Week 6: Molding and Casting

The objective for this week was to design and machine a 3D mold

and cast parts from it. Since time was short this week I decided

to keep it simple and make a mold of Texas.

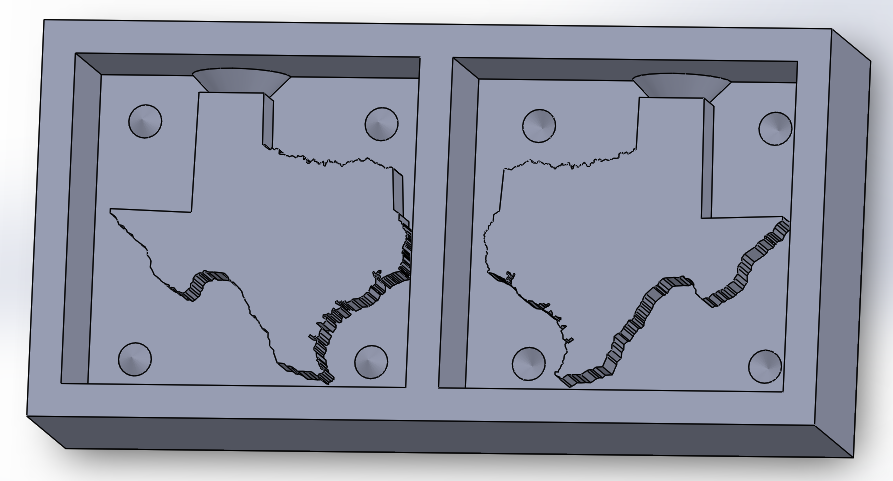

Modeling

I used SolidWorks to design the 3D mold. To make the intricate

shape of Texas I simply used the "Sketch Picture" feature in

SolidWorks under the "Tools" menu:

Tools > Sketch Tools > Sketch Picture...

This allowed me to import a .png of the outline of Texas as a sketch

which I just manually traced. This was very easy and worked out

great. This process kept my SolidWorks model extremely simple and as

a result I had no problem at all opening it in Mastercam.

Mastercam

By far Mastercam seemed to be the most difficult part of the

assignment for most people including myself. Luckily I had a ton of

help from

Austin Smith.

Before getting Austin's help several of us were in the architecture

shop for hours just trying to get our models ready in Mastercam.

