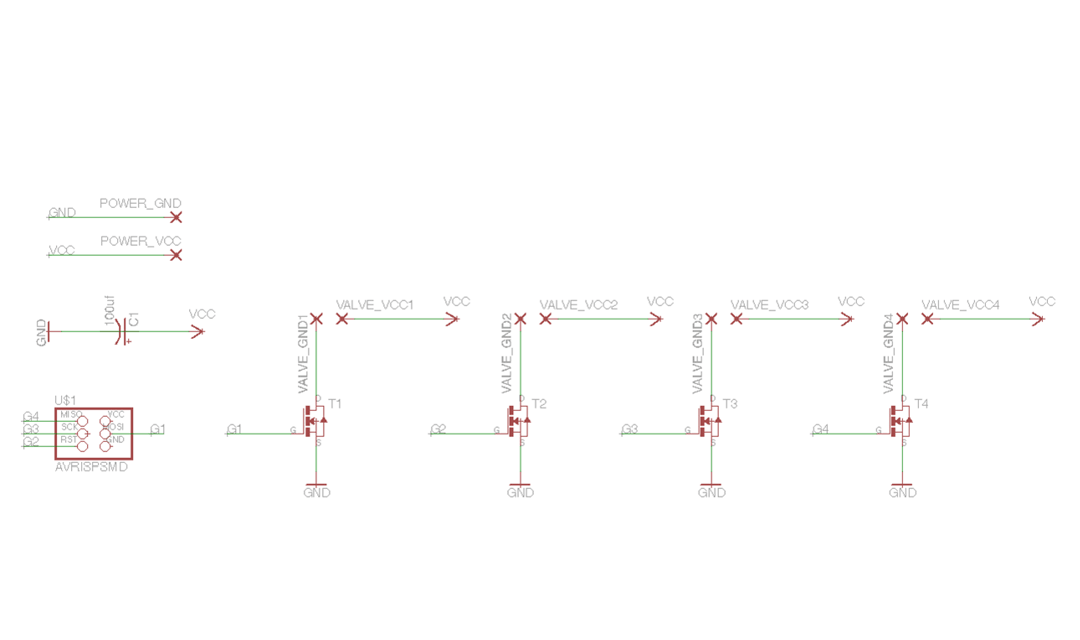

While preparing and testing the silicon surface, I started working on the schematic in eagle. A MOSFET circuit that will be attached to the 4 solenoid valves. The plan was to power the microcontroller (at the fabduino board) through the computer, and to power the MOSFETS through a 12V power supply, using common ground. I added a big capacitor (100uf) across the mosfets power supply.

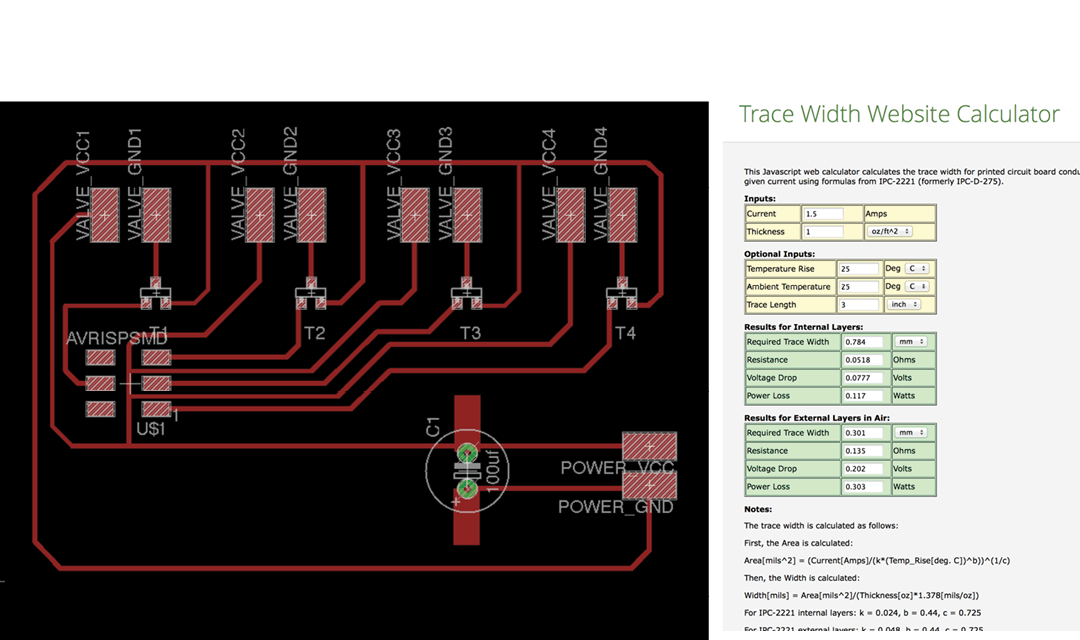

Tracing the board. In order to determine the traces thickness, I used the above calculator (sent by Jeff). Surprisingly I didn’t need to use thicker traces then the one we usually use. I made them a little bit thicker the usual, just in case.

