Week 3: 3D Printing and Scanning

3D Printing

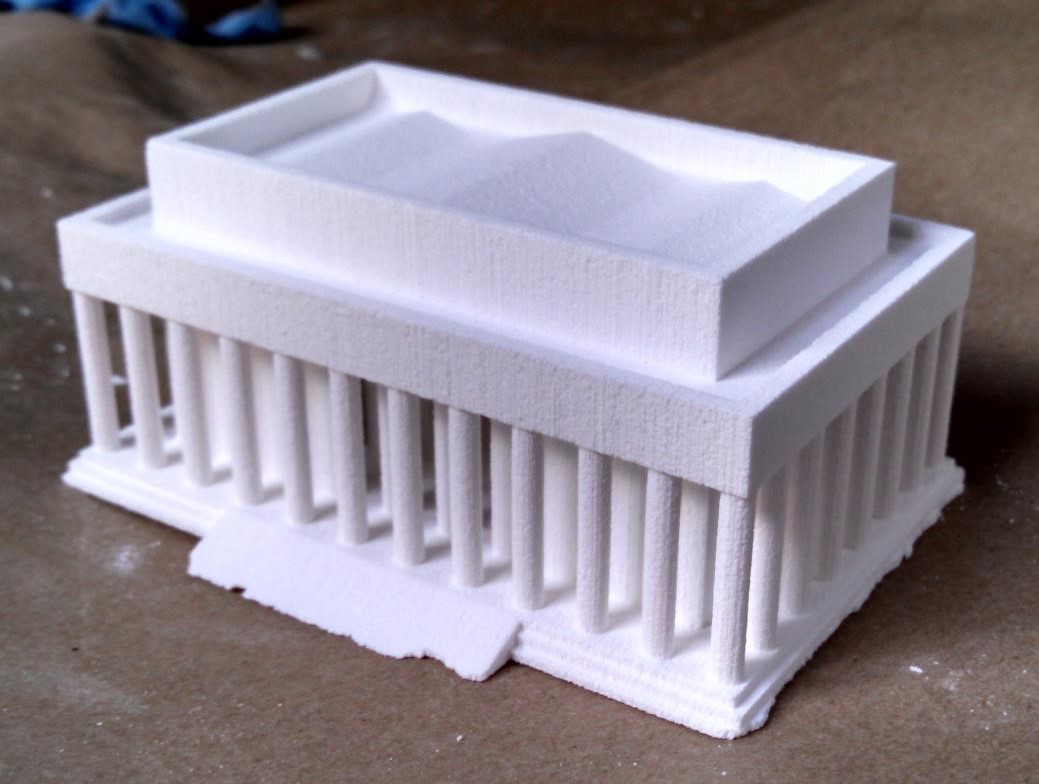

The objective for 3D printing was to fabricate something that

couldn't be fabricated subtractively. I chose to design a miniature version

of the Lincoln Memorial, with the Lincoln Statue nested inside.

Modeling

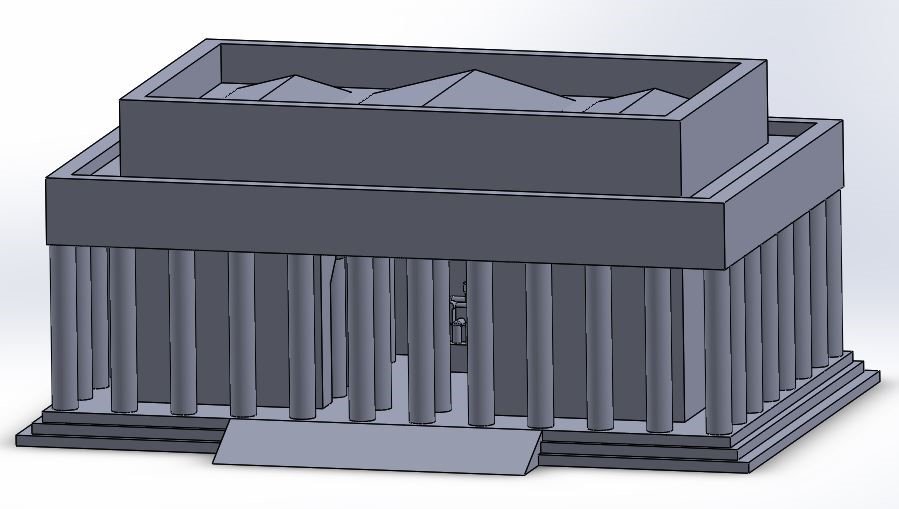

Using Google images and Google Earth, I determined the dimensions of the

Memorial then scaled everything down and built a model in SolidWorks. I

decided to leave out any decoration on the building since the features were

so small I figured they wouldn't print out properly anyways. Inside the

building are 9 nested objects: 8 columns and the statue of Lincoln. None

of these could be made with a mill.

