Week 5: Circuit Design

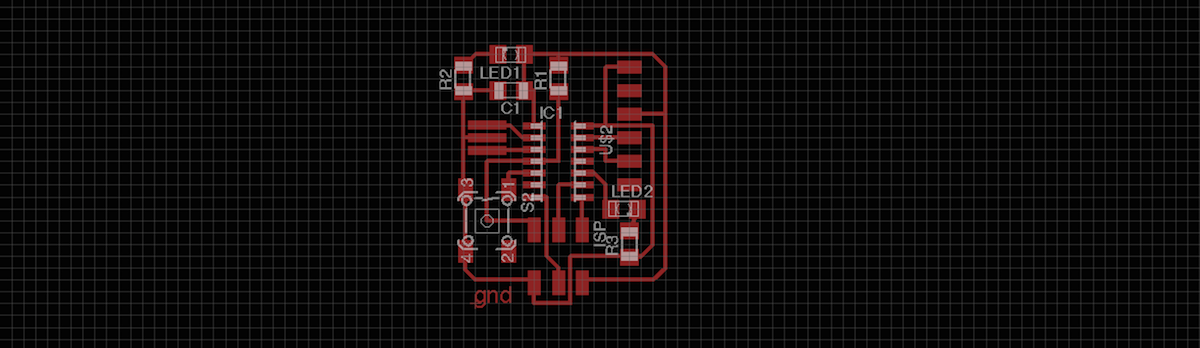

We had to design a hello world board (blink LED). The main goal is to learn to do circuit layout. I used Eagle although KiCAD was tempting.

In a break from previous weeks, instead of writing a journal, I will create checklists as I am going along. Will be easier for you

Schematic

- First draw on paper

- Use standard/LED library to get LED

- Use standard/supply1.lbr library to get VCC, GND

- Rest of the part from fab.lbr

- Use named nets for readability

- keep conceptually separate circuits separate in the schematic (eg. don't wire switch and led circuit together) (from Jeff D)

Board Layout

- Drawing traces should be newspaper puzzles.

- Rotating a component in Eagle is not obvious. Click to select and then right click. (right click without selecting opens a context menu)

- First lay everything out with a lot of space and then shrink

- protip: to check if you are done, hit ratsnest to see if there are any airwires left

- Avoid right angle traces (from Jeff D). Can reflect high frequency signal. Also bad mechanically.

Exporting

- Redraw the dimension layer using wire so it snug around the board

- Drag the fainter gray outline (board dimension) so it it is close to the dimension outline

- In the command bar:

display none topshows only the traces display top tNames dimension tPlace tDocugives traces, name, outline and placement + component outline- Use

display none topand then export PNG with 600 dpi for traces display none dimensionand then export PNG with 600 dpi for outline cut- Use gimp to invert and fill out the outline cut image so it is white on the outside all the way to the edge and black in the middle

- You can also use gimp for adding some flare to the image. I just added round corners because.

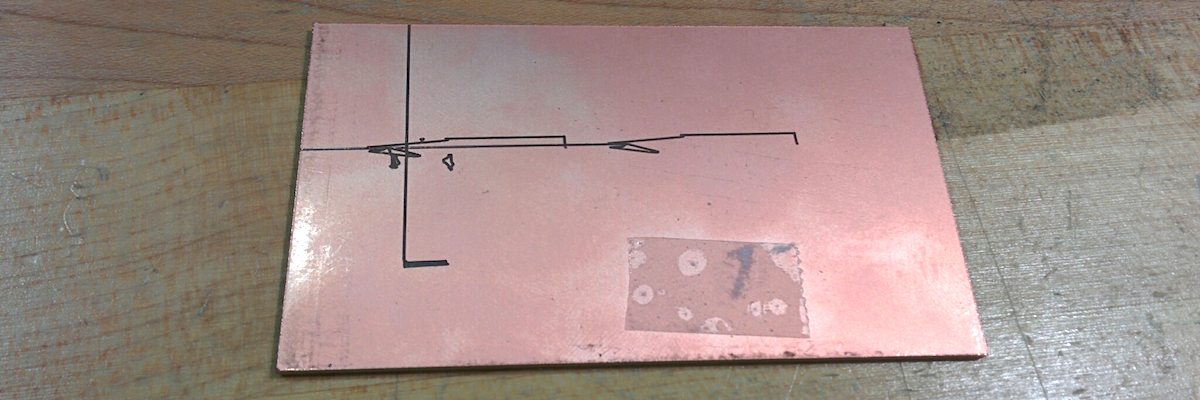

Milling

On Roland Modela

- put in view mode

- tape down FR1 board on top of sacrificial layer

- change end mill to 1/64 for traces 1/32 for outline

- unscrew two screws on the shank

- chnage mill

- zero end mill

- use move to xmin, ymin to get to a corner of the board

- lower end mill with up / down button on modela until it is close to the board

- unscrew end mill

- hold end mill in hand and lower head a bit more (shank will spin while you hold end mill)

- lower end mill by hand and it touches the board

- hold it down while you screw the two screws back in

- this is now 0 Z

On the computer

- make sure mod_server is running

- make sure settings for talking to modela is correct (on modela-1 ttyS0 9600 rts cts)

- calculate path

- verify path by inspection

- hit send

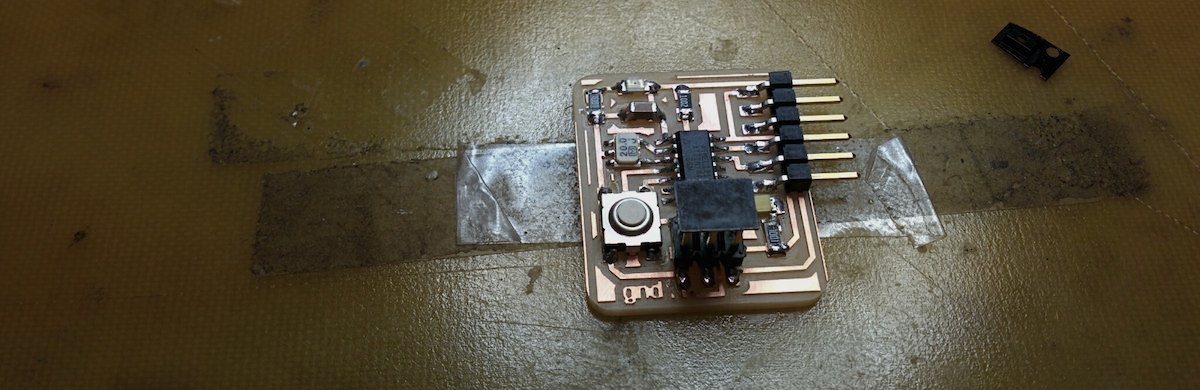

Stuffing

- Start from inside out

- Start from the shortest component

- Use a blob of solder to hold component in place

- Solder other ends of component

- Resolder the holding end

Things that went wrong (tm)

- After I milled a board I found out that the bit must have been dull. produced a board with furry traces

- Fab modules errored out with WebGL not supported. As a work around, I used a different computer to compute the tool path and then copied over the rml file and ran mod_serial.py from command line to push the path to the tool. Advice from mike: clear cache

- The flow control for the serial communication to the mill wasn't set correctly (rtscts) which sometimes caused the millhead to wander off and kill the board

- Picked the wrong registers for soldering. cf register codes