Background

Before, I was using a plastic Sterilite organizer as my bedside table

which didn't work too well. The top would always come off and it

sagged so everything fell toward the center. It looked pretty

terrible too, as you can see from the picture.

So I decided to make a table that was stronger and that looked a

little better too. I wanted to use the old drawers since they seemed

to work pretty well.

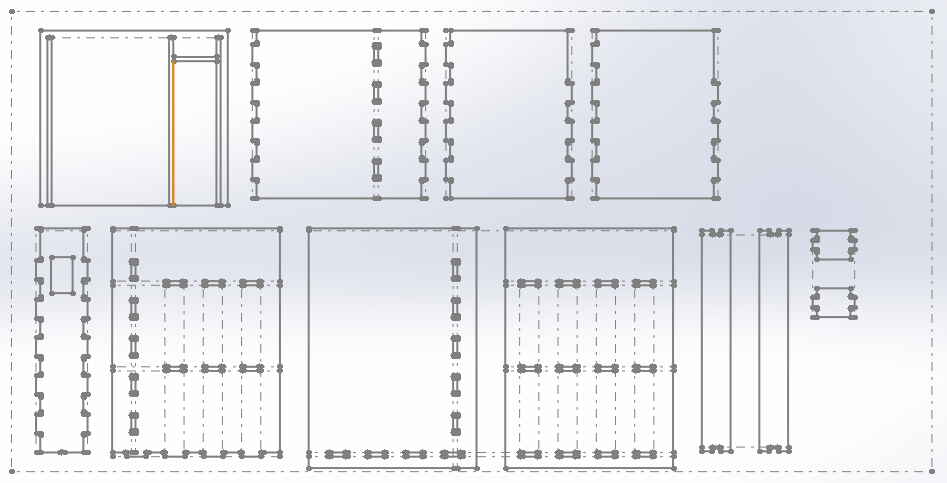

Modeling

I used SolidWorks to create a 2D sketch of all the parts.

I used the OSB but unfortunately I didn't measure the thickness

beforehand and I used 7/16 inch (0.4375 inch) which turned out to be too

small.

To hold all the pieces together I used 2 inch tabs sparated by 2

inch gaps with 0.125-inch-radius "dogbones". This worked great for

my design. For the top piece I cut a pocket down to about half the

thickness of the material which worked well except for a few minor

issues that I'll explain later.