Printing

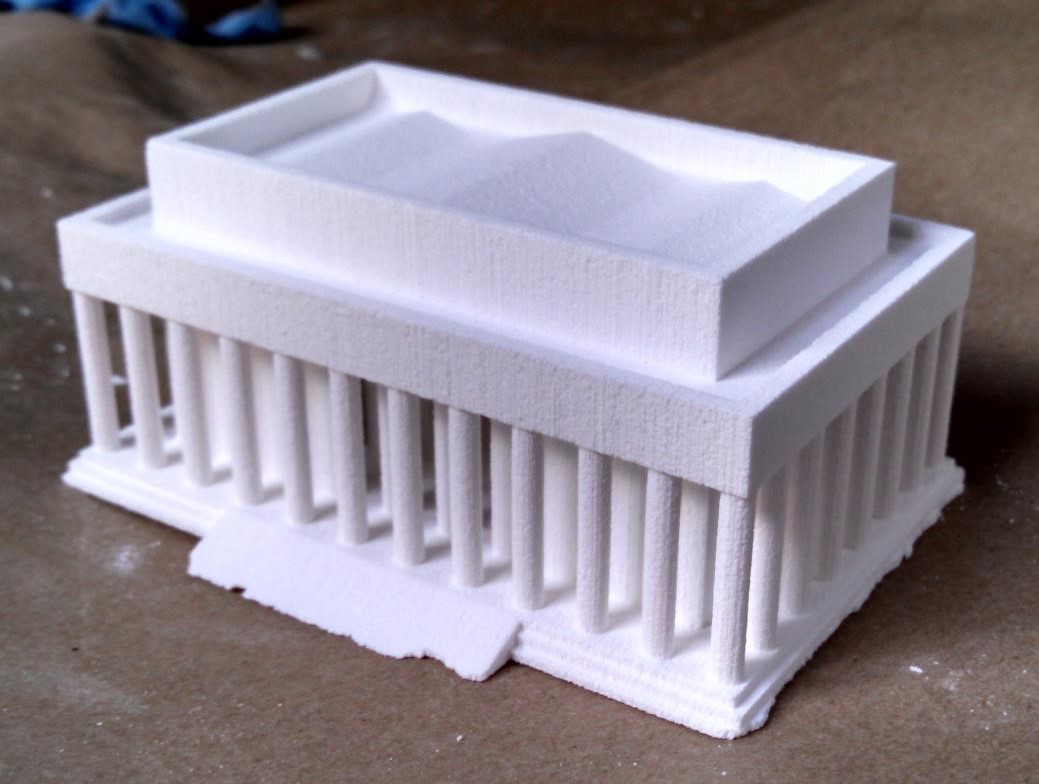

I chose to print my design on the ZCorp printer which uses a fine powder as

the printing medium.

By far the most difficult part of this assignment was

carefully extracting the part. I underestimated how weak small parts are on

the ZCorp prints. Before I even got the part out, the steps around the bottom

began to dissolve away. Just touching parts with a brush would cause

them to crumble. This gave me a better idea of what minimum thickness is

required on the printer (anything thinner than 3mm is likely to fail).

