Week 8: Composites

The objective for this week was to design and make a 3D mold and

produce a fiber composite part from it. I made a replica of Majora's

Mask.

Background

My brother is a video game developer and he asked me to make a

replica of Majora's Mask for him.

Majora's Mask is a Nintendo 64 video game

that was released in 2000.

Surprisingly, replica's on the market sell for hundreds of dollars!

Modeling

I used SolidWorks to model the mold. In order to get an accurate

representation I used the "Sketch Picture" feature in SolidWorks

under the "Tools" menu:

Tools > Sketch Tools > Sketch Picture...

This allowed me to import a .png of the image which I traced over

with splines. I just eye-balled the depth and created a solid body

using the "Lofted Boss/Base" feature.

Once the main body was complete I added the spikes by creating a

series of planes with extruded cones extending from them.

Once the features were complete I mirrored the object making a

symmetrical 3D representation of the mask.

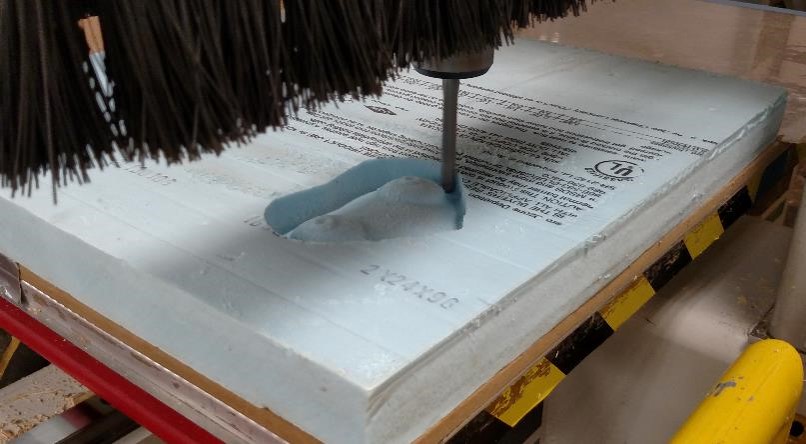

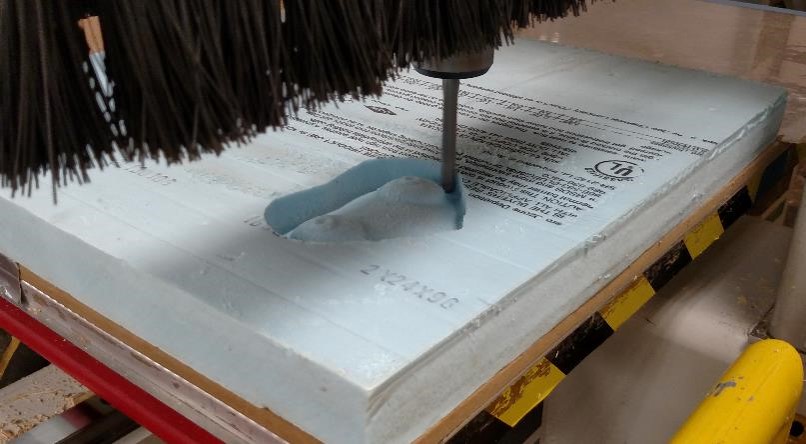

Milling

Milling on the Onsrud with the blue foam is extremely fast and easy.

This is a huge contrast to Molding and Casting Week where the most

tedious and painful part was milling the fine details out of the wax

blocks.

The entire process only took about 20 minutes. I only used a 0.5

inch ball end mill for the entire cut. The foam didn't require any

roughing cuts which significantly reduced the time.

The mold came out very clean. All I had to do was clean up the outer

profile of the mold with scissors which was trivial.

