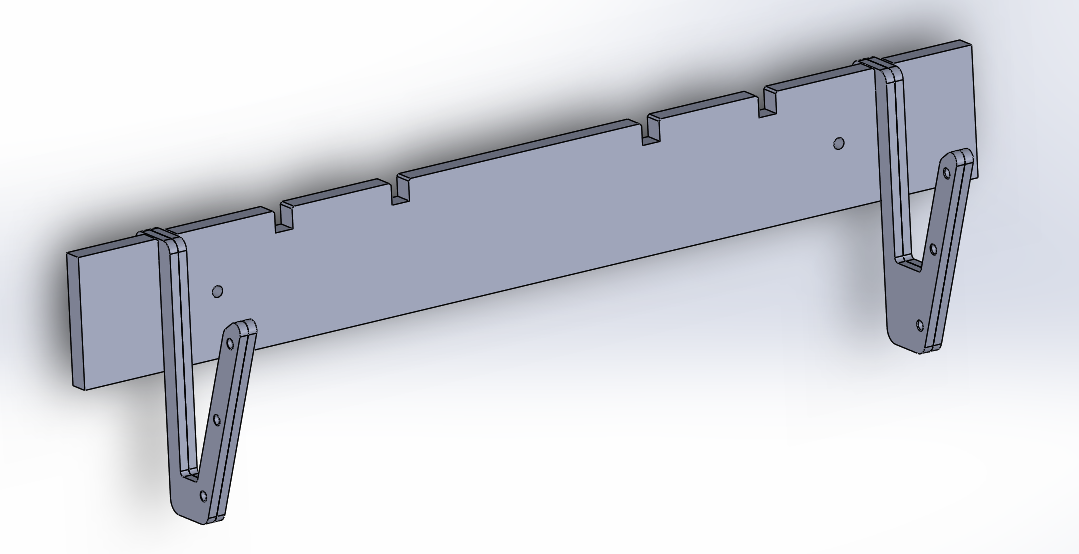

For this assignment, I created a mounting rack for my longboard. This rack consists of an acryllic back and two acryllic hooks that can be press fit into several locations on the back to accommodate boards of different lengths. There are two circular pieces of MDF that are used to space the rack away from the wall for mounting. All pieces (acryllic and MDF) are nominally .5". I designed the rack in Solidworks and exported DXF files to the laser cutter to fabricate each piece.

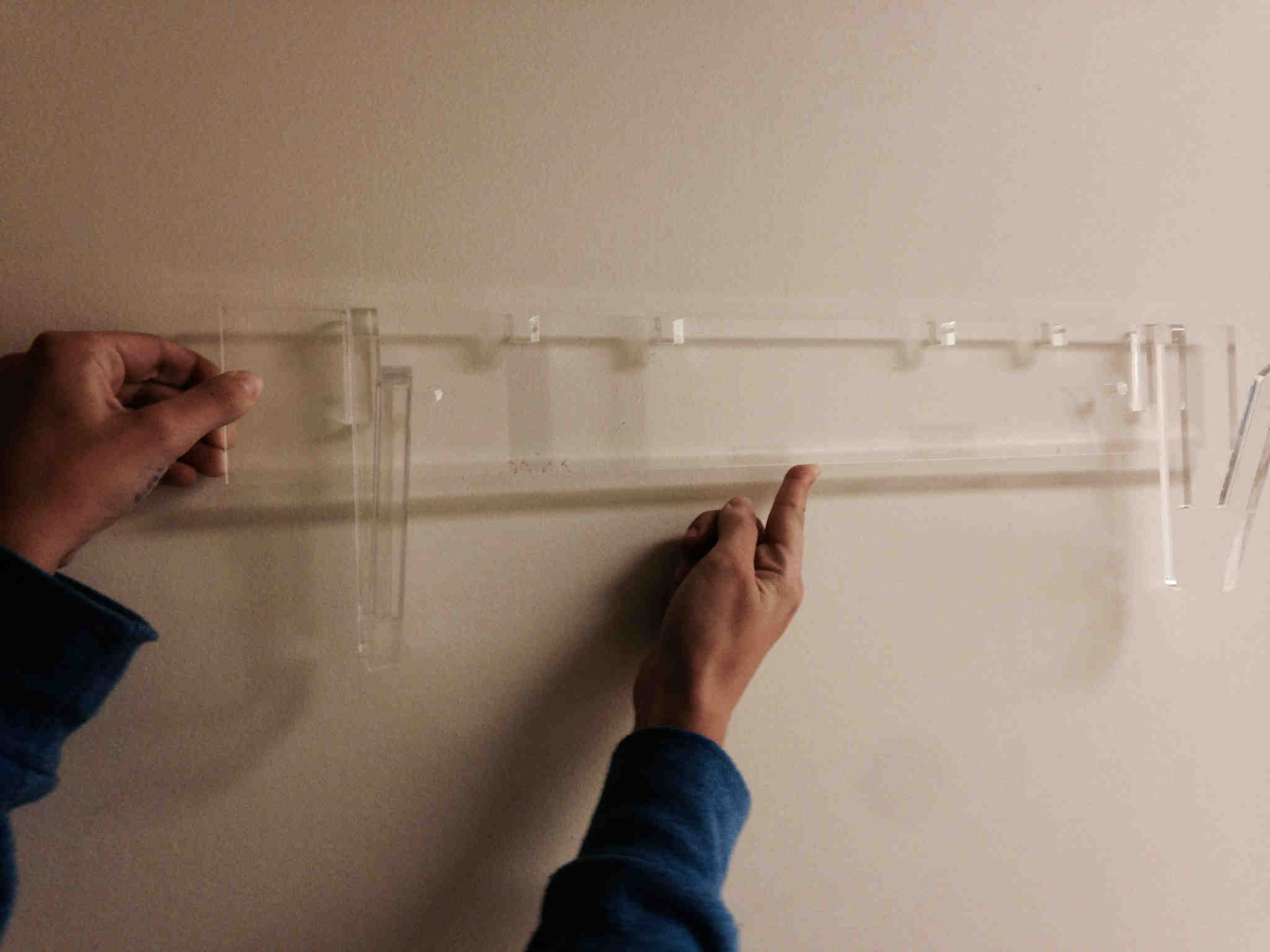

As seen in the Solidworks assembly below, I originally designed each hook to be made of two thinner acryllic pieces that would be connected by several metal studs. I liked the look of this better -- I thought it added a little detail/interest to the rack. For that reason, I also cut some small lengths of .25" steel tubing on the band saw to use as studs. When I went to snap the assembly together, however, the thin acryllic proved too brittle and broke into a bunch of pieces. I eventually decided to make the hooks out of the same material as the back, but this meant I had to refigure all of my press fits (adjusting the Solidworks models and cutting test pieces until they fit correctly).

After assembling the whole thing, it feels way too brittle. You can also see in the Side View picture above that the hooks are bending quite a bit under the weight of the board. I think this will break if I try to use it for very long. I think I will need to make this thing again using a different material (probably wood) and a different process (maybe CNC routing).

Home