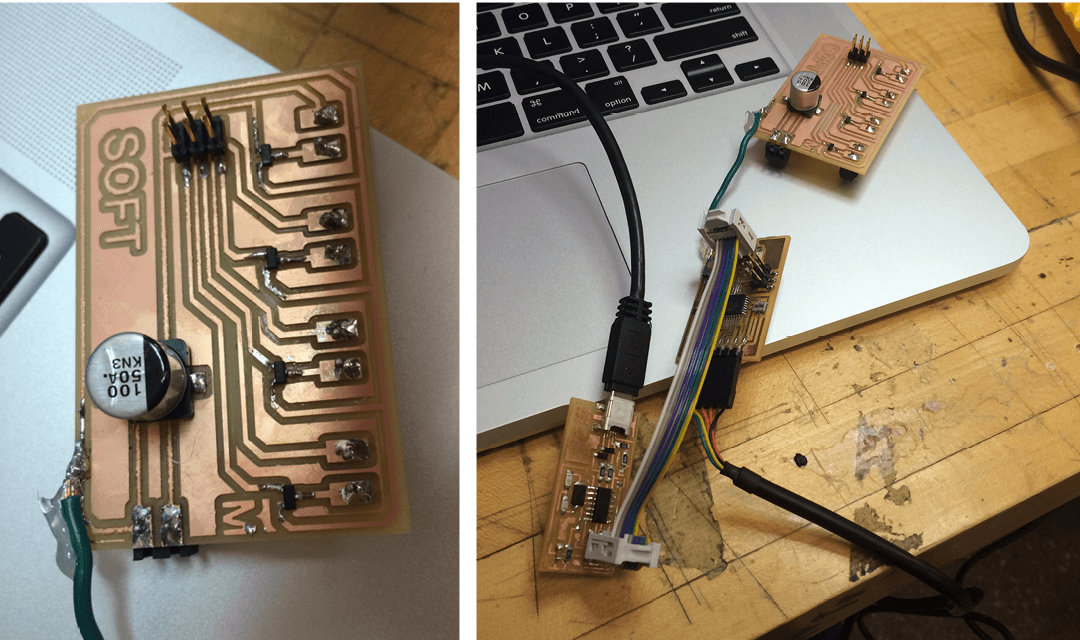

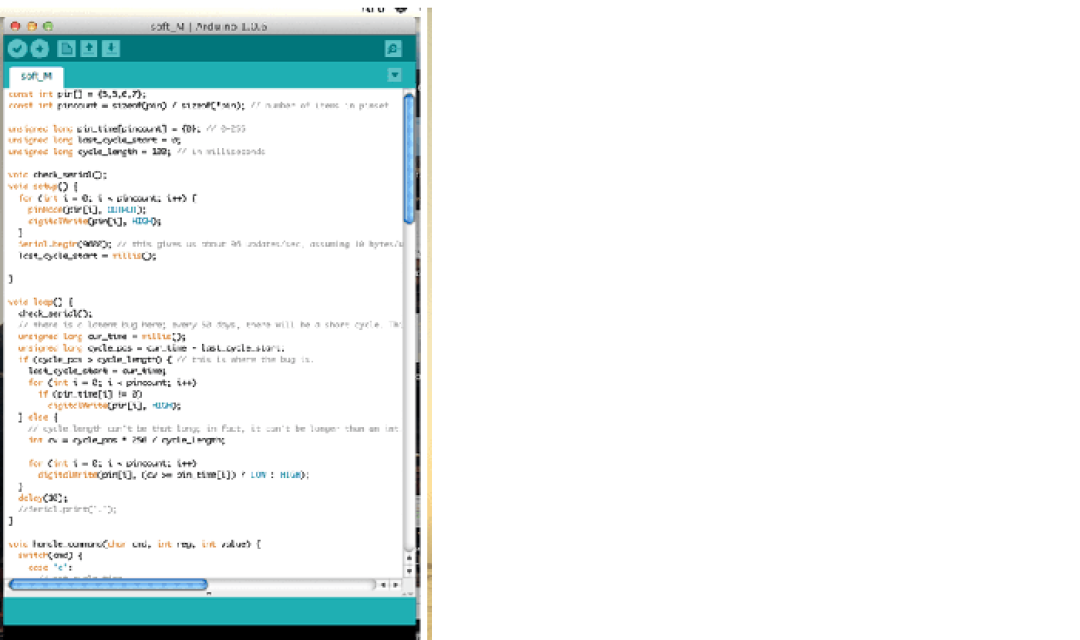

Trying to program the board + fabduino with the fabISP on Arduino (The green wire between the MOSFETS circuit and the fabduino is for common ground). I straggled a lot with that part... I kept getting error massages... The last one was that the programmer is not responding. I double checked the fabISP with other boards and it worked perfectly. I believe that there was some kind of problem with the fabduino.