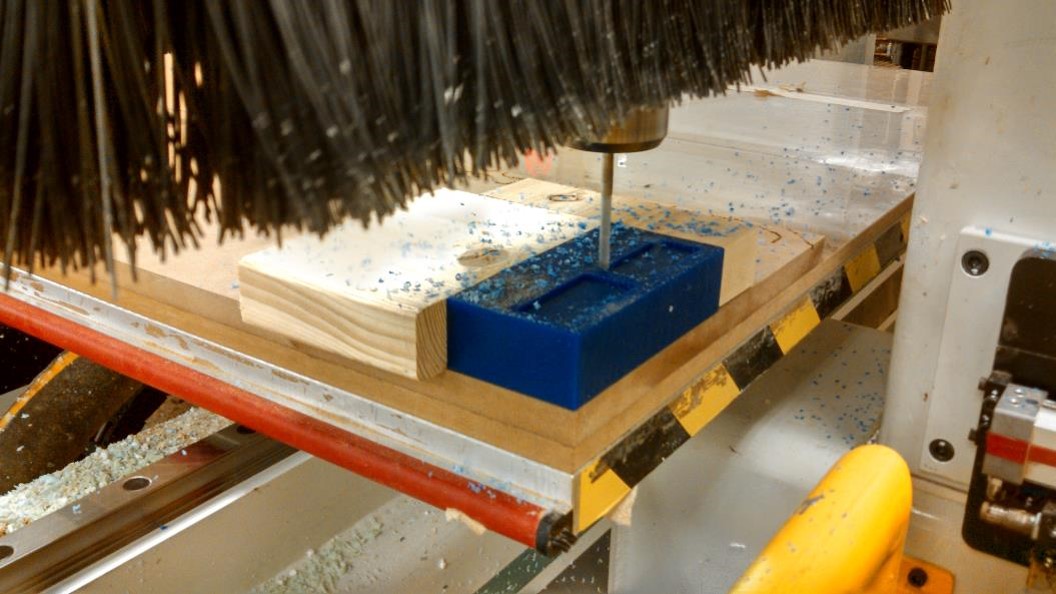

Milling

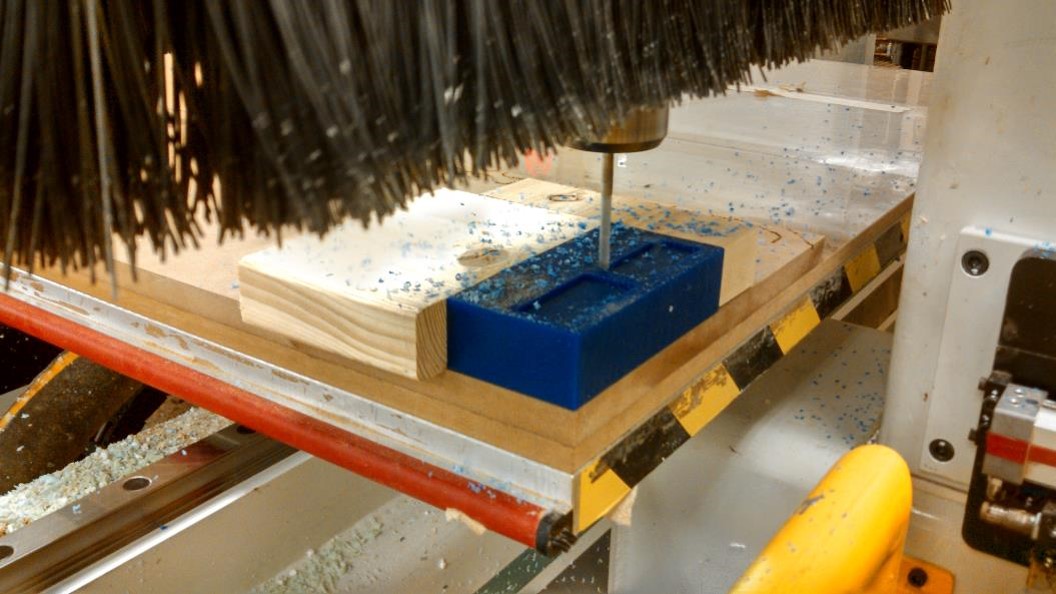

In order to get Austin's help it meant working in the Architecture

Wood Shop with the large Onsrud mill.

Since the wax block is so much smaller than the bed of the Onsrud we

had to fix it to a larger piece of scrap wood which you can see in

the above image. This extra surface area allowed the vacuum to work.

We hot glued the bottom of the wax and then surrounded it by small

blocks of wood to keep the material fixed.

In the end the Onsrud was much faster at milling than the Shop Bot

or Modela but still took about 30 minutes to completely mill out the

mold.

