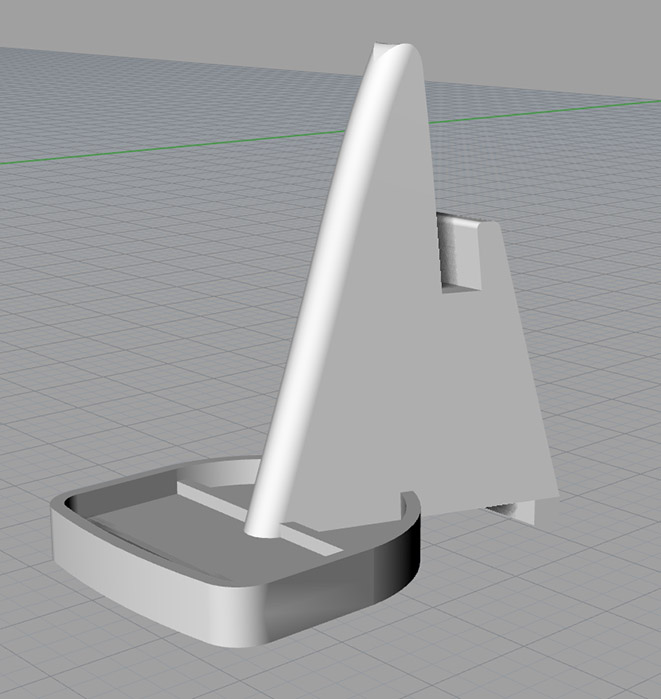

For the 3D printing portion of the assignment, I wanted to design something useful that I can put on my desk. I always lose my glasses and my contacts, so I decided to design a nose-esque stand for them.

