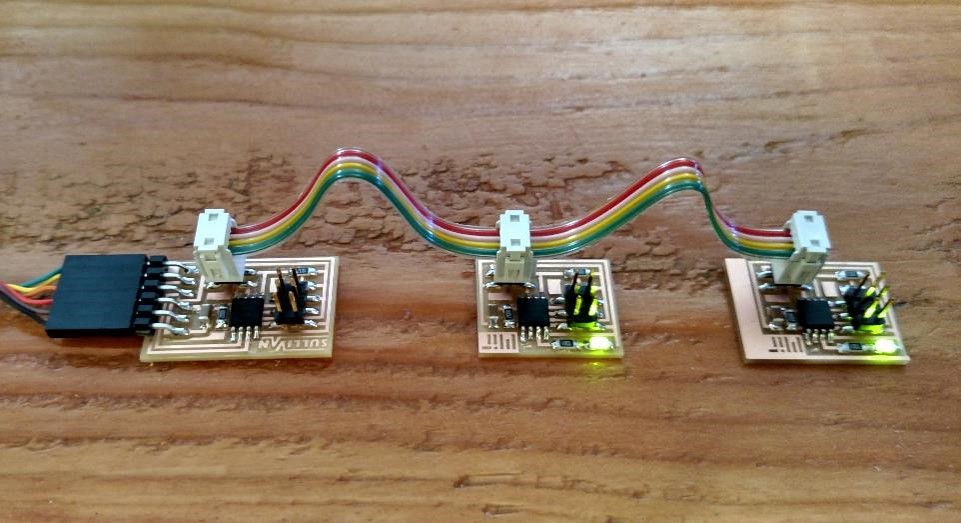

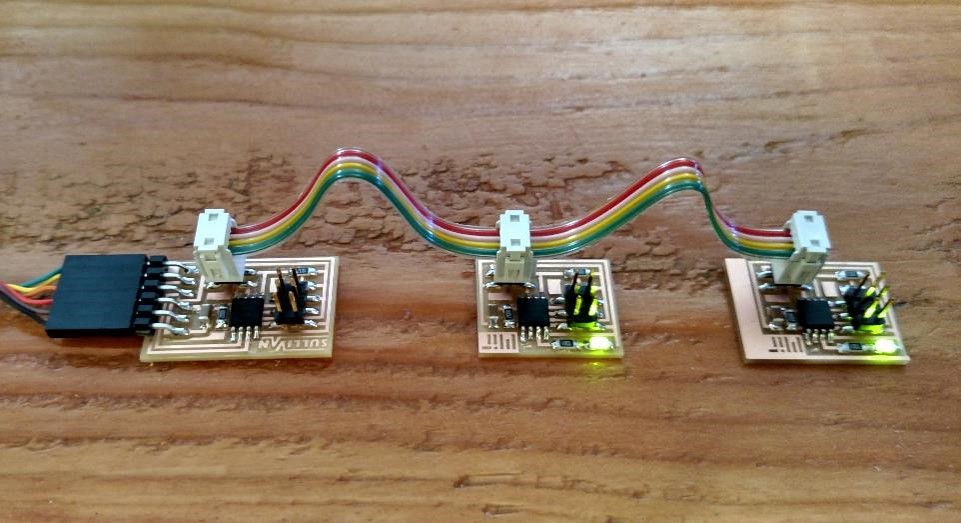

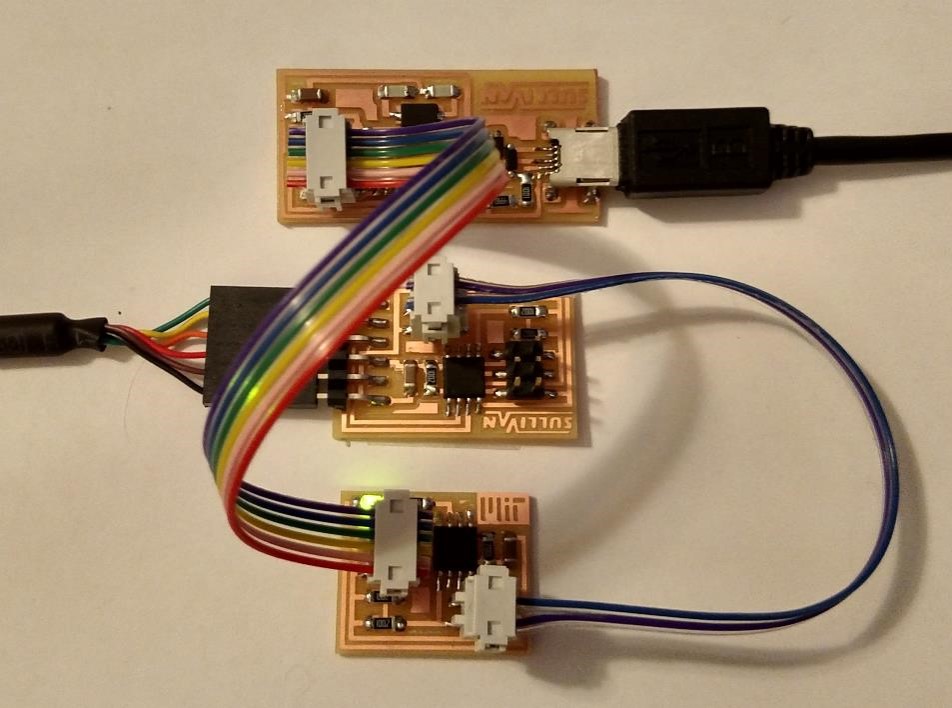

The objective for this week was to design and build a network

connecting at least two processors. I tried to use I2C

but I wasn't able to get it to work.

