Making Machines

Group Project!

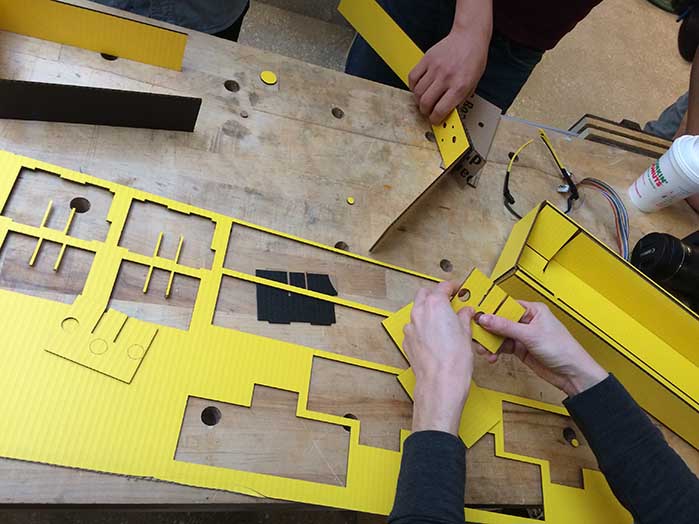

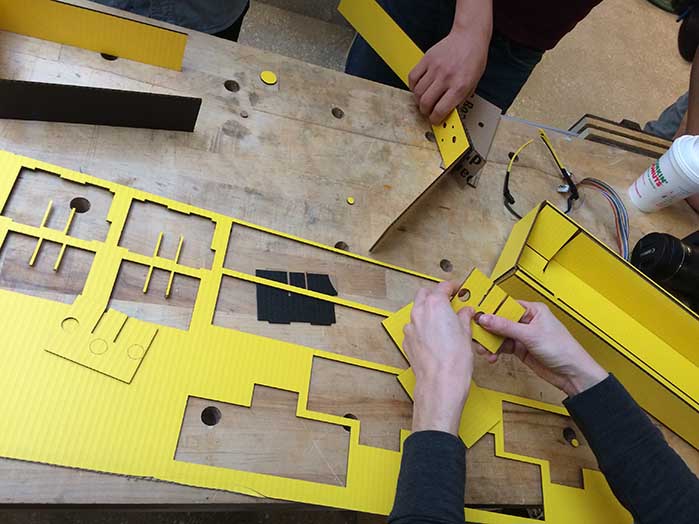

Machine week started off with a session with James and Nadya + the whole central section. We fabricated the linear actuators for our “machine” as a team (with a pretty neat cardboard kit that Nadya and James designed) and then were left to brainstorm.

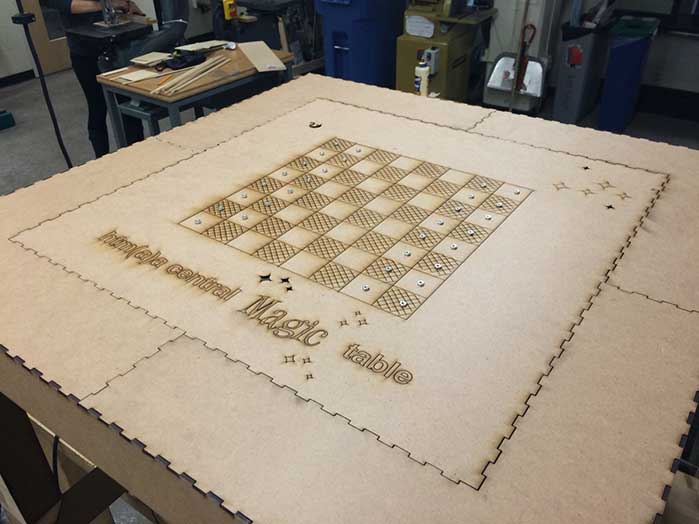

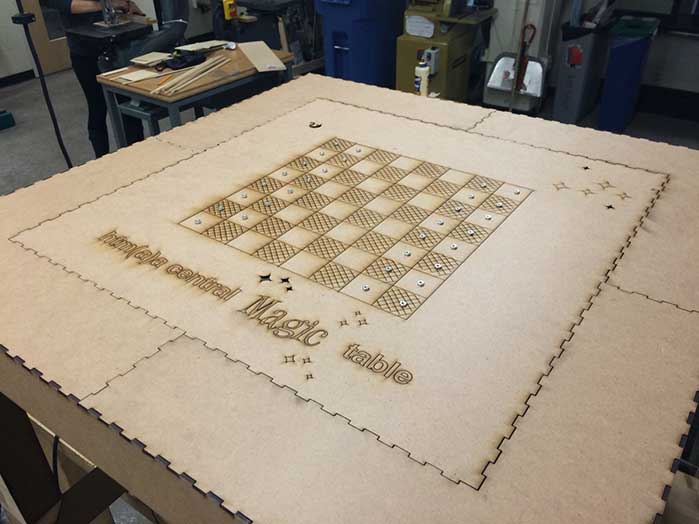

We decided on the idea of some sort of “magic table,” where a magnet could be moved around under a table surface to move objects on top of the table. We thought a great implementation of this would be a chess game, where you would play chess on the computer and the pieces would move on the table.