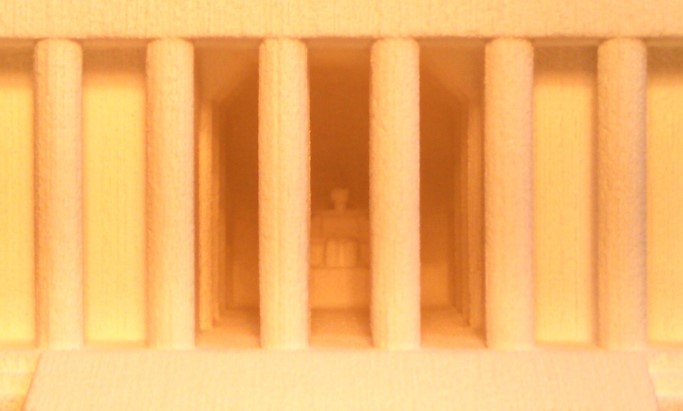

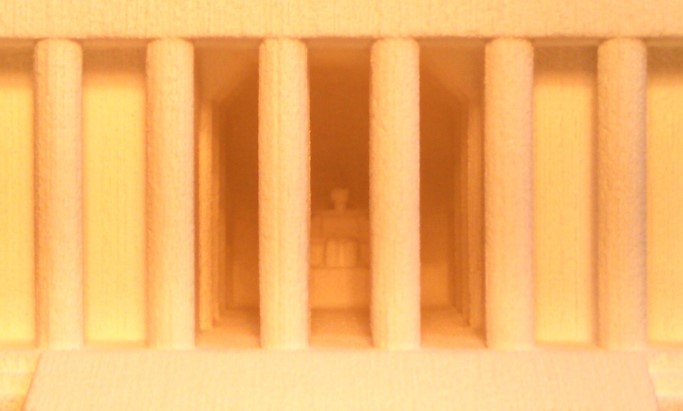

If you look closely you can see the little statue of Lincoln inside the

building. The statue is about 13mm tall and 8mm wide. The overall part is

about 10cm long, 6.5cm wide, and 5cm tall.

To make the part stronger I coated the entire thing in super-glue which

worked really well. I was surprised how much stronger the part became. The

only downside is that it used a lot of superglue and I would suggest coating

it in a well ventilated area because the fumes burn your eyes pretty badly.

Mistakes I made

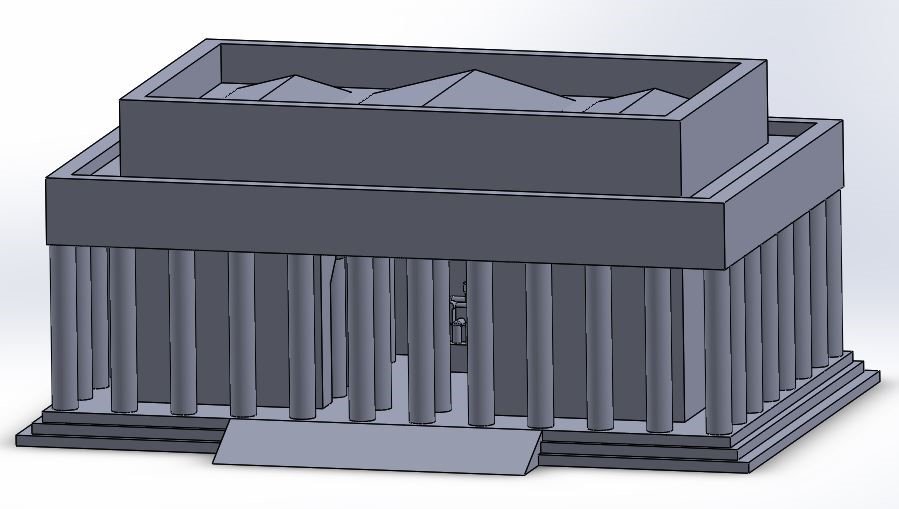

My biggest mistake was making the bottom step of the building way too thin.

Even worse I modeled the stairs at the entrance as an extruded triangle in

SolidWorks so the tip of the triangle was way too thin for the printer to

make without being extremely brittle.

I would suggest making every exposed feature at least 3mm thick or it will

crumble when you extract the part. My Lincoln Statue was actually much

thinner than 3mm in many areas but it's protected within the building.

3D Scanning

For the 3D scanning assignment I was pretty uncreative and scanned my

shoe. Here's the result:

At first I tried to use 123D Catch but it turns out my phone's camera is

pretty messed up so I had a lot of trouble getting nice images.

Then I decided to use the Sense. My first two attempts were terrible. The

camera kept losing the image and it was making pretty strange models. Then

I got the hang of it and realized that if you just go around and point the

Sense at the white spots in the image it will start to fill in the spots.

Once all the white areas are filled in you'll get a really nice model. You

can see above that the model of the shoe is almost identical to the

real thing.

Mistakes I Made

When I was using the Sense I realized I was moving too fast and I was

getting too close to the object. Once I slowed down and moved away I got

much better results. Also many passes produce a much better result than

only one or two. Using the Sense is a trial and error experience. It becomes

easier when you actually use it.