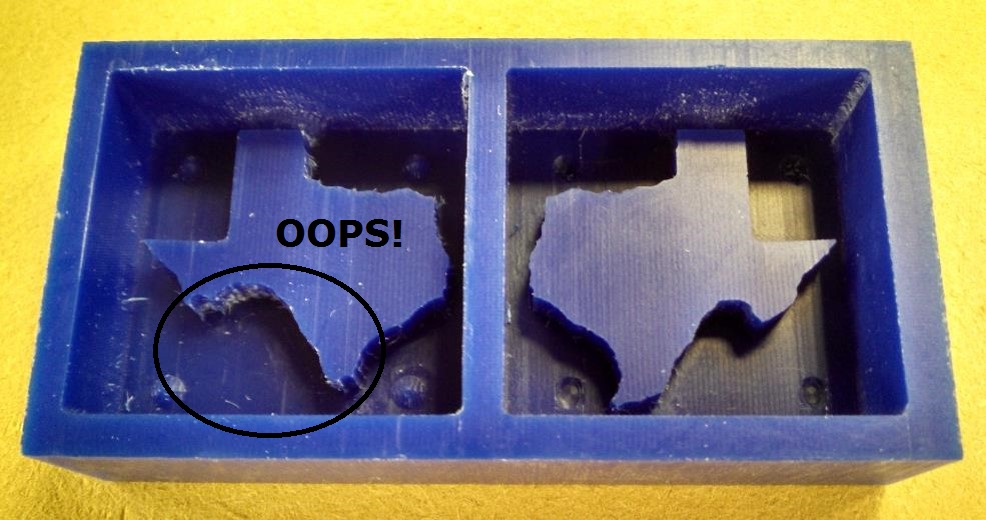

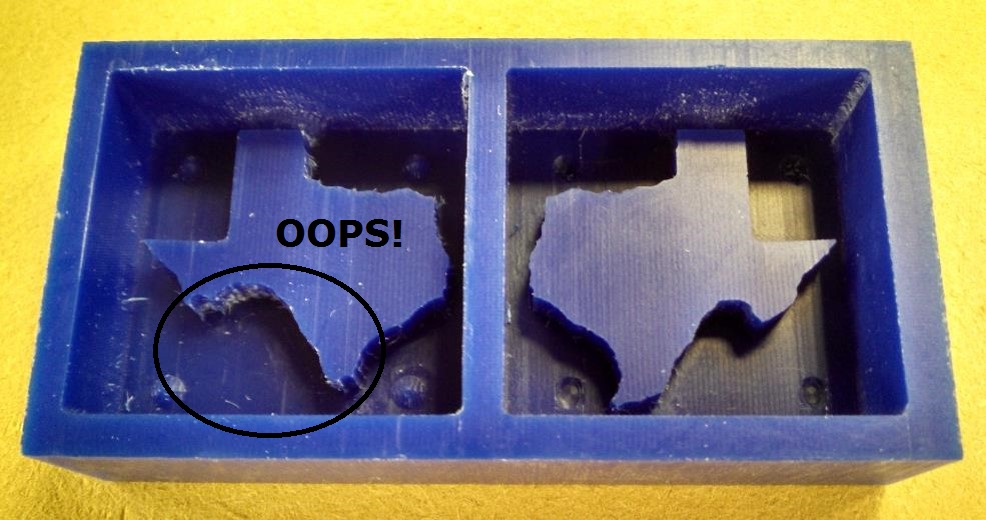

Everything went great until the last minute of milling where, for

some reason, the Onsrud began to cut into the Mexican border of the

Texas mold, which you can see on the left side of the image above.

Luckily we noticed this quickly and stopped the machine before

it could continue to mess up the shape.