Some logistical issues included how to only have the magnet attract one piece at a time, how pieces would “die” or “kill” other pieces, and how to implement all four actuators.

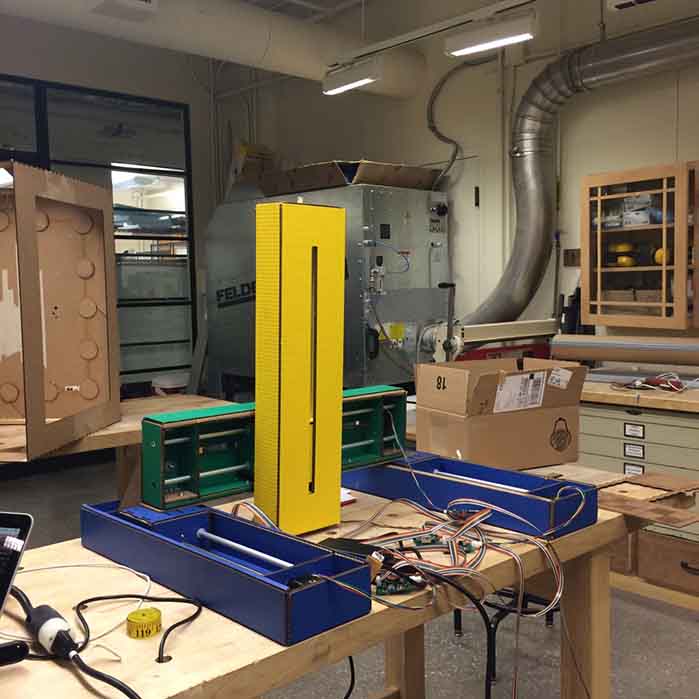

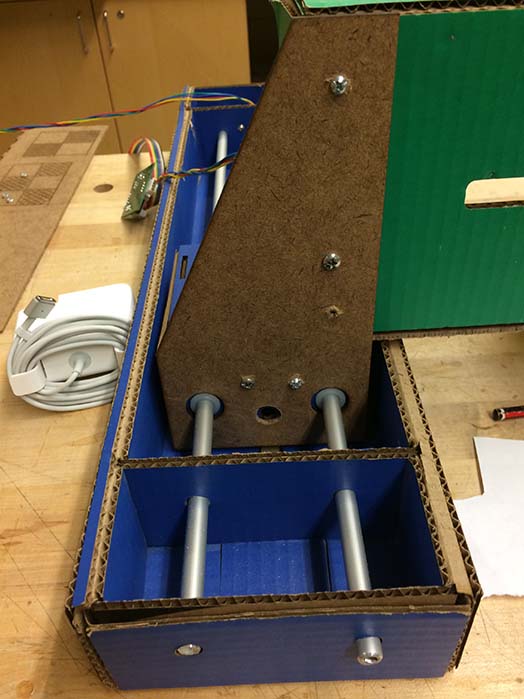

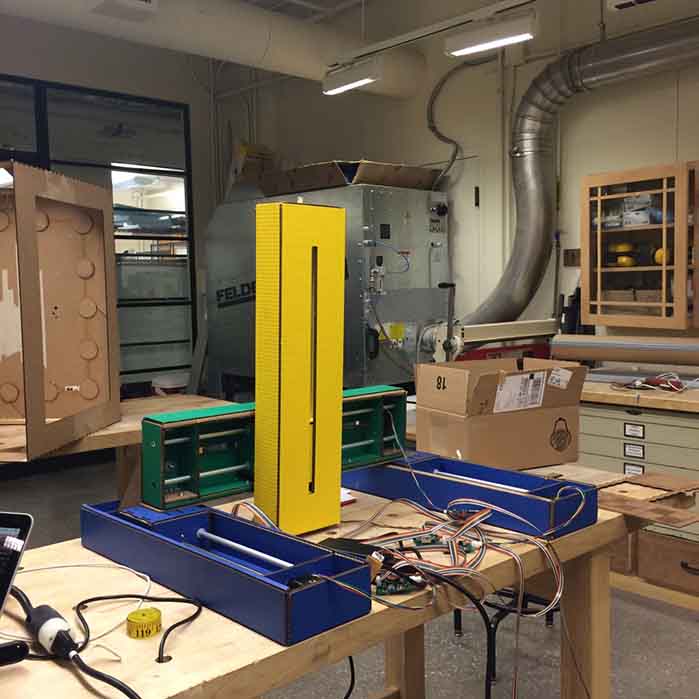

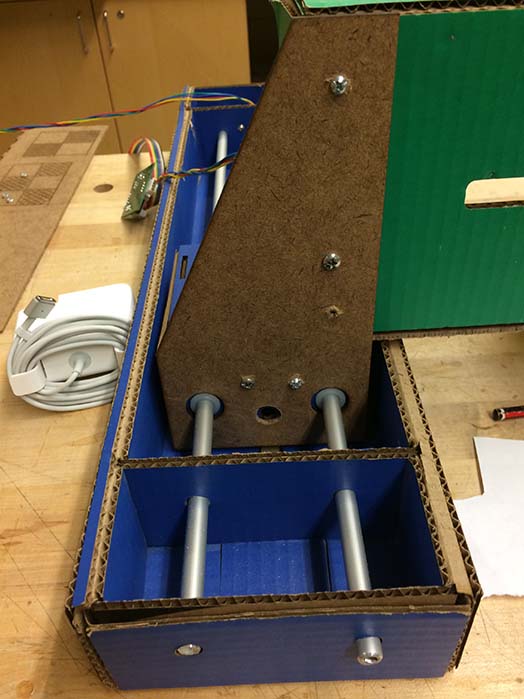

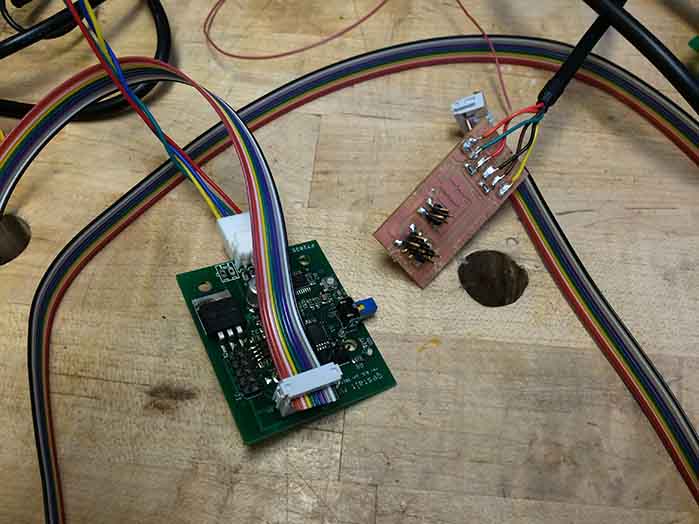

The final design consisted of two blue actuators controlling the x direction, and the other two controlling the x (green) and y (yellow). The actuators had to be connected to each other to allow for movement in the x, y, and z directions simultaneously. We found that the stiffness of the connections of the actuators was problematic due to the cardboard material. Extra holes were drilled and braces were added so that the material connecting the different axes was stronger. The most important joint was the x-y connection as the x-axis supports both the y and z drives.

We oriented the magnet on the side in order to attract only one piece at a time.

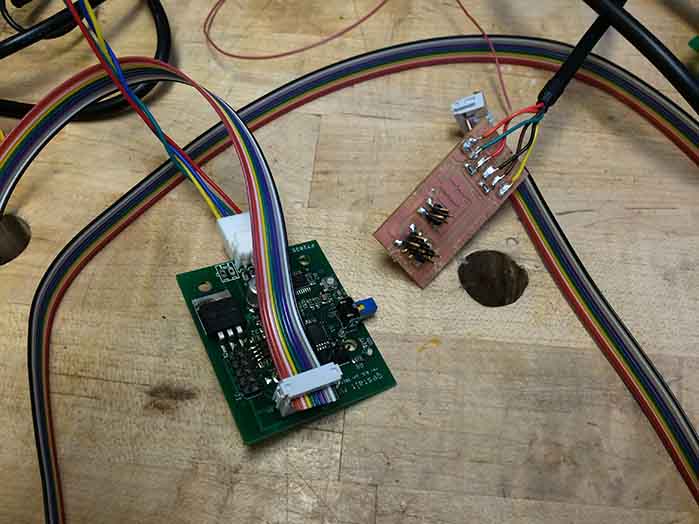

Many more hours of fabrication, troubleshooting, and bonding ensued.

Merev, Ines, Holly, Austin and I were the laser cutting team! This included the table, the board, the actuators, and the pieces. Assembly of these components were a team effort.

A chess board is 8 spaces by 8 spaces, so we decided to make each space 1.25 inches by 1.25 inches (making the spaces span 10 inches by 10 inches) and leave a half-inch perimeter around the spaces as storage for chess pieces that get "killed."

I designed the chess pieces (using pictures of Neil for the King, Nadya for the Queen, James for the Bishop, and other fun interpretations of chess pieces).

It took quite a bit longer to design the press-fit pieces than I thought it would, but they came out pretty sweet!

After some experimentation we found that the pieces were having trouble moving across the board because of the friction created by the “hashed” dark squares on the board. It did work with just the metal nuts though!

All in all I’d say it was a success! Check out our group page (central) for machine videos :)