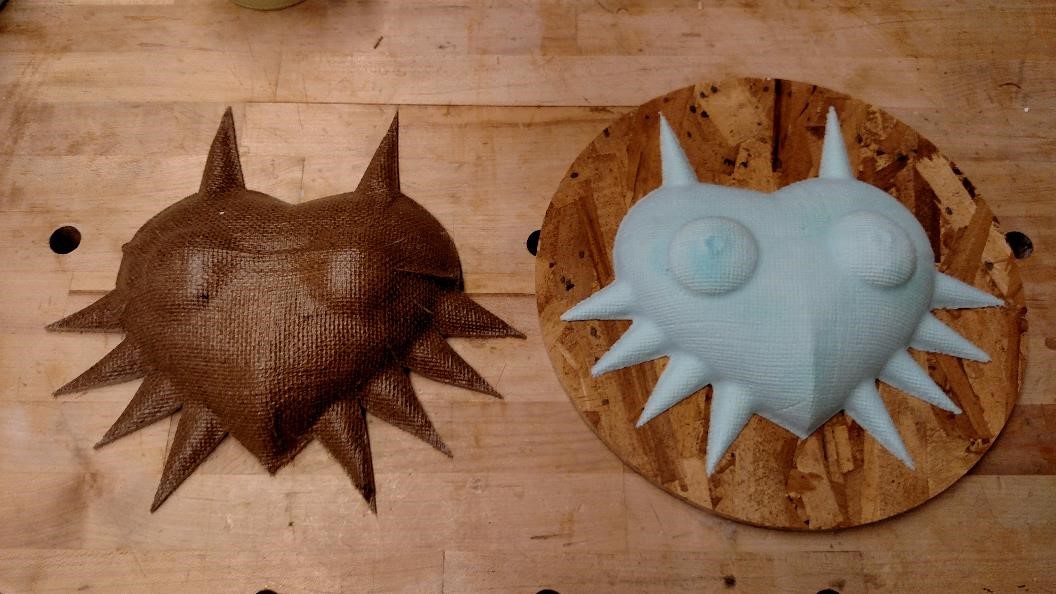

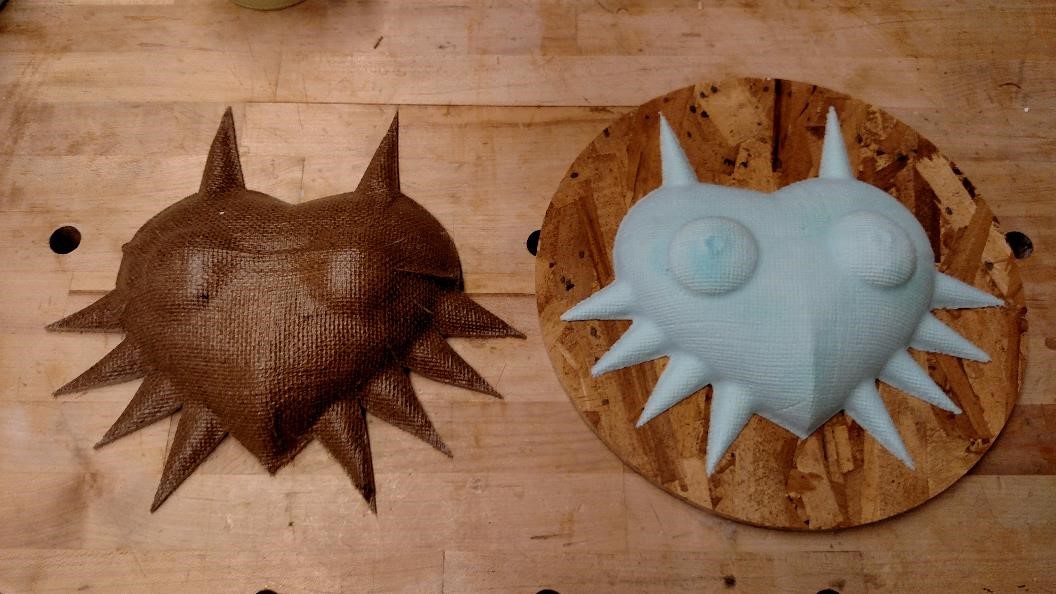

Preparing the Composite

The first thing I did to prepare for making the composite was

glue the foam mold to a wooden support. I did this because the

spikes seemed to be pretty fragile. I used Guerilla Glue and found

a round piece of scrap OSB in the Architecture Wood Shop.