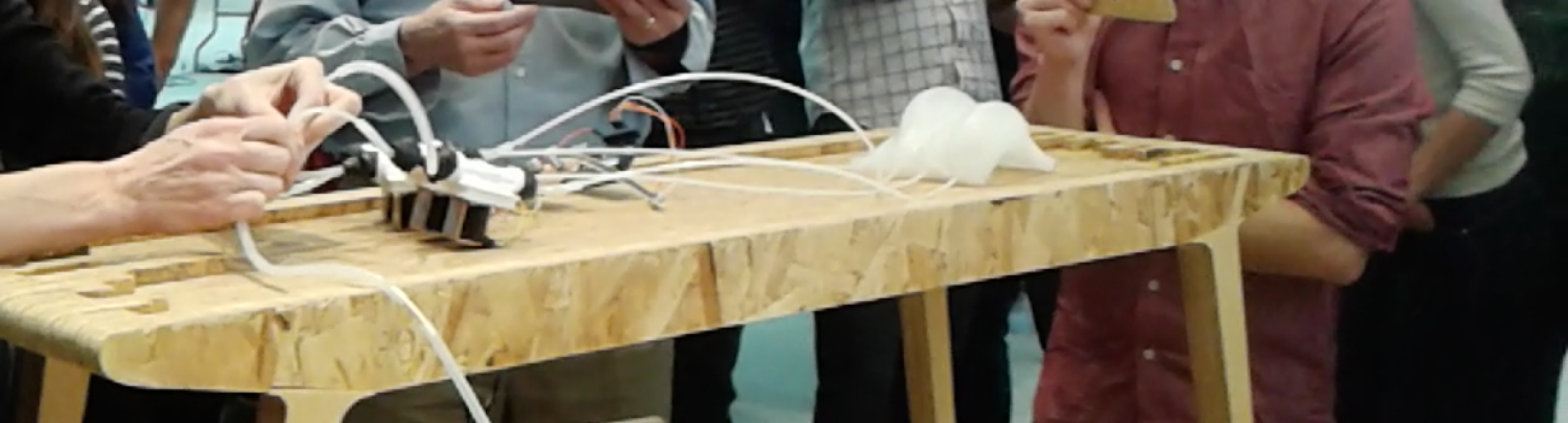

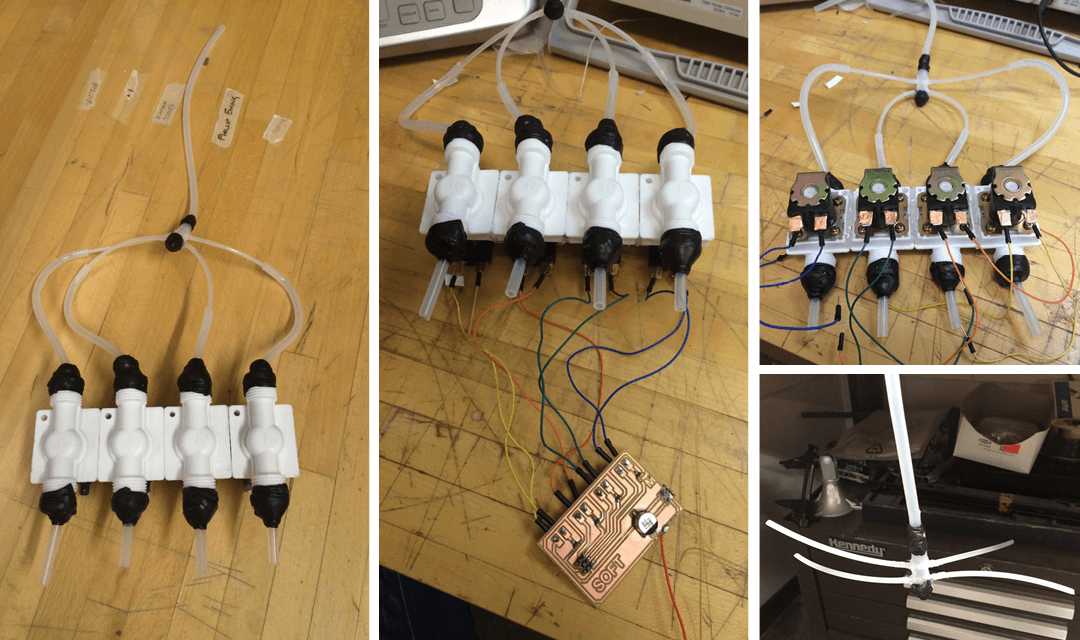

Preparing all the connection for the Solenoids (air and power).Because of size differences between the solenoids and the tubes I ordered, I hacked some DIY fittings using Black mastic sealing tape and stretchy silicone tubes.

On my final attempt to program the board, I used an arduino board with my MOSFETS circuit. I was able to program, but right now the solenoids are only able to stay open, and they all open at ones, so I'm unable to control them separately and create a more active movement in the surface. I really hope to be able to solve these issues soon...