Computer-Controlled Machining

This week the assignment was to make something BIG. I decided to make a coffee table, as the current solution at my apartment is a woefully undersized wooden crate. I had two pieces of 3/4" CDX plywood left over from another project that seemed like a good starting point (and also, free). I have some experience CNC Milling and wanted to use this project as an opportunity to try out a couple different joints and milling techniques.

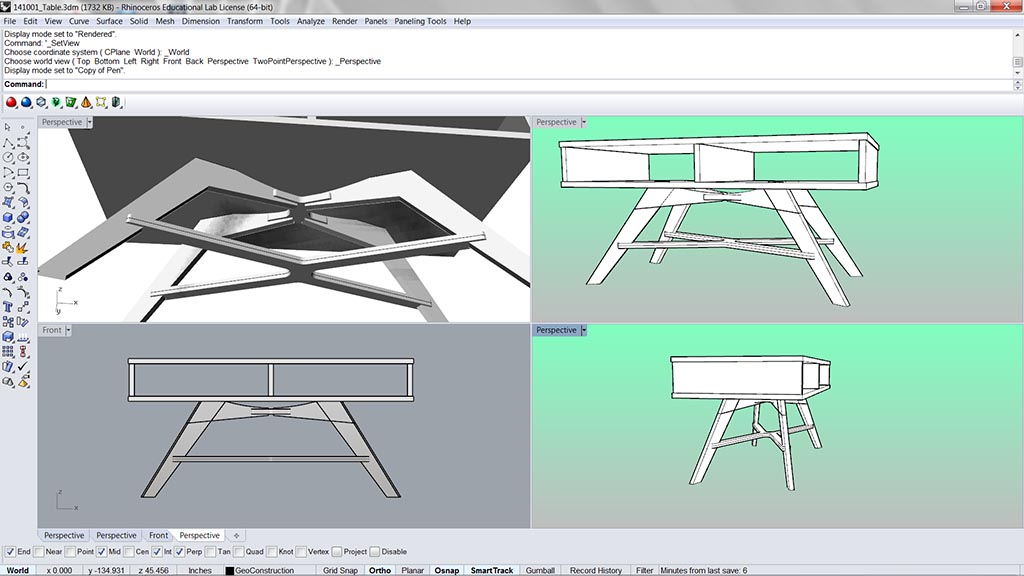

I designed my coffee table in Rhino. I created a couple geometric + dimensional studies, and a few more detailed sketches of joint geometry but never actually went through the process of modeling each piece I wanted to cut as a 3-dimensional solid. The CNC mill only needs information legible from a plan view, so I was able to make some assumptions in my digital model and move on to generating tool paths a little faster.

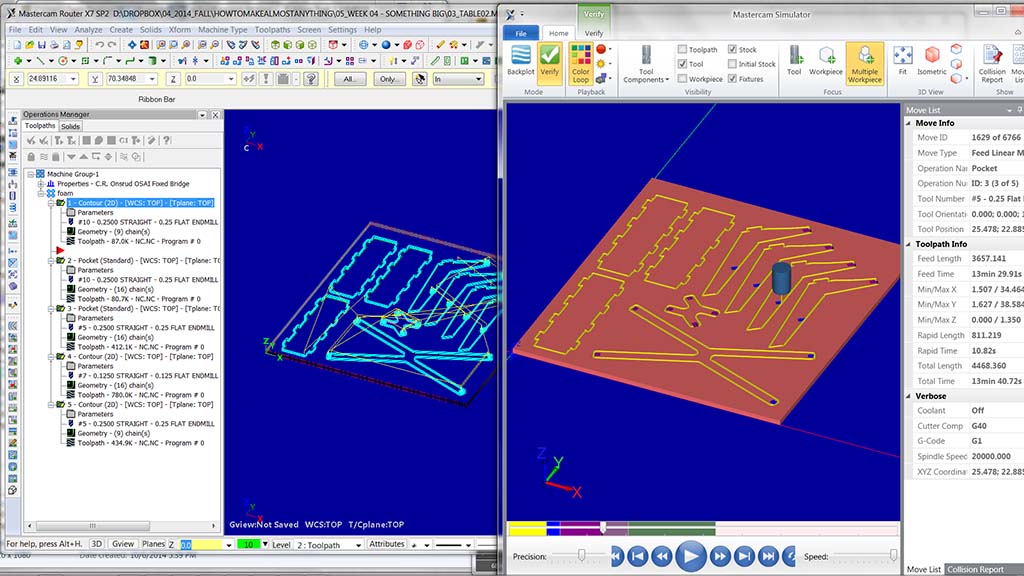

I used Mastercam X7 to generate my toolpaths. In total, this project used 4 .NC files and 12 toolpaths.

In an effort to 1. regularize the dimensions and 2. improve the surface finish of the stock I was working with, I first ran a surfacing pass on each side using a 3/4" upcut endmill with a .3" stepover. I reduced the overall thickness of the CDX from ~3/4" to exactly 5/8". Seen above is one of the passes about 1/3 way through.

I cut 1/8" deep traces of each full-depth contour using a 1/4" downcut bit - this helped to avoid tearout and gave a cleaner finish overall.

The internal voids in CDX plywood played a big part in the success of each part - when I happened to hit one when milling a more detailed section of geometry, there sometimes wasn't enough material to keep the remaining layers from chipping off. You can see some of the detail work I did with with the 1/8" bit to avoid the rounded interior corner problem.

Test-fitting the pieces.

How to Clamp (Almost) Anything.