Once the glue had cured I sprayed the mold with "Mold Release" to

help make sure that extraction wouldn't be difficult. Here are the

layers I used on top of my mold:

1. 1 sheet of Saran Wrap

2. 6 sheets of resin coated burlap

3. 1 sheet of pink perforated film

4. 2 to 3 layers of bleeder padding

Vacuum Bagging

In order to save time

Tim Fallon,

Jeff Clayton

and I combined our projects into one vacuum bag and allowed it to

cure for 4 hours. This seemed to work very well.

Since my mold had small radii of curvature, I wanted to make sure

that before I put the layers in the bag I prevented any wrinkles

that could occur.

I laid one ply of burlap over the mold and noticed stress points at

the top and bottom of the design. To prevent wrinkling I cut small

darts at both points which seemed to work pretty well.

Extraction

Extracting the part was extremely easy. The bleeder and perforated

layers peeled right off and the Saran wrap did a great job of

keeping the burlap from sticking to the mold.

When I took the part out I noticed a few wrinkles and the detail on

the eyes got smashed by the vacuum but over all the part turned out

better than I expected.

Cutting the Excess

I tried a bunch of methods before I was able to cut out the mask:

First, I tried cutting the excess with scissors which weren't strong

enough.

Then, I tried wire cutters but they were too stubby to make

good progress.

Next, I tried a hacksaw but the material wasn't rigid

enough for the saw to make accurate cuts.

Finally, I decided to try the bandsaw which worked great! I was even

able to cut between the spikes.

Mistakes I Made

The biggest mistake I made this week was not making the scale

of the mask correct. Initally I had planned on gluing two layers of

foam together to get the depth I needed to make the mask large enough;

however, I thought it would be too much down time to wait for the glue

to set so instead I just scaled down the mask. I thought it would

still be a good size but after everything was done, it seemed to be a

little too small.

Other than that everything went very smoothly!

Bonus Project!

After I felt more confident with composites I decided to use what I

learned to replace two resistance thermometers (RTD's) that had

failed on the machine I work on for my research.

The RTD's have to be adhered to the surface of the machine so I used

one ply of fiber mesh coated in epoxy and hardener and pressed

tightly to the surface with zip-ties and rubber bands.

The typical cure time for the resin is three days; however, I was

able to control the temperature since the RTD's acted as feedback

sensors for temperature controllers. As a result, I kept the

temperature at 50

oC which reduce the cure time to a

matter of hours.

After the resin cured I cut off the excess mesh and removed the

zip-ties. Now the machine works better than it ever has and produces extremely

consistent data!

I used SolidWorks to model the mold. In order to get an accurate

representation I used the "Sketch Picture" feature in SolidWorks

under the "Tools" menu:

I used SolidWorks to model the mold. In order to get an accurate

representation I used the "Sketch Picture" feature in SolidWorks

under the "Tools" menu:

The first thing I did to prepare for making the composite was

glue the foam mold to a wooden support. I did this because the

spikes seemed to be pretty fragile. I used Guerilla Glue and found

a round piece of scrap OSB in the Architecture Wood Shop.

The first thing I did to prepare for making the composite was

glue the foam mold to a wooden support. I did this because the

spikes seemed to be pretty fragile. I used Guerilla Glue and found

a round piece of scrap OSB in the Architecture Wood Shop.

After I felt more confident with composites I decided to use what I

learned to replace two resistance thermometers (RTD's) that had

failed on the machine I work on for my research.

After I felt more confident with composites I decided to use what I

learned to replace two resistance thermometers (RTD's) that had

failed on the machine I work on for my research.