Press Fit Construction Kit

This weeks assignment was to design and construct a Press Fit Construction Kit using the laser cutter. I initially wanted to make a fully parametric geodesic or a "fly's eye" dome, but after a couple hours of false starts decided to simplify things and make an icosahedron instead.

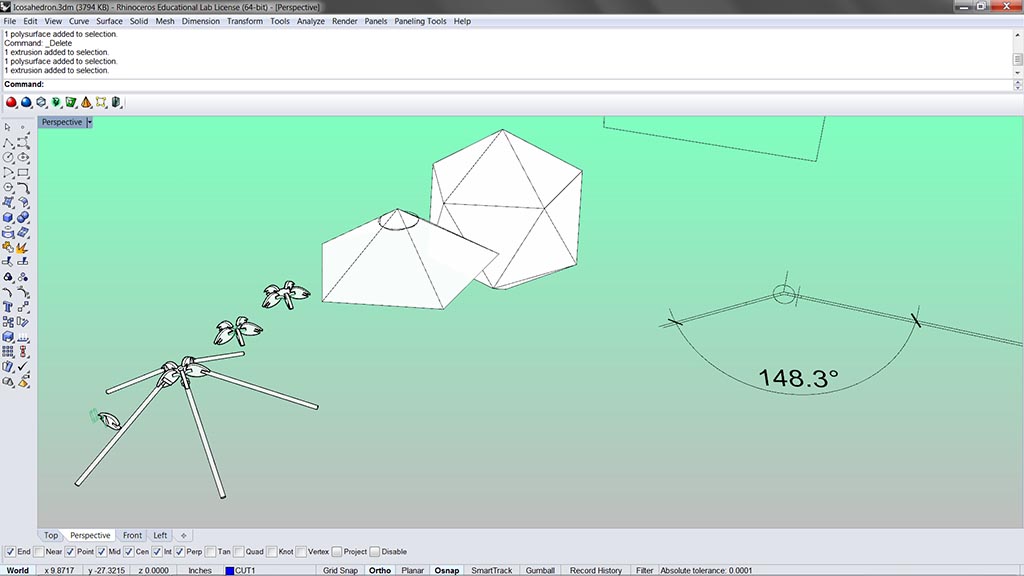

I started by modeling an icosahedron in Rhino and then extracted a couple of key measurements and characteristics from the primitive form.

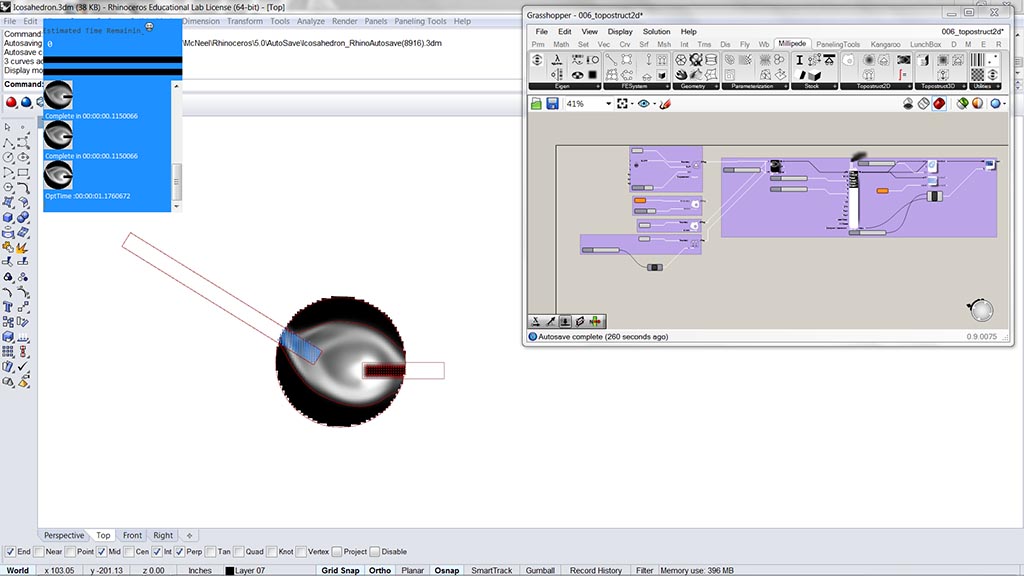

I modeled the joint condition in abstract and used a topology optimization proces in Millipede to get a general idea of the stresses and strains at play at each connection. Corrugated cardboard isn't exactly an isotropic material, but the output from this process served as a decent formal inspiration for the overall shape of my construction kit.

I had some scrap 1/4" acrylic left over from another project and decided to see if it would work as a material for my icosahedron. It didn't. I tested a bunch of different tolerances + laser kerf settings, but the acrylic didn't have nearly enough elasticity to accomodate for them.

