Composites

Harvard Shield

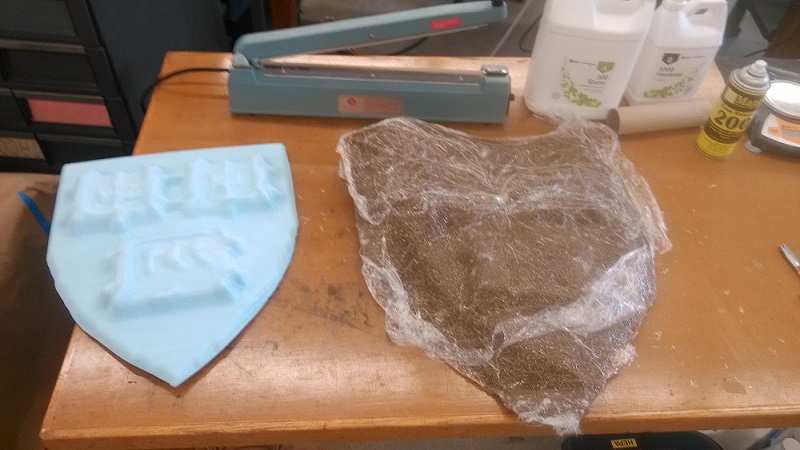

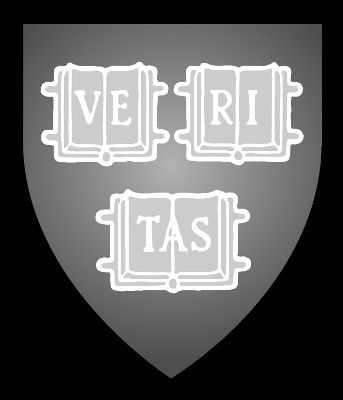

To make the mold, I converted a large image of the Harvard logo into a grayscale image, and then used the heightfield function in Rhino to make the STL model, as in Week 7. I started with a black background, and added a less dark shield face. I tried to get some concavity to the shield by using the circular gradient tool in Gimp. Then I added the three open books from the Harvard logo, being careful to change the black lines in the original logo (which would translate into troughs in the 3D model) into white lines.