For my press-fit project I chose to create an Eiffel Tower replica.

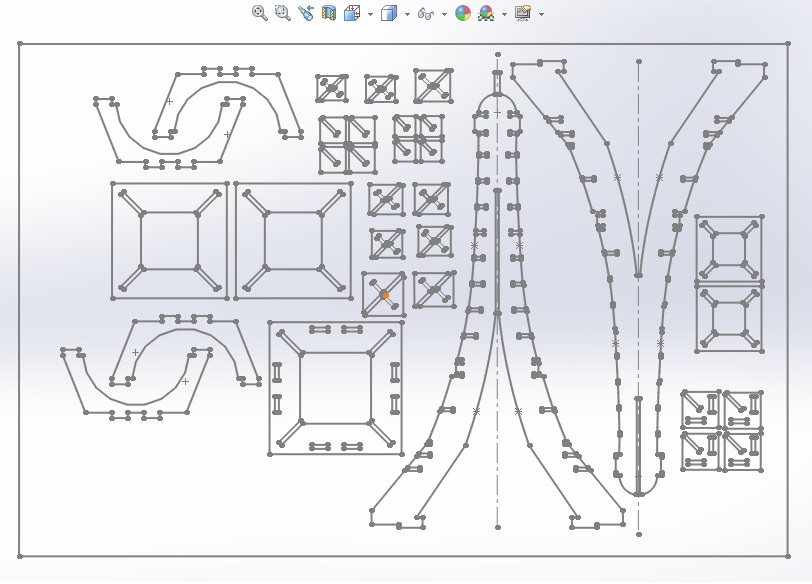

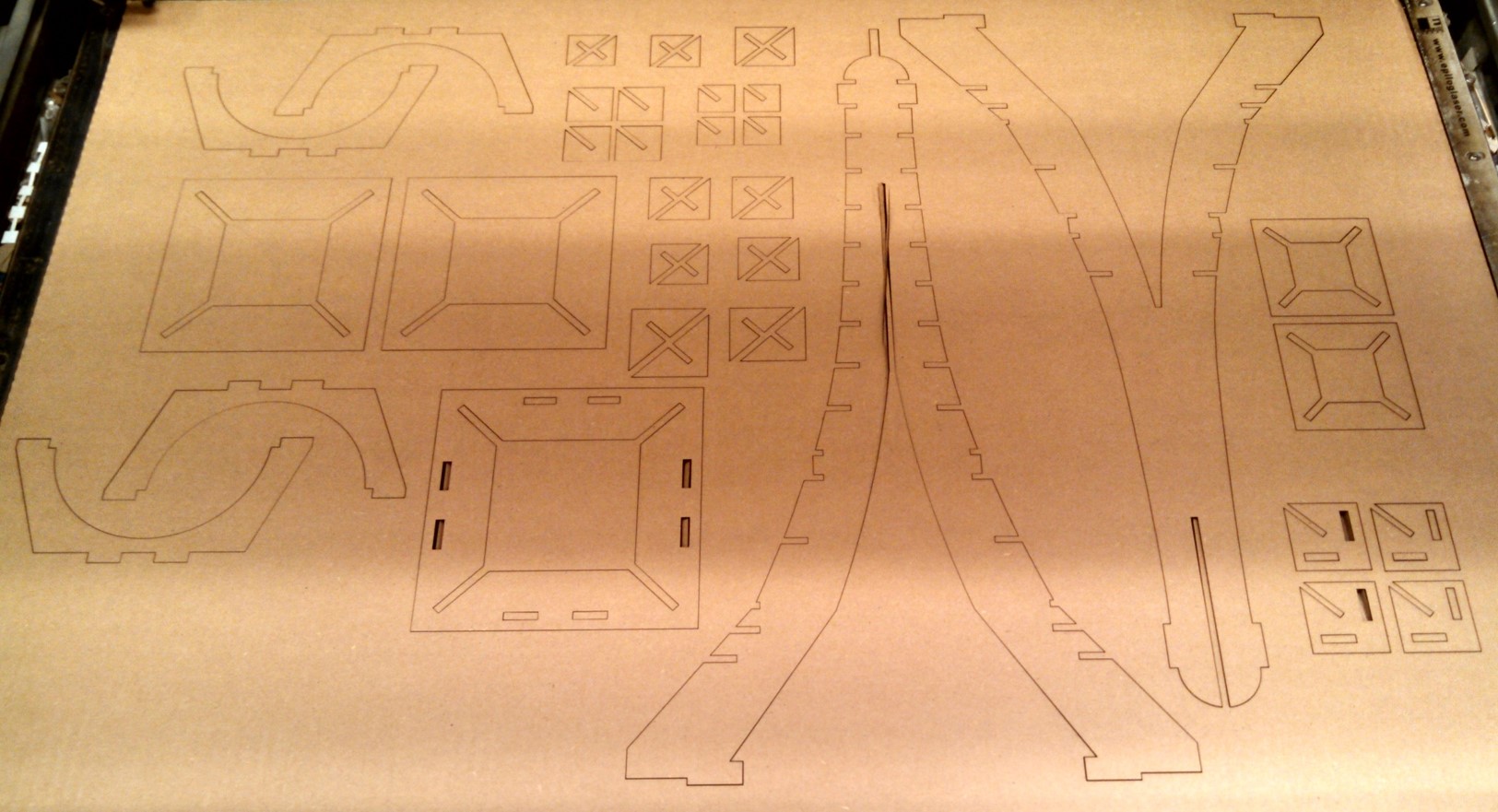

I used SolidWorks to create a 2D model of the different pieces which I saved as a .DXF file so that it could be opened in Rhino and ultimately sent to the laser cutter. When I was modeling the part I realized that it's pretty important to know the exact dimensions of the material that you're working with. I realized the hard way that it's pretty painful to go back and edit your drawing because you got the material thickness slightly wrong. I would suggest that before you start modeling make sure you know exactly how thick the material is.

Using the laser cutter can be pretty tricky the first time. Here are some tips:

1. Make sure both doors to the laser cutter are completely closed before

cutting. Sometimes the machine thinks the door is open even when it looks

closed. It won't cut in this case.

2. Cut out a small piece to make sure you have the settings correct

3. Cut the part twice before you move the material to be sure the cut made

it all the way through

After I had finished working with the laser cutter I thought I'd try

using the vinyl cutter to make a few stickers for my computer.

I noticed two main things about the vinyl cutter. First, the force

setting is really inconsistent. Sometimes a force would cut through

while other times it wasn't enough. The other thing I noticed was

that the machine was really finicky. Sometimes the cutter wouldn't

do anything after I sent a job. I wasn't able to figure out what was

wrong but eventually it just worked.

The biggest issue I ran into was selecting the wrong tolerance for the thickness of the cardboard in the press-fit construction. Initially, I chose a tolerance that was far too big which resulted in the pieces being too loose. In the end I chose a gap size of 0.15 inches for all the slots which seemed to work very well.

The second problem I had was in overestimating the ability of the carboard to flex. I assumed that the cardboard would bend enough to allow me to fit some tight parts on easily but this turned out to be a bad assumption. I actually ended up tearing the first iteration of the tower trying to assemble it. I then had to adjust my SolidWorks model to accomodate for tight fits but once I did this the second iteration worked very well.