Week 10: Output

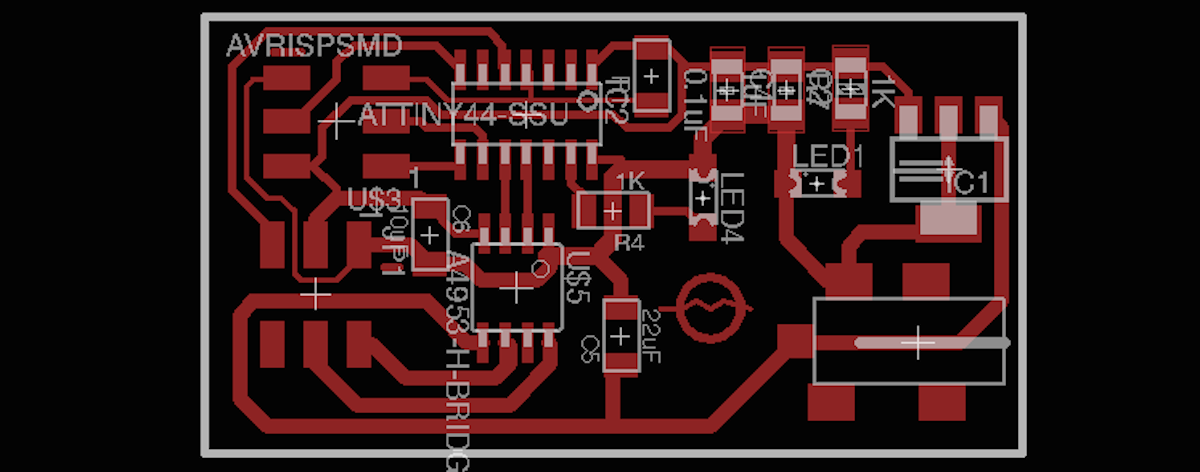

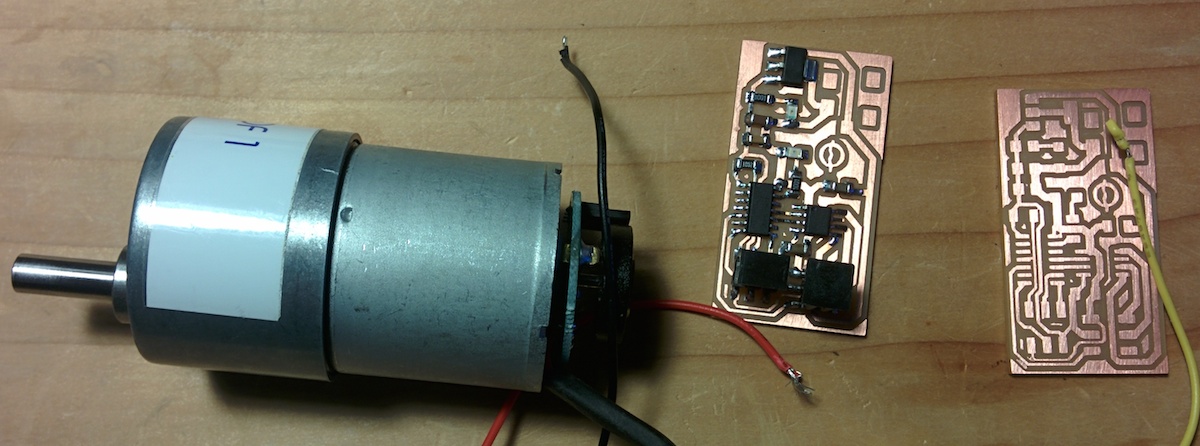

I didn't finish this week's project. I made two boards. One with an hbridge that can drive a motor and a servo to use as a base for a walking robot toy:

This was an easy mill job:

