I wanted to cast and mold something with curved edges and surfaces, so I decided to make a small artist's palette as my final product. Using a reference sketch picture, I designed the palette positive in SOLIDWORKS.

Woo CAD.

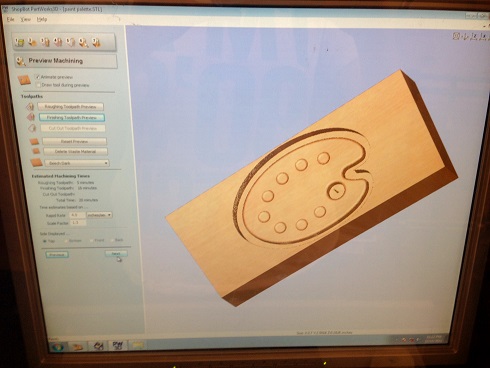

I exported the .stl file from SOLIDWORKS and used 3D Partworks to make the toolpath for the Shopbot, saving both the rough and finishing toolpath as one path due to the small size of the part.

The toopath preview.

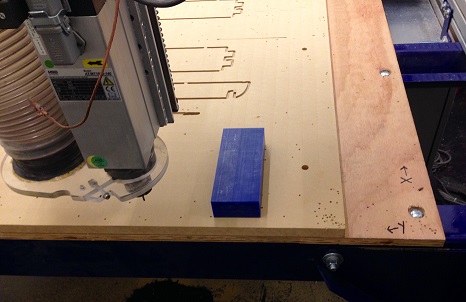

I then set up the Shopbot with an 1/8" ball-endmill, used hot glue to secure a 7"x3"x1" piece of machinable wax to the toolbed, and began to preview the cut.

Getting set up.

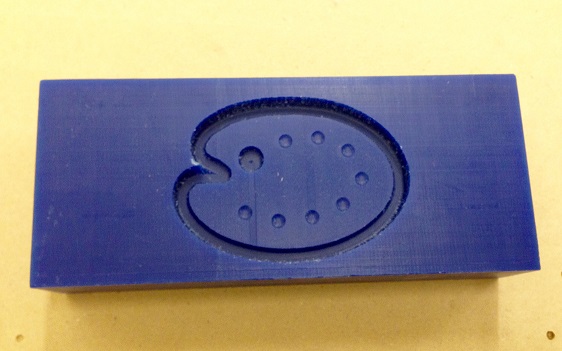

This took way more time than it should have, only because the default origin in 3D Partworks is the middle of the part. I spent about an hour just playing with origins and zeros to get the Shopbot to cut where I wanted. Once I had that figured out, the Shopbot machined the wax beautifully. I was impressed with the detail that I got from such a large machine.

Machined Wax!

I cast the mold using Oomoo 25 for its flexibility and quick cure time.

The Oomoo mold.

There was one air bubble near the edge of the mold that I was worried about, but I went ahead and cast the mold using a quick-curing hard plastic and didn't have any distressing leaks.

Shiny.

When I unmolded the plastic, I was pretty happy with the results considering that it was a bit of a rush job.