Step 1: The phone!

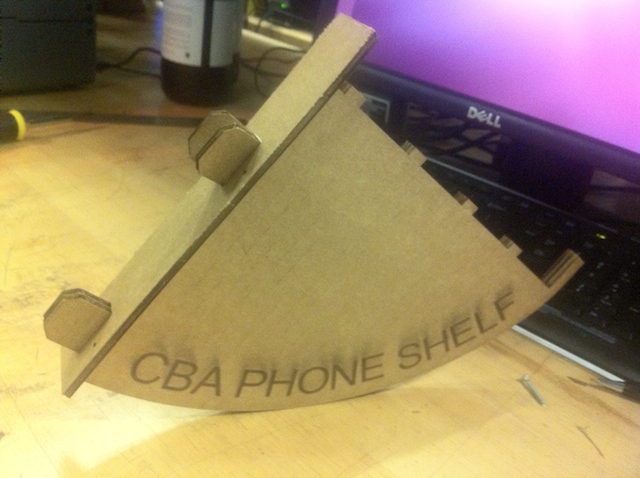

This week's assignement was to create a press-fit construction kit, using the laser-cutter. I decided to create a shelf to mount the lab phone in E15-015, which turned out to be both fun and useful!

Firstly, I calculated the dimensions of the shelf, consulting the datasheet of the Polycom IP550 phone.