The objective for this week was to design and build a network

connecting at least two processors. I tried to use I2C

but I wasn't able to get it to work.

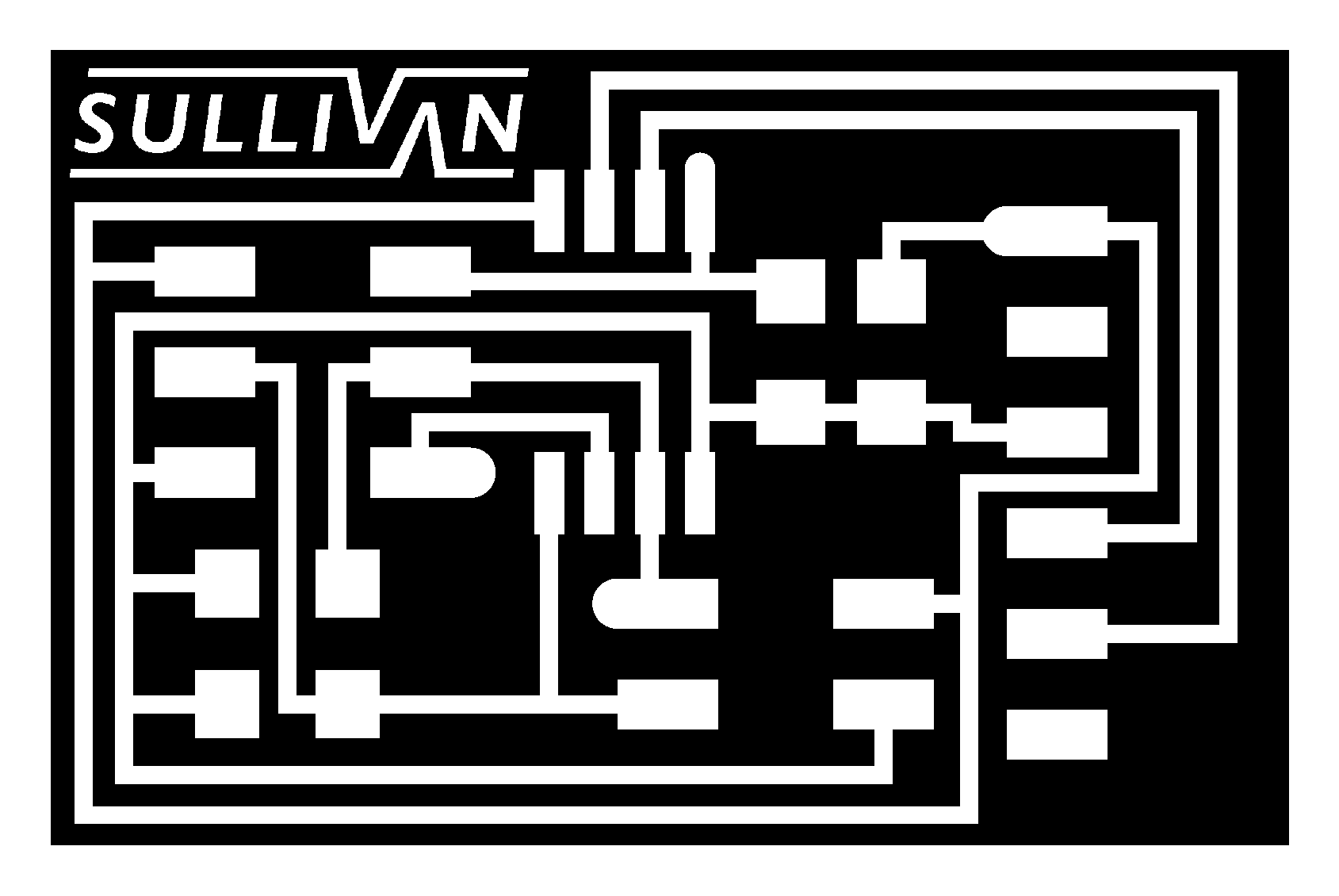

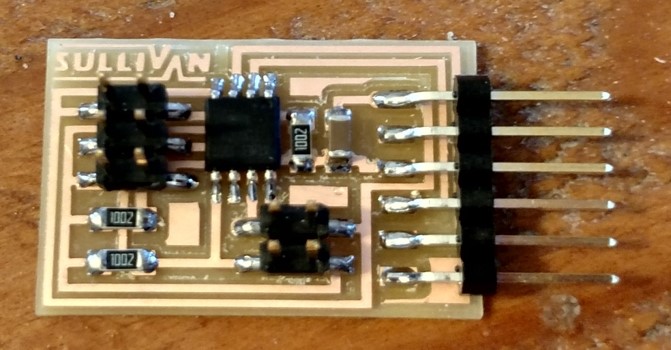

My plan was to replicate Neil's I2C board and get used to

the fundamentals then move to more complicated stuff so initally I

left his design alone.

My plan was to replicate Neil's I2C board and get used to

the fundamentals then move to more complicated stuff so initally I

left his design alone.

This week I ran into several problems with the Roland Mill. First

I noticed that one of the set screws was badly stripped so I had an

end mill fall out while the Roland was running.

This week I ran into several problems with the Roland Mill. First

I noticed that one of the set screws was badly stripped so I had an

end mill fall out while the Roland was running.

My biggest mistake was underestimating the difficulty of programming with I2C and not making the asynchronous boards as a back up before I left.