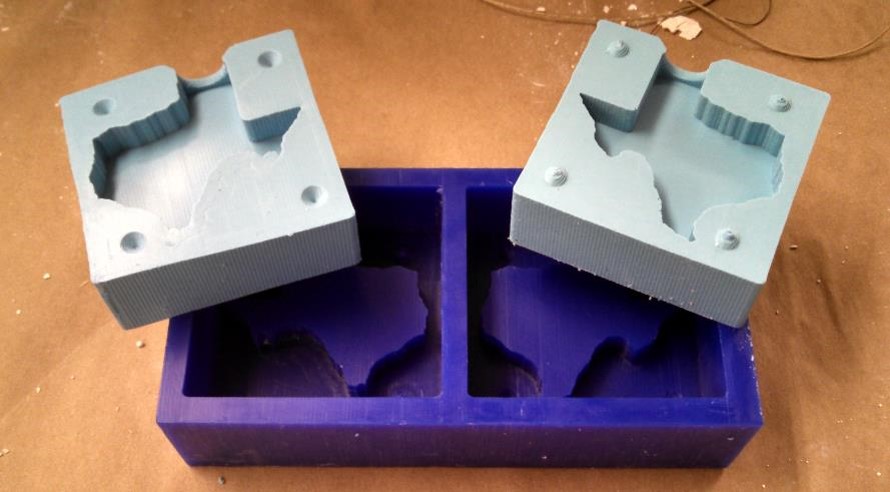

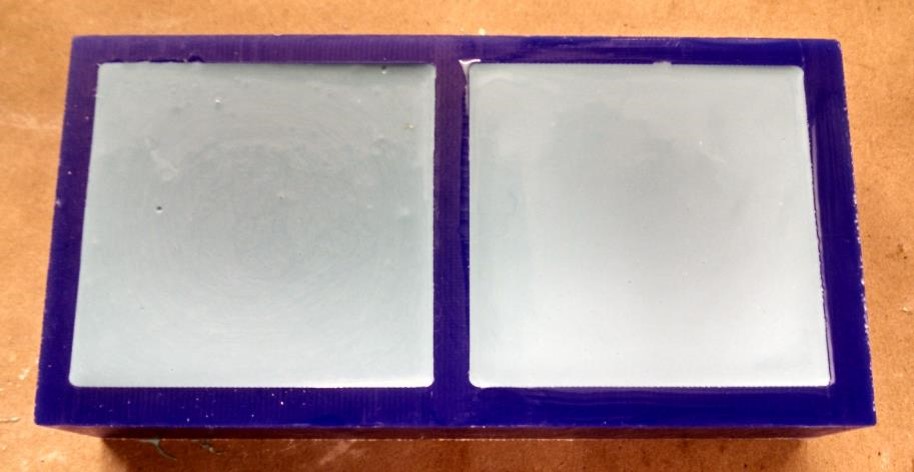

Creating the Negative

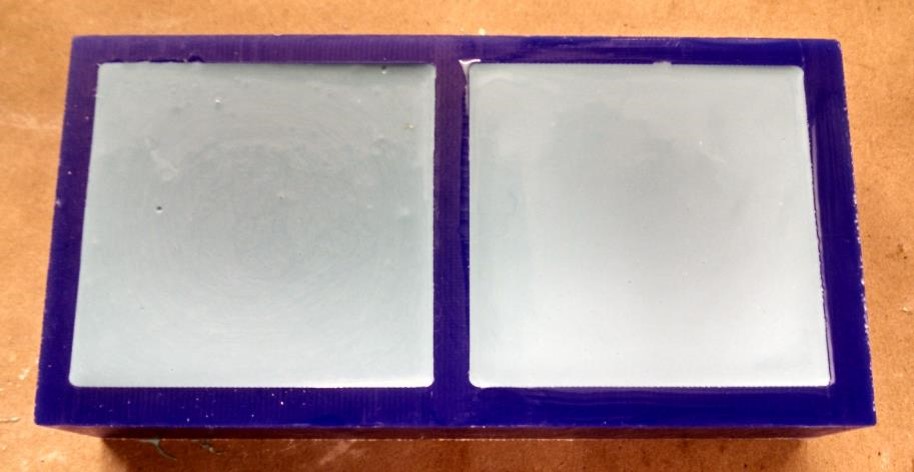

Once the wax was totally machined I started making the negative with

Oomoo. I simply followed the directions on the box which were

very simple and straightforward, although I would suggest waiting

longer than the recommended 75 minutes for the Oomoo to cure. I

waited about 85 minutes and the Oomoo came out a little tacky. I

would suggest waiting about 2 hours for the Oomoo to fully cure.

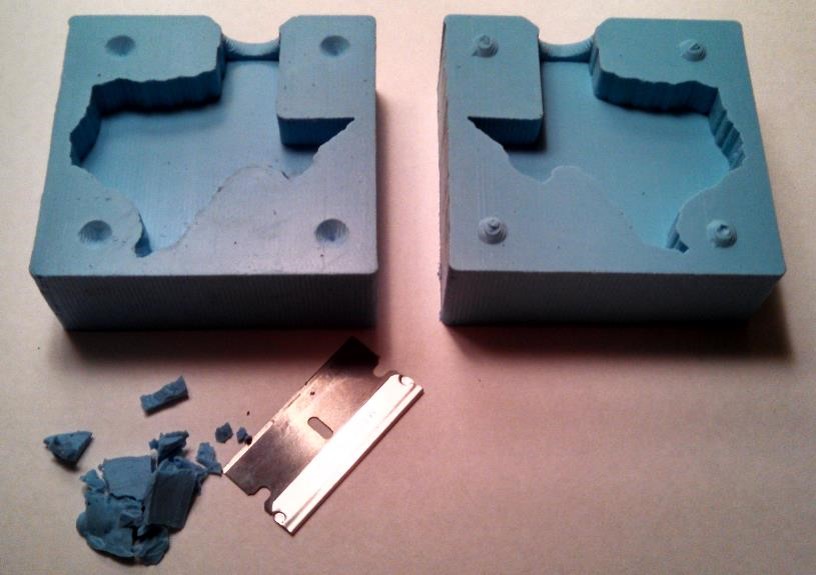

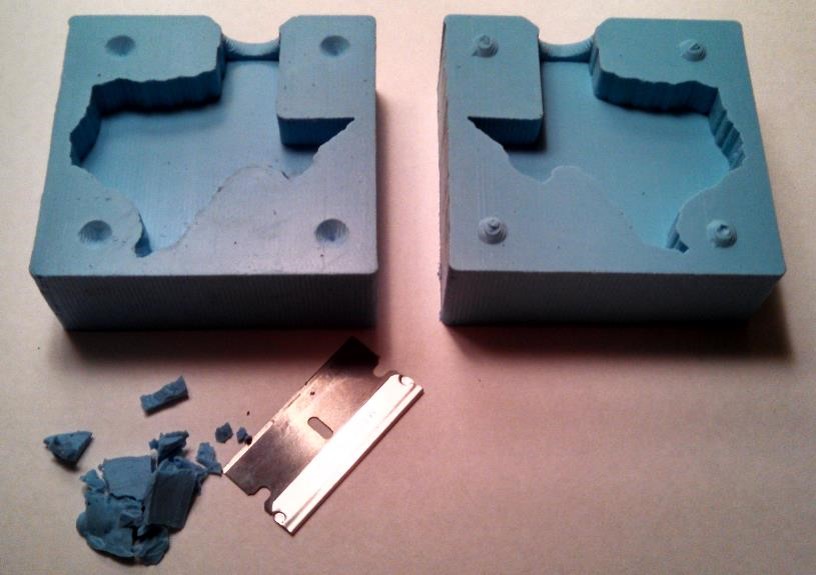

After I took the Oomoo out I decided to try and fix the part where

the Onsrud had cut into the border using a razor blade.

