This week we learned about composites and out assignment was to design and build a 3d mold and produce a fiber composites part in it. I chose to create a fruit bowl.

Final Result: (scroll down to find out how I screwed up)

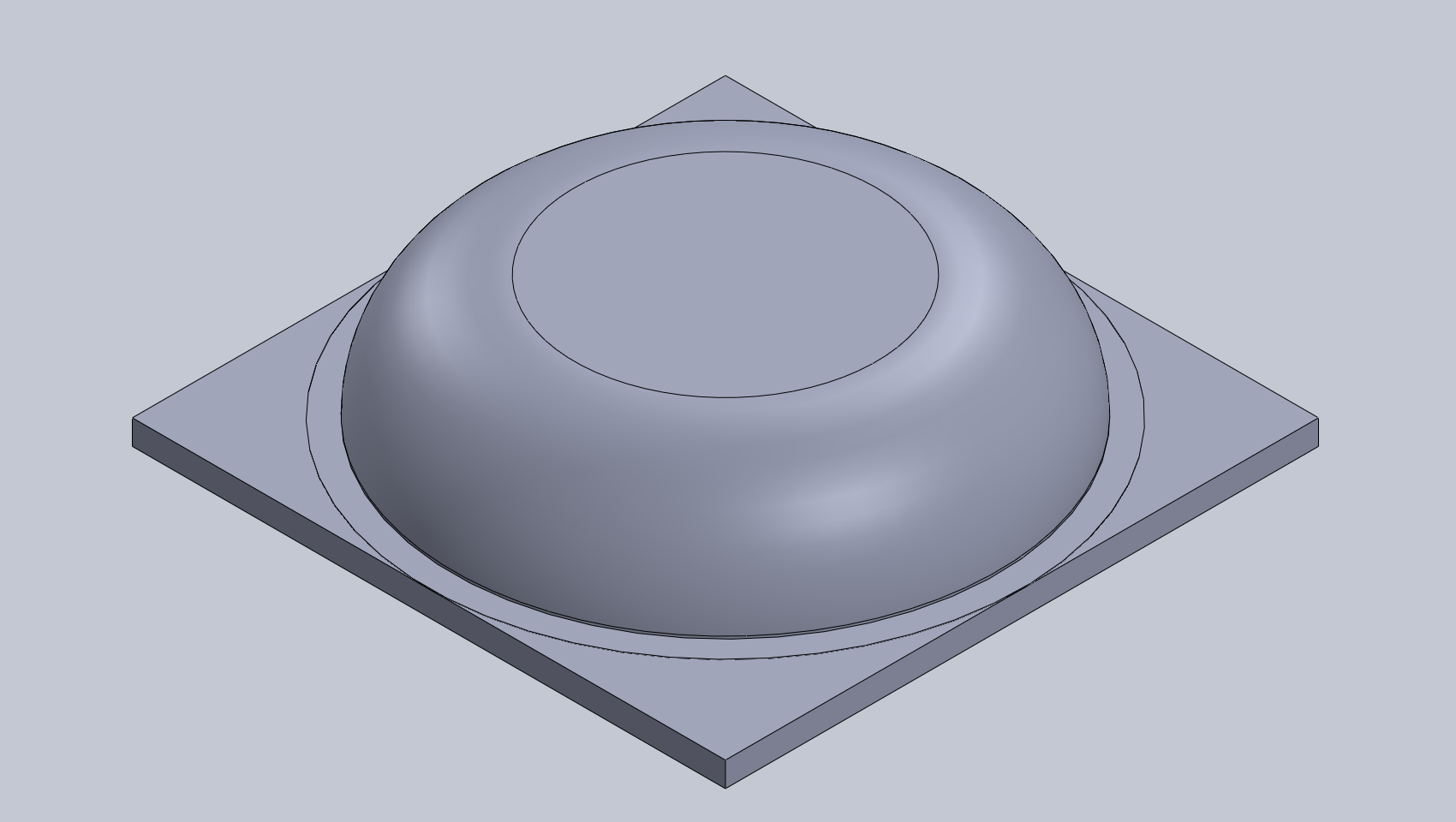

I created a negative in Solidworks

I used the shopboat to mill the negative in foam. I attached two pieces of foam using guerrilla glue and used a 0.5” ball nose cutter for the sake of speed.