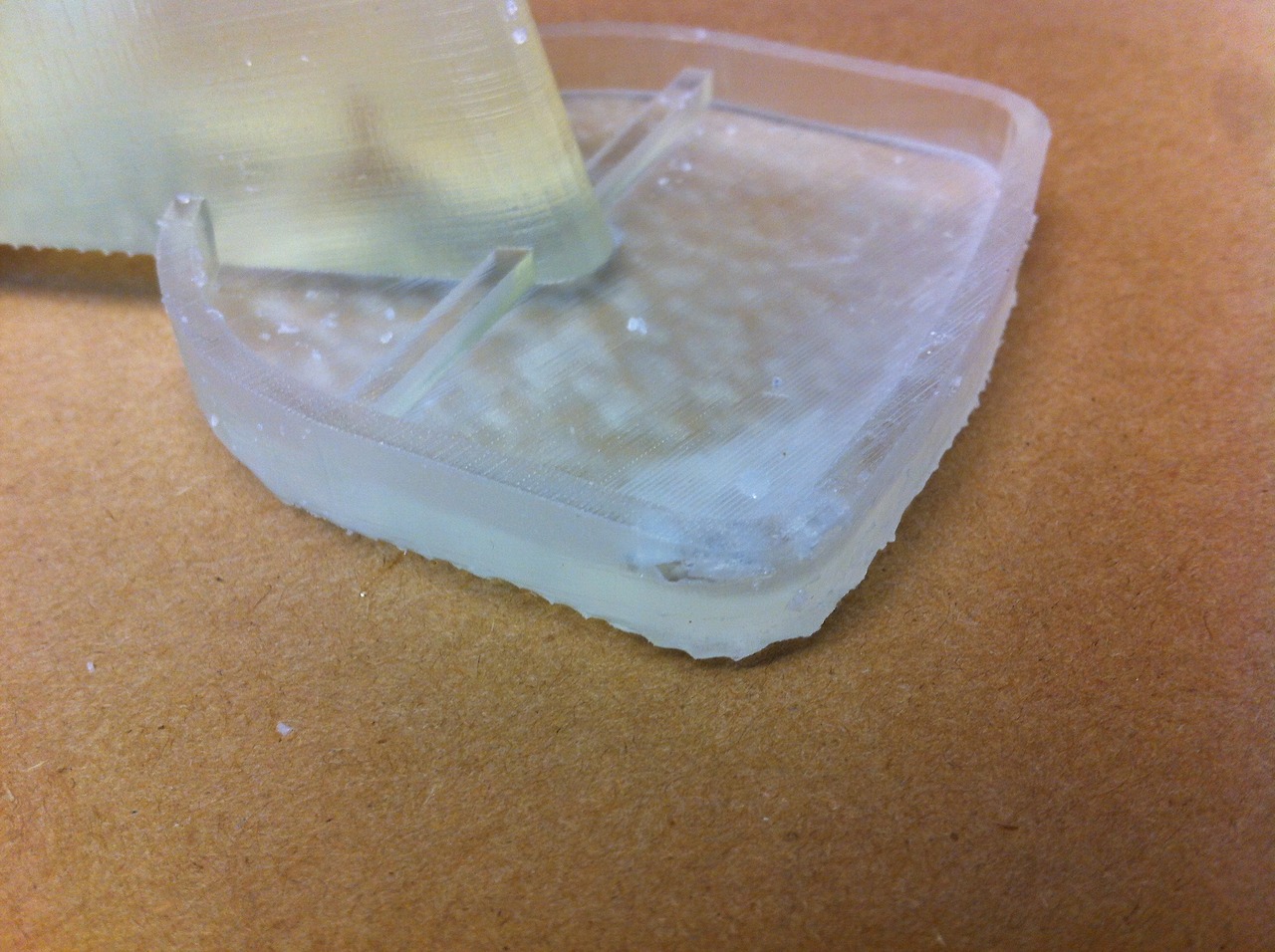

The design was made in Rhino and I went back and forth from measuring my glasses and drawing by hand and modeling on the computer.

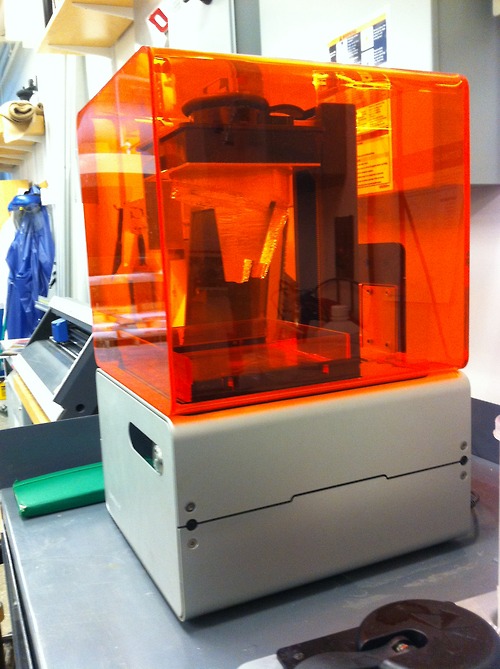

Once the file was finished, I exported it as an STL and submitted it to be printed on the the formlabs.

