Week 2: Press-fit construction kit

We were asked to create a press-fit construction kit using cardboard and the laser cutting facility at the machine shop. For this project, I built a simple fractal tree. The idea was to create a 3D shape out of a 2D structure (cardboard, in this case). I wanted to create a set of basic shapes that I could join together based on simple rules, much like the concept of L-systems.

This is what my fractal tree looks like.

This a simple rule where, starting with a seed, every node has two branches, and the angle changes by 90 degrees in each node, with respect to its previous node. I tried a few other rules, but this one seems to work well when it comes to organizing the tree structure into a set of visible and distinguishable patterns. Some nodes are deliberately left out in this case for the sake of clarity. The following pictures show two other views of this structure.

Construction

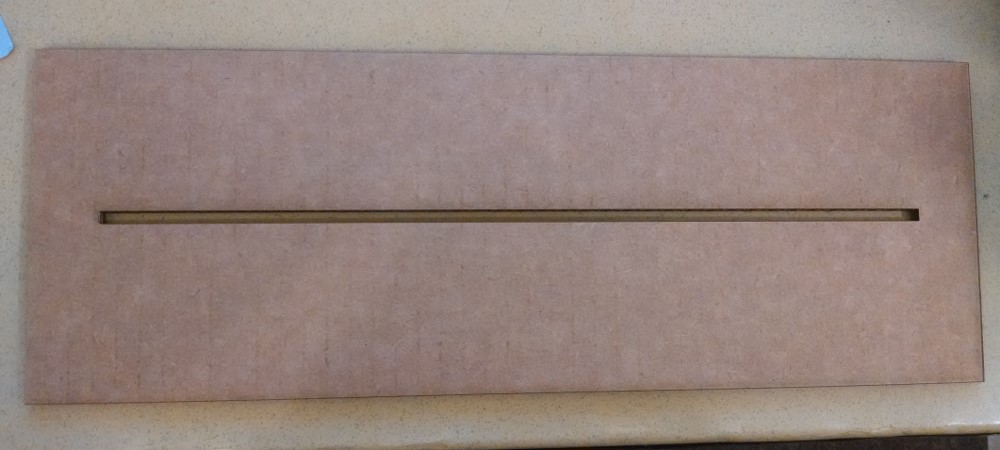

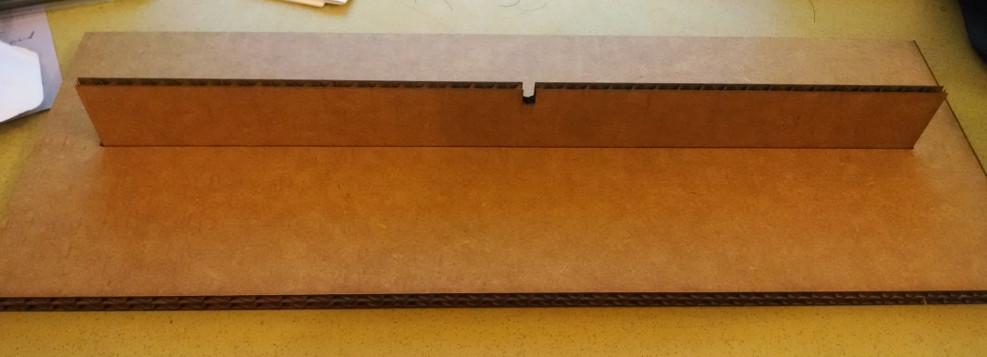

I created a firm base to hold the structure tightly, even when the tree becomes unbalanced, which is quite often the case with L-systems. The base has a 0.166" thick slit, where the support of the tree will fit. I used several base sheets, and pushed the support of the tree though them at once.

The base and support together provides the testbed for playing around with L-systems. The support has a notch in the middle to tightly hold the seed of the system.

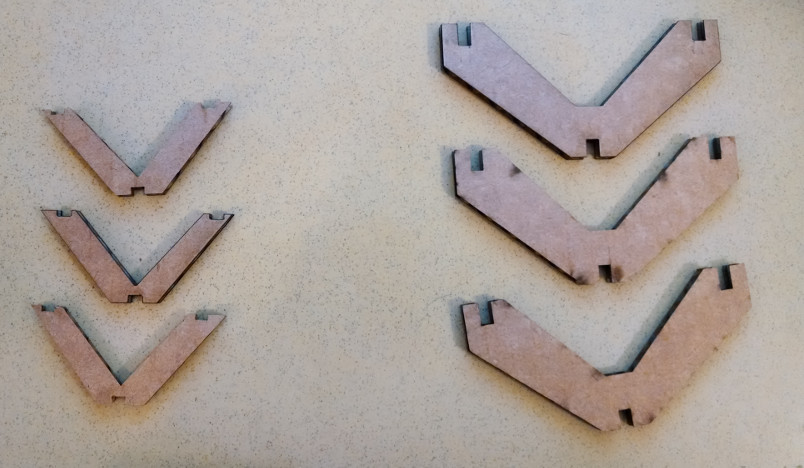

For this particular L-system, I only needed one structure. The construction of this system allows us to change the angle at every step by 90 degrees. I cut them out in several sizes. (Technically, changing the length of the nodes changes the rule too, but here, it's done to create a stable and bigger structure).

Other Attempts

Before I decided on this particular design, I designed and cut out a few other types of units to build a fractal tree. The trials included building bigger nodes and hinges, cutting out thin portions in these branches to make them bendable, smaller versions of those branches, and finally, connectors that should get rid of the hassle of cutting different branches. I particularly liked the connector idea, but did not have plenty of time to play with some feasible connectors (rules) that will give rise to an interesting structure.

Lessons Learned

The laser cutter changes its strength of cutting. This is sometimes the case if the cardboard is not flat, the distance between the laser and the cardboard varies the power, specially if you have auto-focused for the whole board at once.

To cut through completely, sometimes it makes sense to duplicate the cad design and overlay them on top of the same structure. This makes the laser cutter cut as many times as the number of overlays.

Hinges should have rounded corners whenever possible. This makes the press-fit mechanism much easier to work with.

.eps is a reliable format when interchanging cad models between Inkscape and CorelDraw. In the beginning, I tried Inkscape and exported my files to .svg format, to import in CorelDraw in the machine shop computers. The files usually lost their structure when imported in CorelDraw. However, .eps from Inkscape worked fine.