Apparently I did not put enough pressure on the two pieces of foam and/or did not apply the glue evenly so it created a gap. As a quick fix I used clay. (thank you Sam for tip)

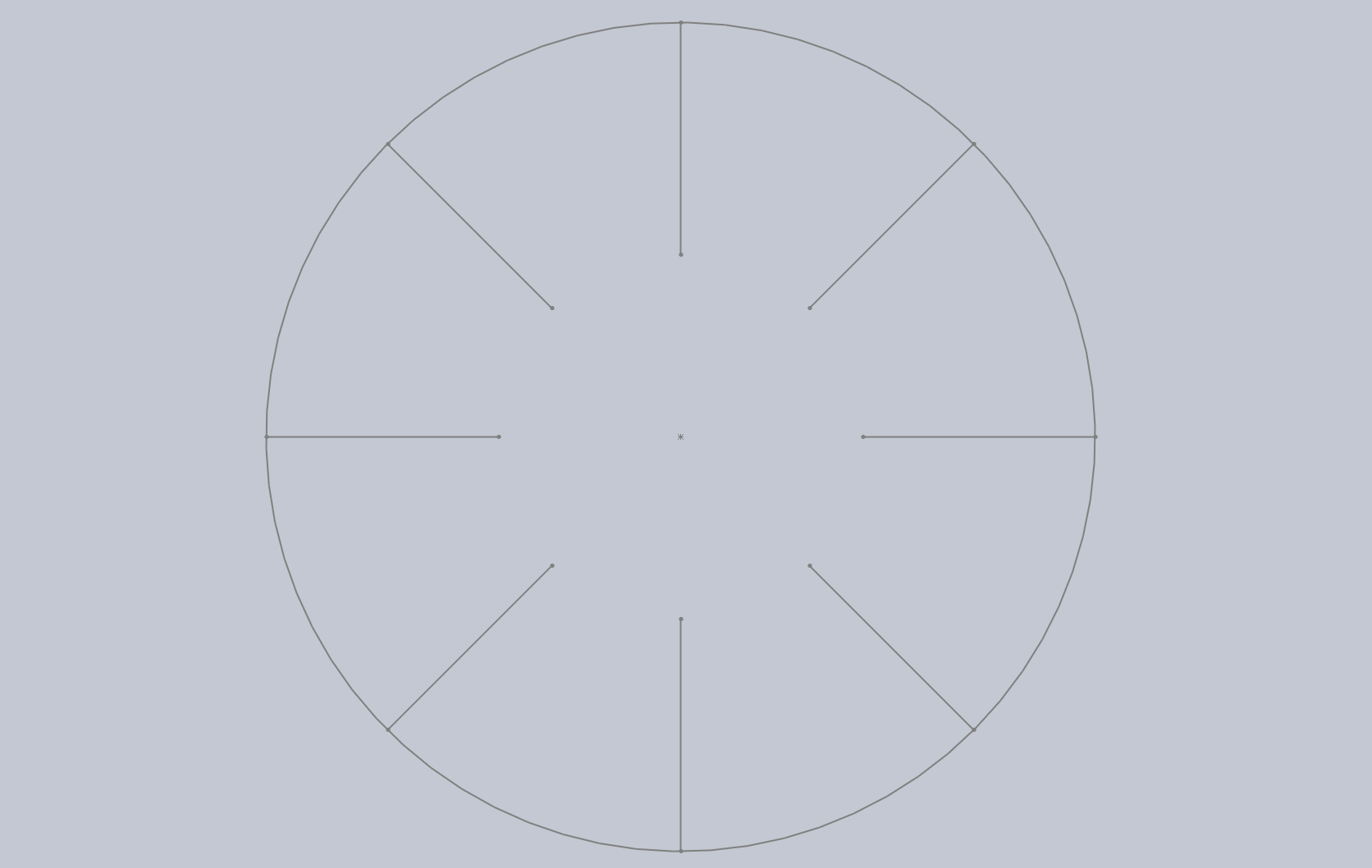

I designed and laser cut burlp pieces to match the size of my bowl.

The actual process of making the composite was too stressful and messy to actually take pictures of it. On the mold I put a release, 4 layers of burlap soaked in semi-clear epoxy, a bleeder (release with small holes) and a breather. I then entered the entire bulk into the vacuum bag and vacuumed for 3-4 minutes.

12 Hours later. Voila!

And like always, just to screwup the last bit, I tried to clean up the sides with a bend saw (yes, exactly)