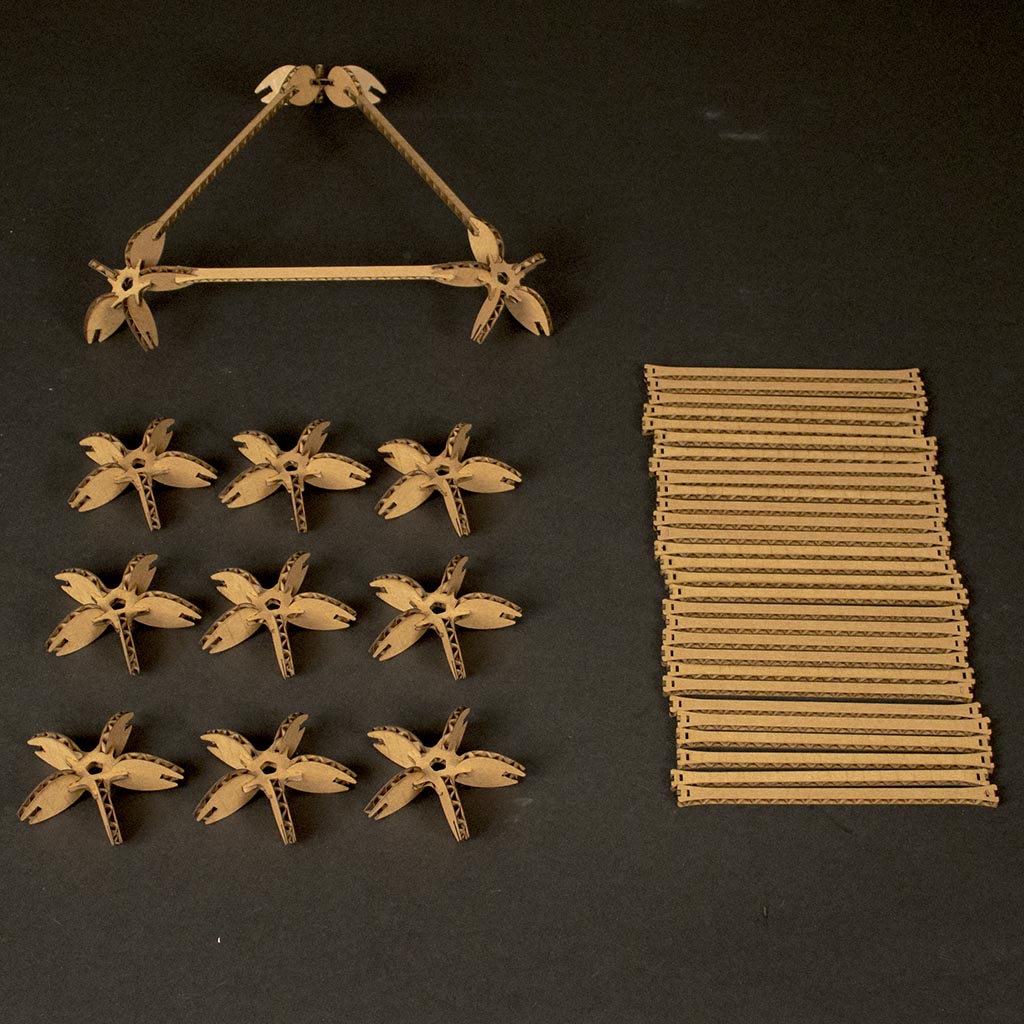

Back to the drawing board. I adjusted my geometry in rhino to correspond with the thickness of the supplied corrugated cardboard. Tested a bunch of different offsets for the kerf - a .018" offset gave the best fit on the 100w Universal Laser at the GSD.

The kit in early stages of assembly. I was sure to cut a few extra of each piece to account for any errors in fabrication or assembly.

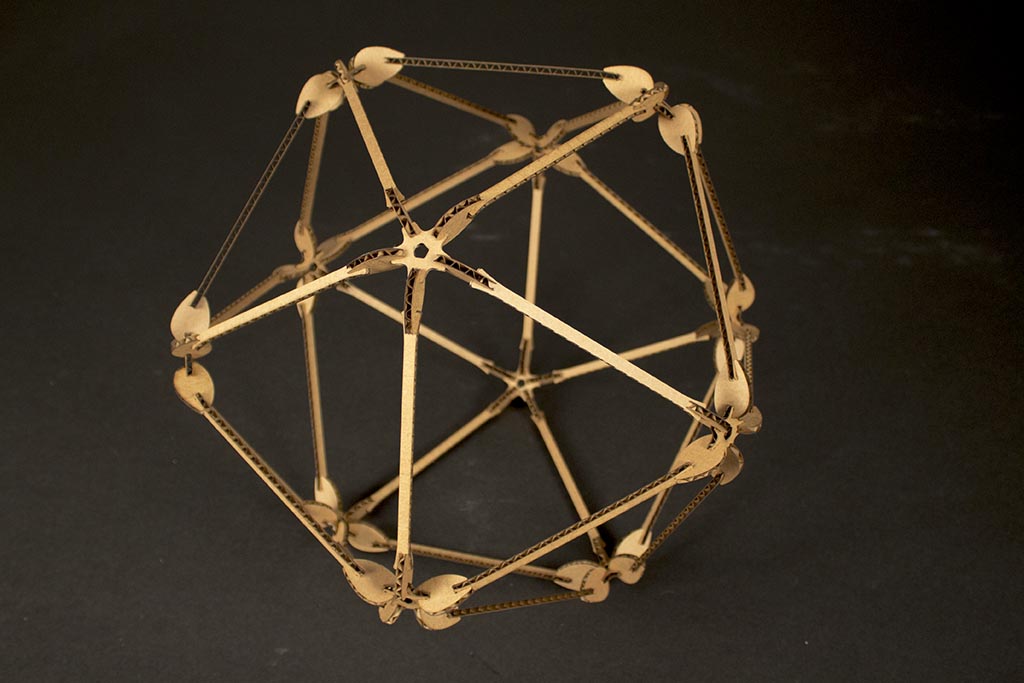

A fully assembled icosahedron. Each edge was designed parametrically, so it will be easy to make a larger or smaller version of this using the same files.