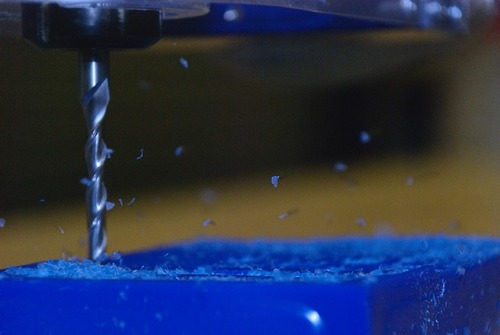

Machinable Wax. Photo from Invention Factory.

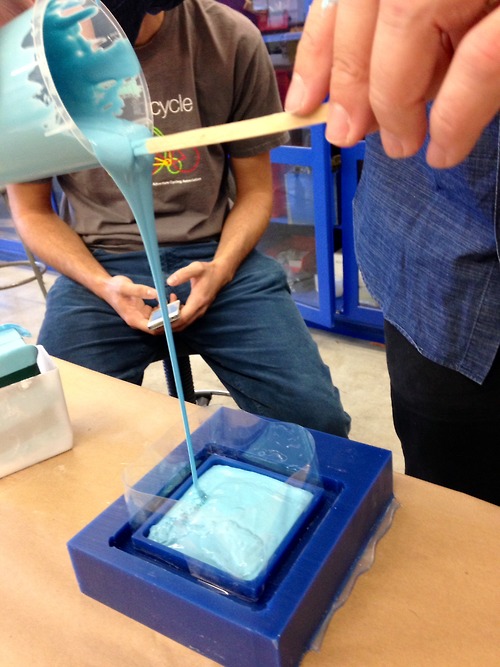

Jonathan pours sample flexible parent mold out of Oomoo. Tip: using the mixing stick to guide the pour cuts down on bubble formation. Note: clear tape is a great way to create additional wall height for an oomoo mold.

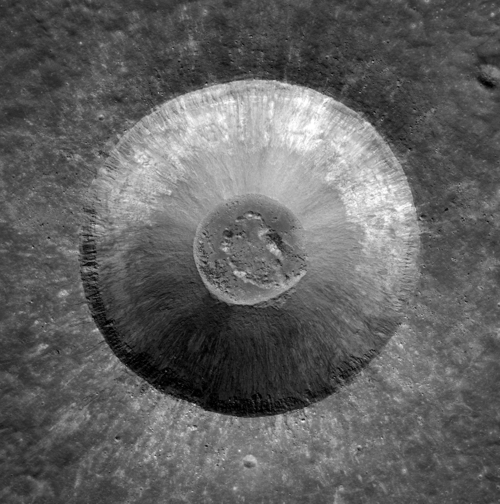

Moon Crater Photo of Lichtenburg B. Converted from .jpeg to .png in Photoshop.

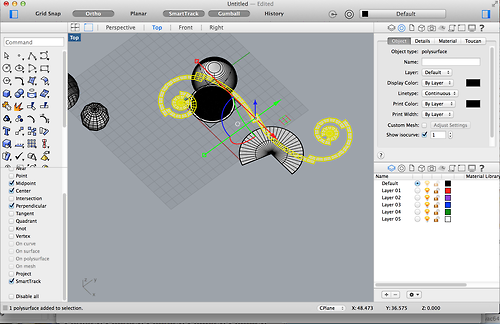

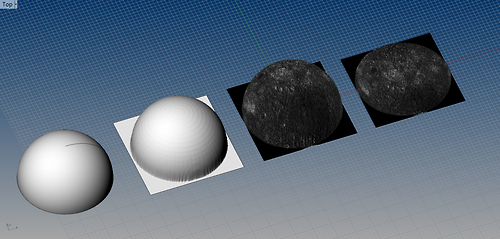

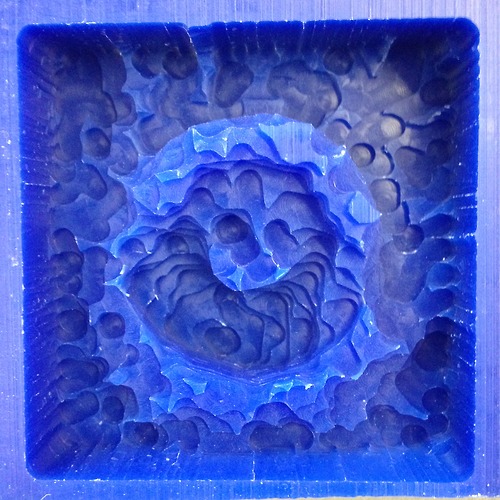

Here is the wax mold (positive) of the Fabmodule heightmap of crater photo. White in the photo reads as "high", black as "low." Milled on Modella w/ 1/8" endmill"

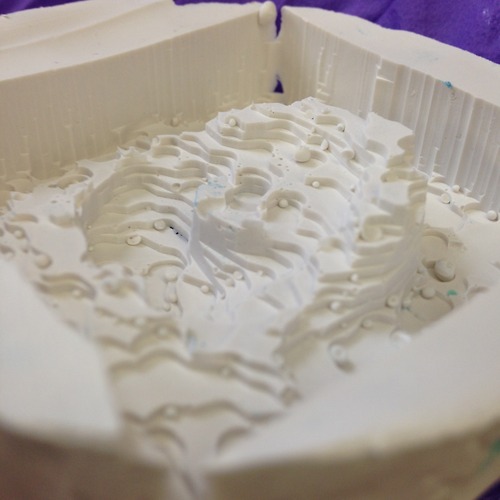

And here is the Oomoo (negative) mold.

Cast heightmap of crater in Drystone. Those aren't bubbles; they're moon stones. Okay, they're bubbles. I tried to cast the mold upside down. Bad idea, as there are no venting options for inevitable air bubbles.

Digging for air. I tried to create one by sealing the bottom of my casting situation, flipping it over and digging a hole out of the top. Complete butchery! Messy fun.

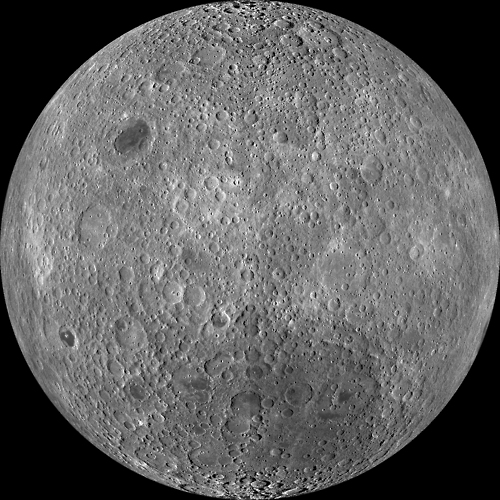

Farside of the Moon

Step 0: Get to know our moon

One of the coolest outcomes of this week has been getting to know our moon. When I was casting about for ideas, I found Joseph Morrow's Cast of the Gale Crater (from HTM 2011). I started pouring through photographs of our moon. I realized I'd never seen a photo of the farside of our moon. I imagined making a 2-part cast of our moon using topo data - how cool it would be to hold the moon in your hand and study the far side just by turning it over; we could rotate the moon in our hand and see it turn, something gravitational tug of war never let's us see.

Nearside of the moon