As I expected this wasn't very easy to do aesthetically. After

cutting the Oomoo it came out pretty jagged and ugly. I would

suggest fixing any mistakes on your wax mold before making the Oomoo.

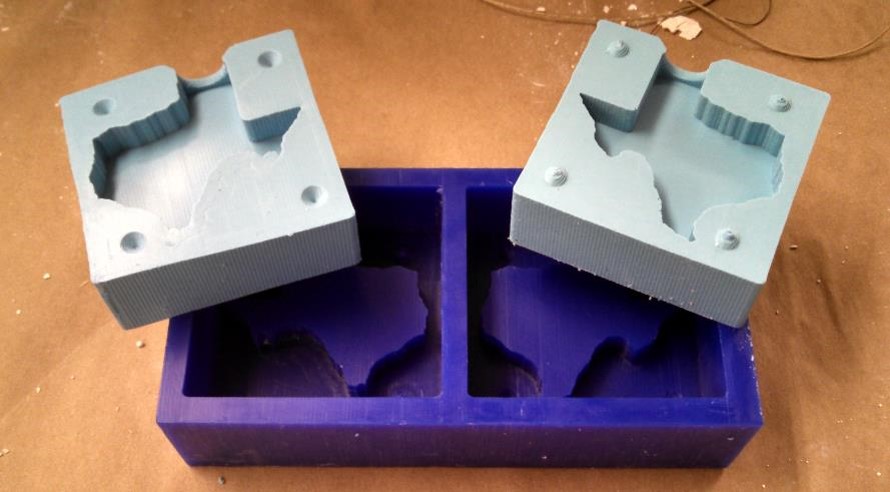

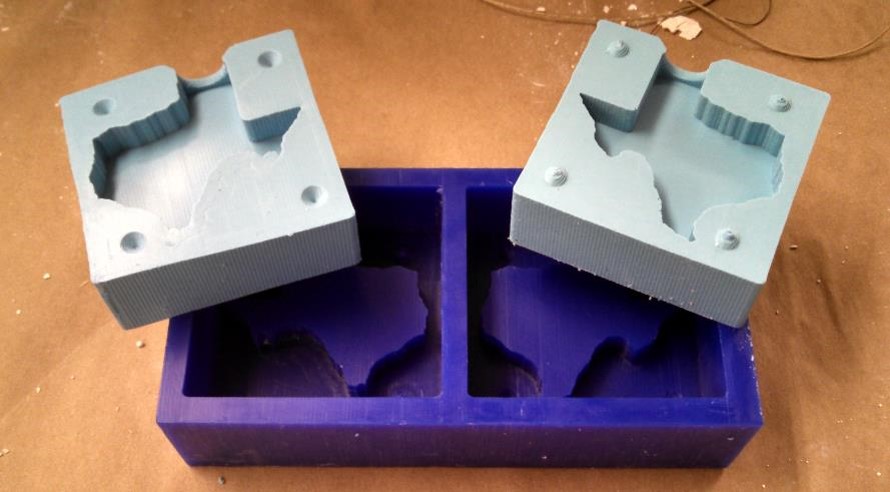

Casting

Unfortunately, since I started this assignment so late I ran out of

time and never had a chance to cast any parts out of my mold.

Eventually I plan on casting some parts but since half of my mold is

messed up I will most likely just use the good half, making the part

half the thickness.

Mistakes I Made

By far the biggest mistake I made was starting this assingment too

late. This assignment is extremely time consuming and even more so

when there are several other people also trying to get their parts

machined.

The second biggest mistake I made was trying to use the Shop Bot. If

the Onsrud is not being used I would highly recommend making your part

with it because it's much faster than the other mills.

Like I said before, another mistake I made was removing the Oomoo

while it was still tacky. This seemed to be fine but just in case I

would suggest waiting 2 hours before extracting the Oomoo.

Finally If I could have a do-over I would have figured out why the

Onsrud cut into my design and tried to fix that, and if I had more

time I would have tried to actually cast a part from my mold.

After I took the Oomoo out I decided to try and fix the part where

the Onsrud had cut into the border using a razor blade.

After I took the Oomoo out I decided to try and fix the part where

the Onsrud had cut into the border using a razor blade.