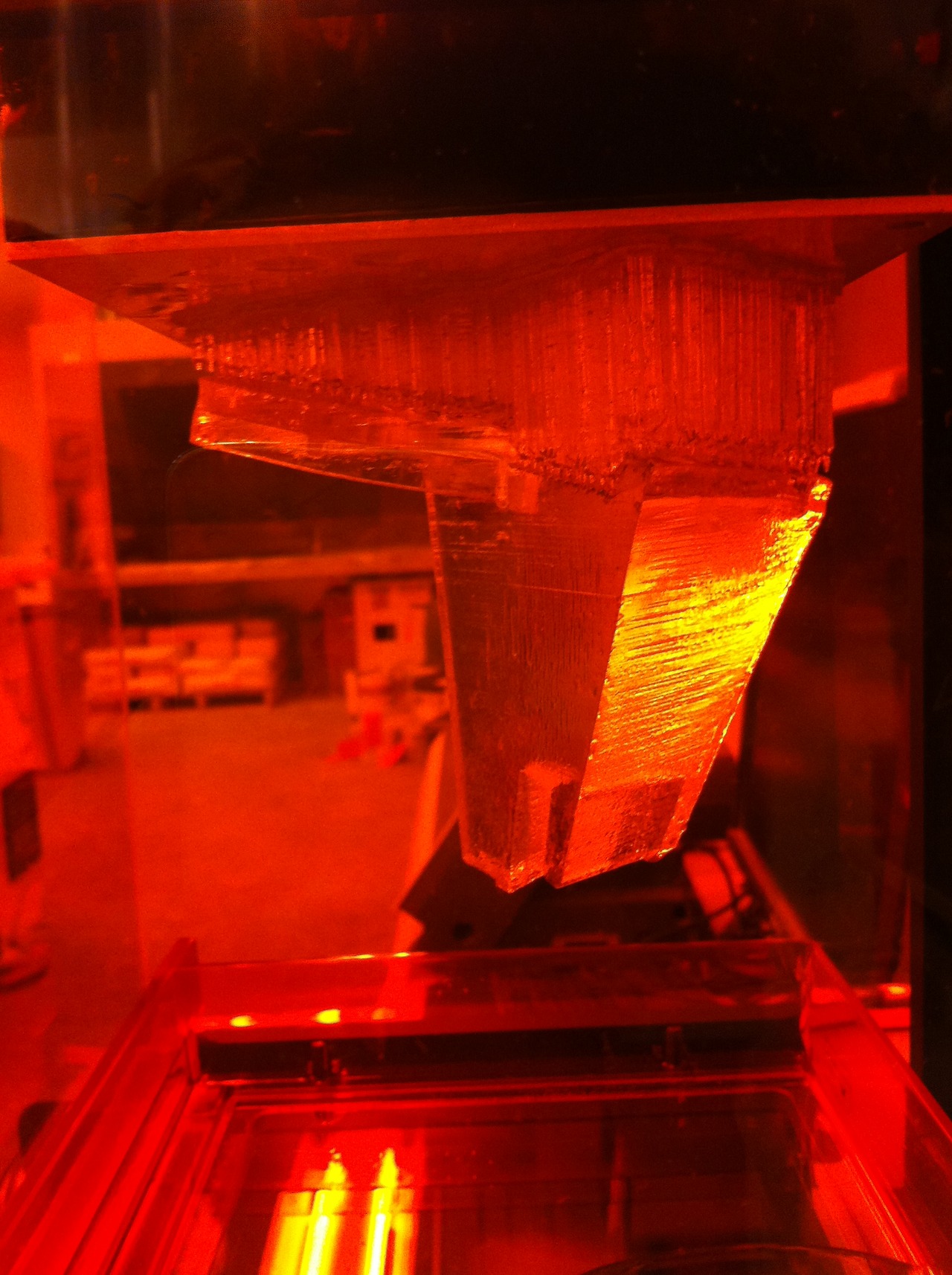

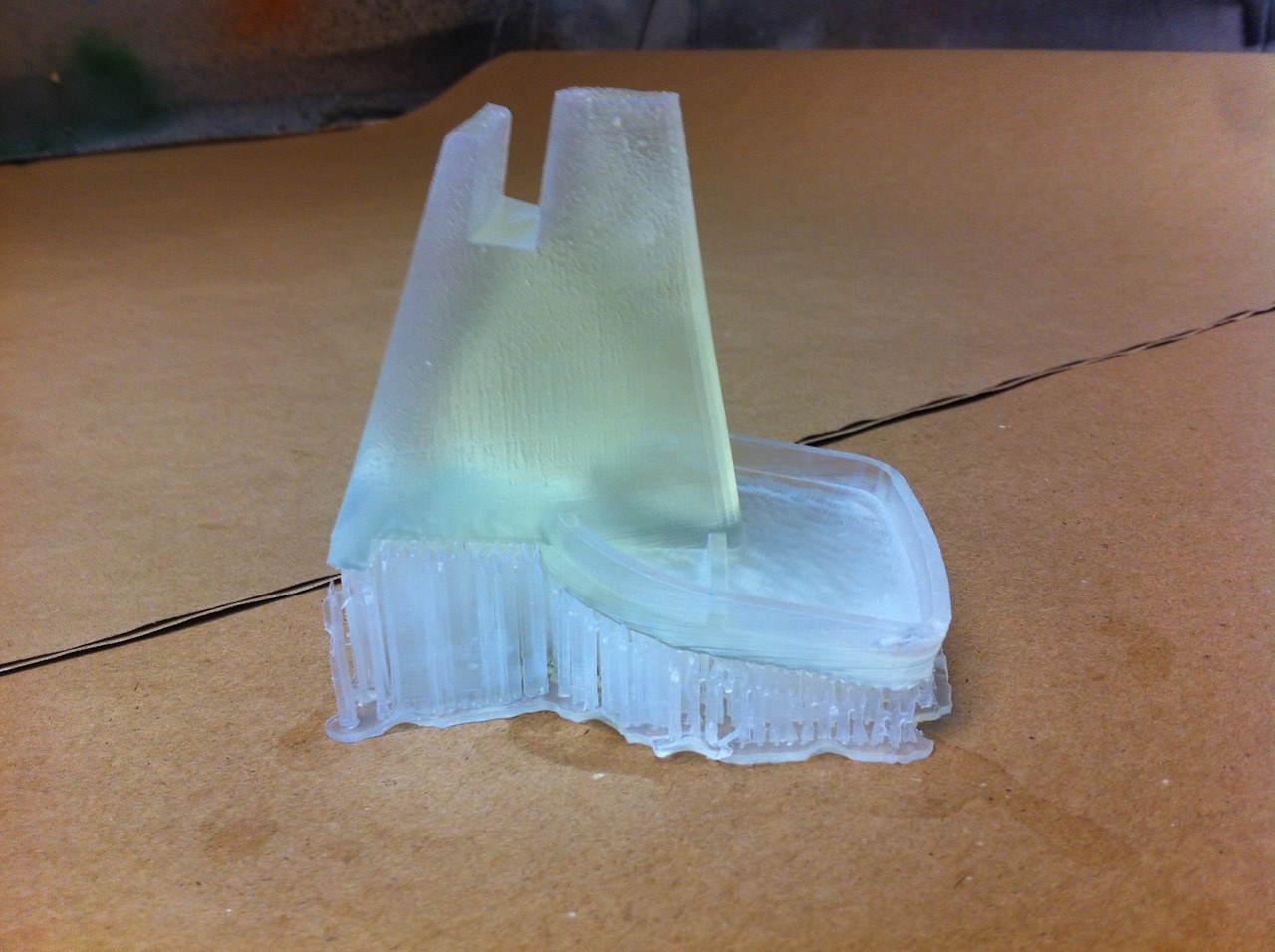

For some reason, when I came to pick up my print I saw that the top did not print (or had melted off- there was a puddle underneath it and it seemed to be dripping...strange.