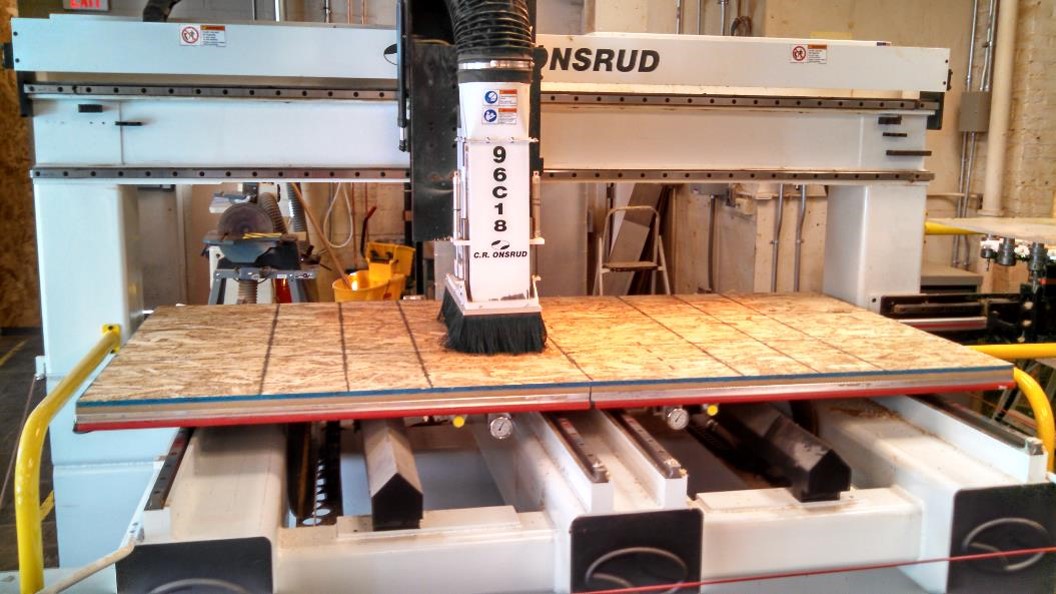

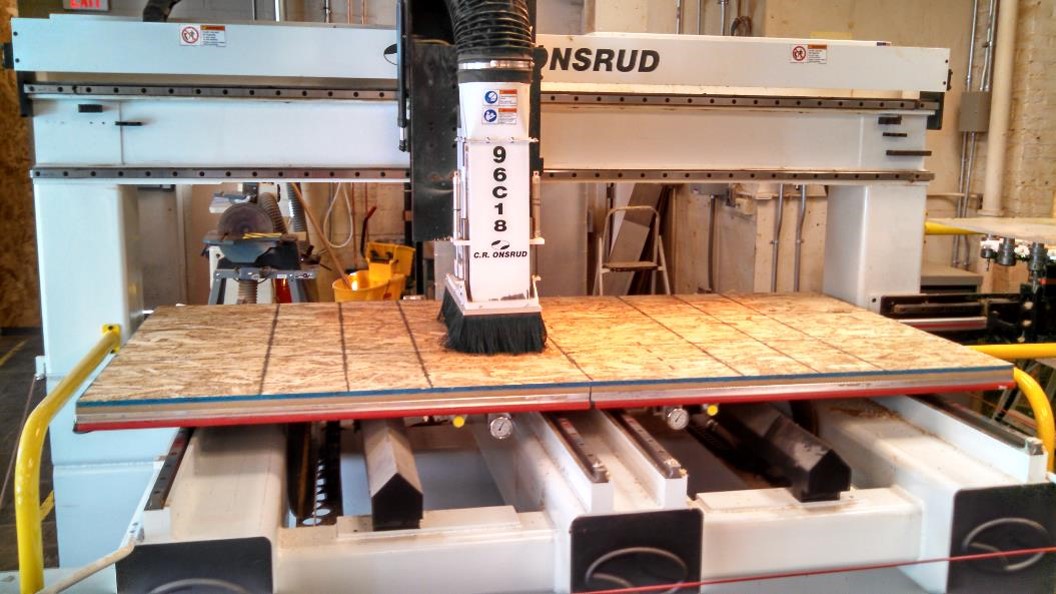

Milling

Milling was pretty straightforward but I made a lot of little

mistakes. Going back to the pocket cut that I was talking about

before. I made two small but annoying mistakes.

First, I used a compression bit to mill out the pocket which

required a cut depth of about 0.25 inches; however, the compression

bit only works on cut depths larger than about 0.375 inches. As a

result, my pocket ended up with a really gnarled edge.

Secondly, my pockets shared an edge with the outer edge of the piece.

It's not really obvious but since we set different tool paths for

the pocket and the outer edge then the pocket needed the dogbone

shape even where the mill was going to already cutout the part

completely. I didn't realize this so I had to chisel out the

remaining fillet by hand.

Finally, I didn't accomodate for small pieces moving during milling

which I should have because the two smallest parts in my design

popped out and got pretty mangled.

Also, like I said before, the thickness of the OSB was thicker than

I had anticipated so nothing fit properly at first. Then Chris

Dewart from the Architecture Wood Shop helped me cut off about 5

mills from all my tabs to allow the pieces to fit.

-

Front

-

Back

The Finishing Touches

Finally, I added the drawers from the old Sterilite organizer and

painted the table black. Then I wrapped some paper in front of the

Christmas lights to give it a diffuse glow. I just used paper to show

the effect but eventually I plan on finding a better material.

Finally, I added the drawers from the old Sterilite organizer and

painted the table black. Then I wrapped some paper in front of the

Christmas lights to give it a diffuse glow. I just used paper to show

the effect but eventually I plan on finding a better material.

The finished product looks better than I expected and the

light works great! The drawers fit perfectly and now I have an outlet

that's easier to reach.

Mistakes I Made

The biggest mistake I made was not measuring the OSB before milling

the parts. It made a bunch of little problems after the parts were

milled. It wasn't a huge issue but it did add some hassle. All the

other mistakes I made were explained before and weren't that big

of issues.

A small mistake I made that I never mentioned before was that I

made the dogbone radii a little too big. This forced the machine to do

multiple passes to remove the exess material. It doesn't seem like

much but it doubled the milling time for all my parts. If I were to

do it over again I would have made the diameters equal to the tool

diameter.

Finally, I added the drawers from the old Sterilite organizer and

painted the table black. Then I wrapped some paper in front of the

Christmas lights to give it a diffuse glow. I just used paper to show

the effect but eventually I plan on finding a better material.

Finally, I added the drawers from the old Sterilite organizer and

painted the table black. Then I wrapped some paper in front of the

Christmas lights to give it a diffuse glow. I just used paper to show

the effect but eventually I plan on finding a better material.