Burlap didn't really seem like a pretty material, and I didn't really know what I wanted to make out of composites. However, I remembered that someone mentioned the idea of making a briefcase in class. I googled around for shell briefcases and found some nice images:

Brown rough material, simple design; check, check. I made a little model in Rhino with my initials engraved on one of the sides.

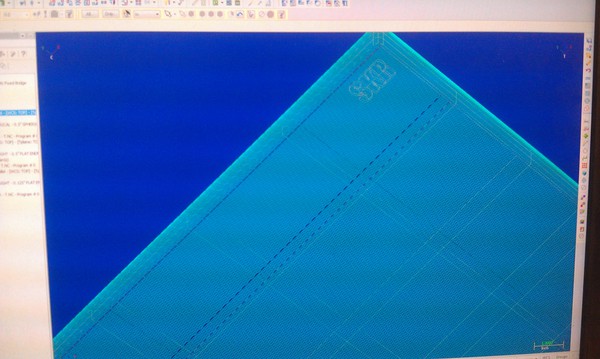

I went to the architecture wood shop, and after some work, helped extensively by Austin, made a MasterCAM file. (I had to change the initials to use Impact font, since otherwise the thin parts of the "K" were too small for the Onsrud at any reasonable size of the engraving.)

The foam took an incredibly, amazingly long time to machine: almost 3 hours!!! The stepover size chosen in the MasterCAM file was simply far, far too small. It should have been a five minute job. In any case, the foam came out looking a bit hairy on the sides:

Also, I realized by the time it was cut out that the briefcase is a bit too big to be even remotely usable :-(

It took me about thirty minutes to sand all of the hair off. I found that it was important to be very gentle and consistent with the strokes of the sandpaper, since otherwise a misplaced stroke could damage the foam. It looked fairly nice by the end, however.

Sadly, by the time I got to the RPL, there was only one more run of the vacuum bag setup left, and since my molds were so big, I wasn't able to fit them into the bag (given that other people were in line in front of me). In addition, I realized that the letters are too small to really be noticeable when you cover the whole mold with burlap. Hopefully, I'll be able to finish the process sometime in the next few days; although I may design a new mold tomorrow based on what I learned from seeing how other people's casts came out.