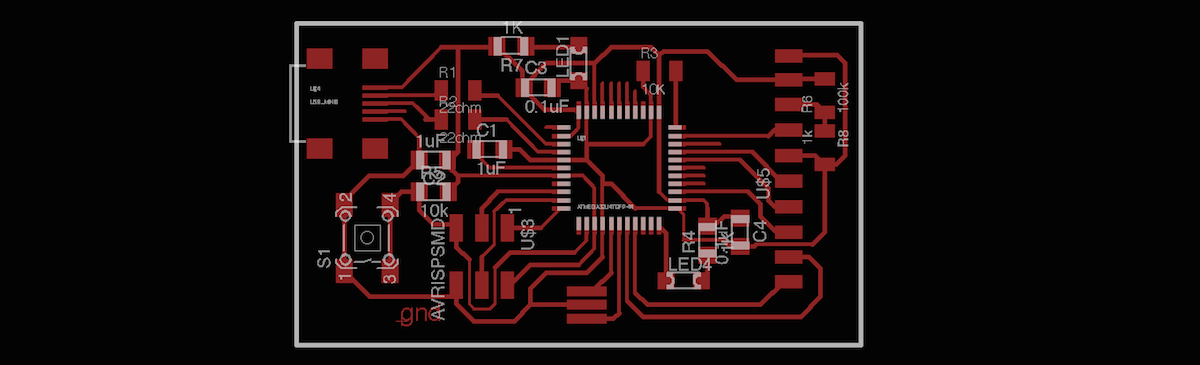

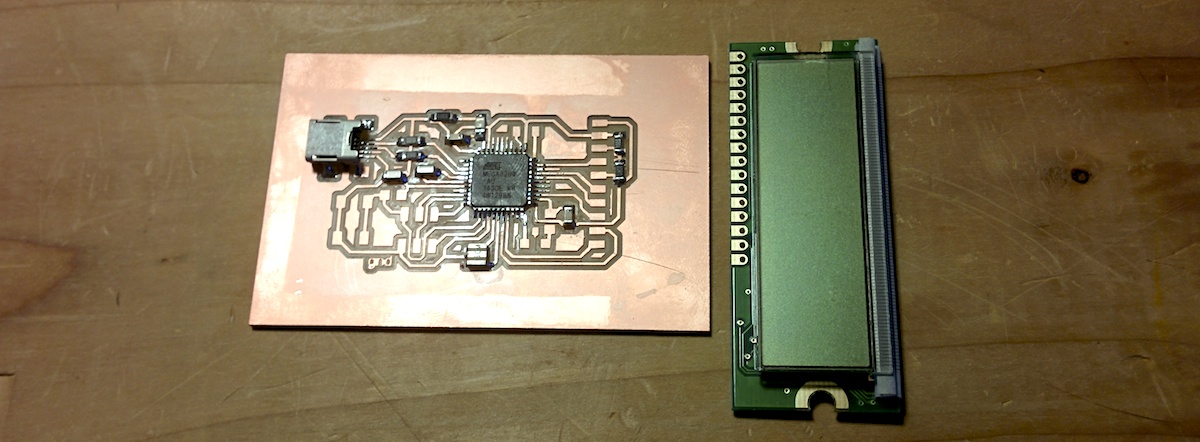

and the second is a lcd board driven by a atmega32u4

Here it is with the LCD:

Milling woes

Milling that 32u4 board was difficult because traces would keep peeling. It took 6 tries to get a board with one peeled trace.

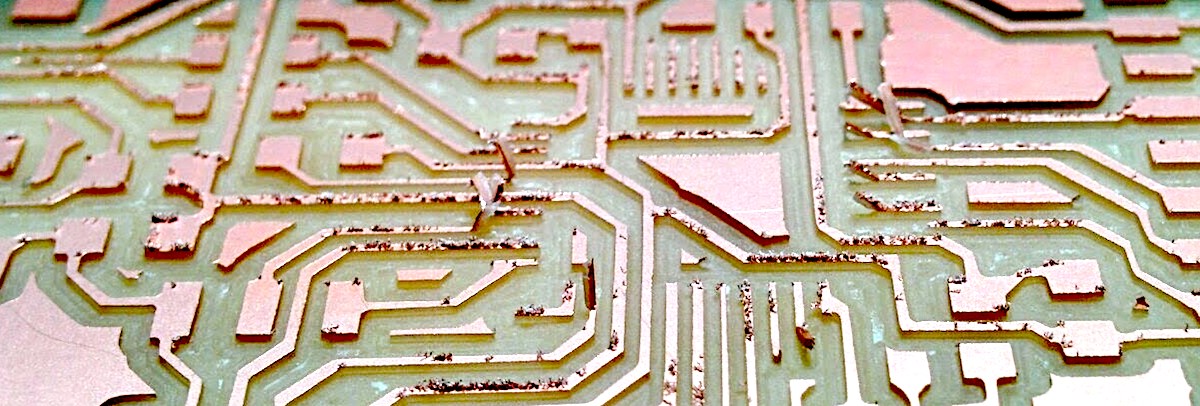

Here is an example:

Worth noting that I am milling with the end mill diameter set to 0.33mm when it is really 0.4mm.

I redid the pads for the TQFP44 package with smd pad size set to 0.06 x 0.012. This combined with a trace width of 0.3048 will let a 0.4mm end mill cleanly mill out the TQFP44 package. After this, I could get a non-peely board although it might have been coincidence.

Other advice I got about preventing peeling:

- lower speed (dan)

- cut at shallower depth (laura)

- use fresh end-mill but not too fresh. (jb)

- use different batch of boards ie board is problematic (neil)