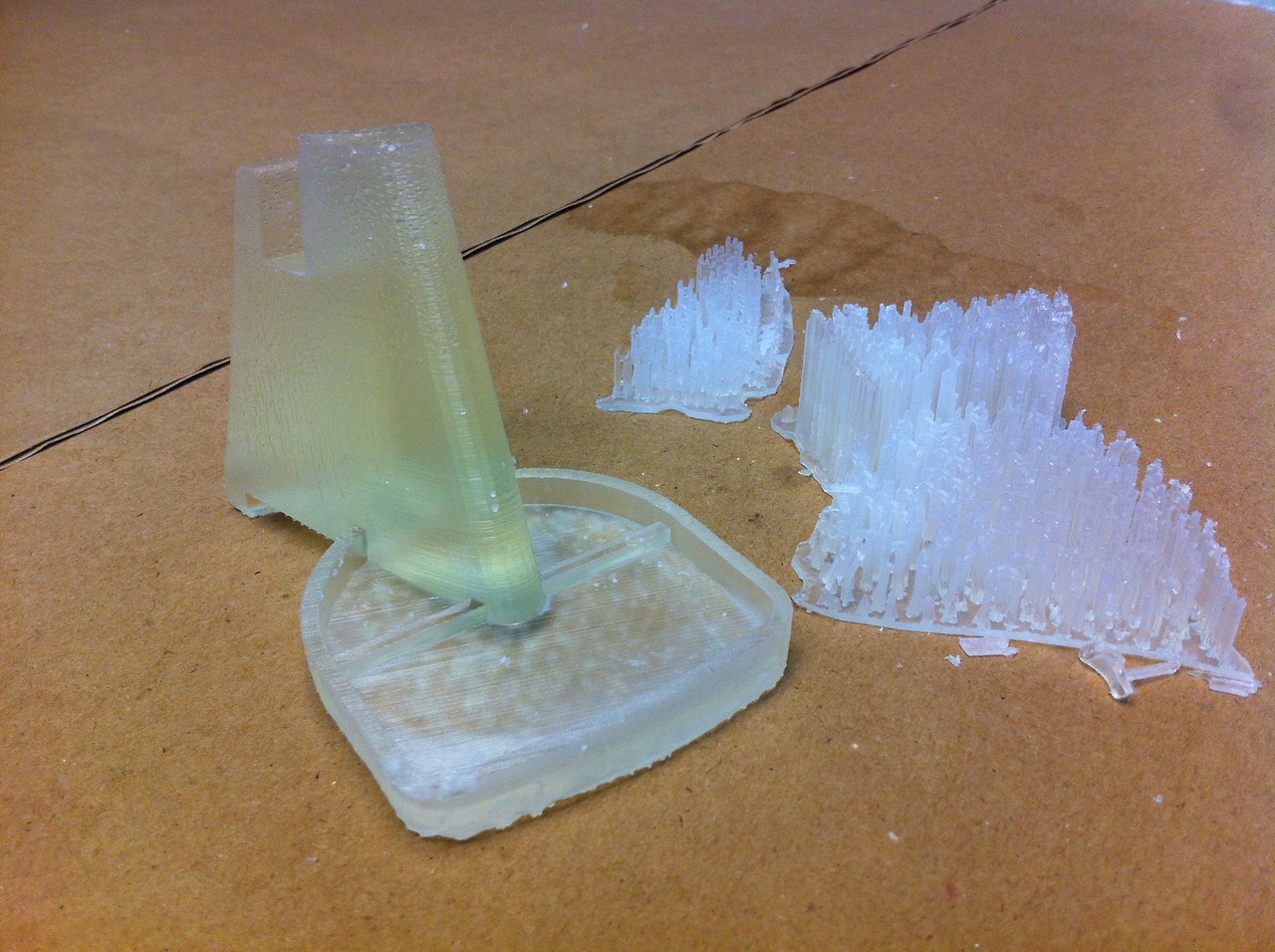

I put my print in the rinse tub and then removed all of the flush (at least I think thatís what all that extra material is called..)

It wasnít a super clean finish, and in retrospect I could have printed a better version with different material, but I really wanted to try out the formlabs since I have used the other RPL printers before.

I canít say I know too much about 3D printing coming out of this since the operation of the actual printer was done by shop TAs (as is the way of the architecture shops). If I have more time in future weeks Iíd like to try out the makerbot!

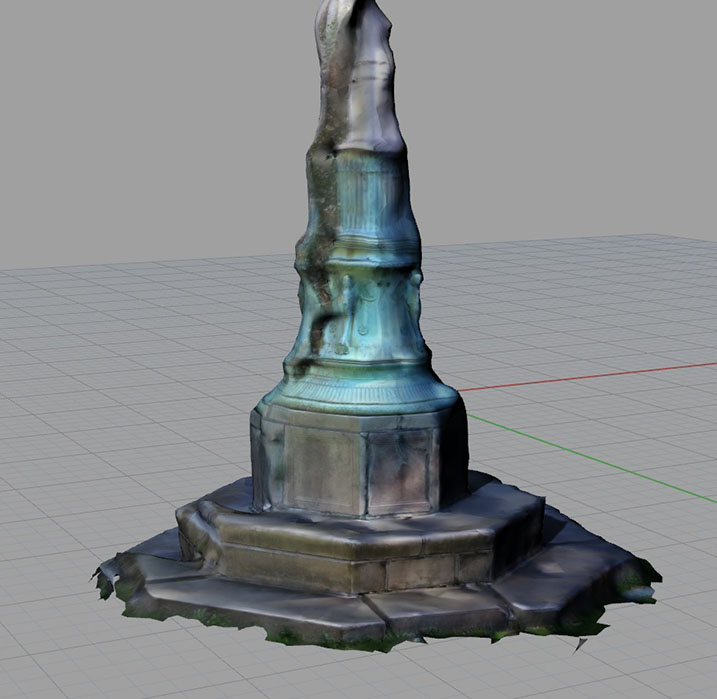

For the 3D scanning portion of the project I used 123D catch, which took a series of photos and turned it into a 3D model. I thought this was a super cool way of getting a model, as I could use something as simple as my phone.

I wanted to try out an architectural project, so I went to Killian and photographed the elaborate base of the flag pole.

The model was rough but relatively accurate! I cleaned up some of the surfaces in 123D Catch and then exported it into Rhino.