How to Make (Almost) Anything

Project 4

3D Scanning and Printing

Parameters: 3C Scan, 3D Print

Tool: Sense 3D Scanner, Makerbot

Programs: Rhino, Makerbot Tkinter/Tcl Tk as GUI

Material: Motion Sensor with ATtiny44

Output

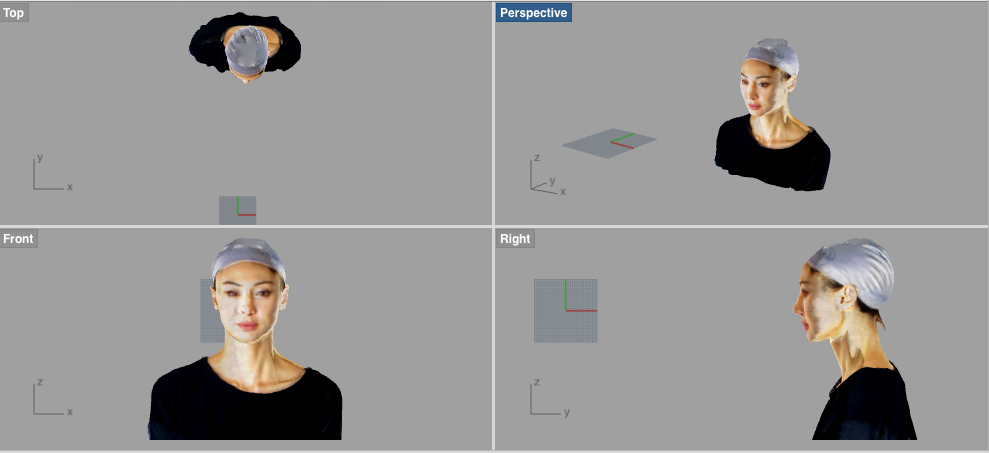

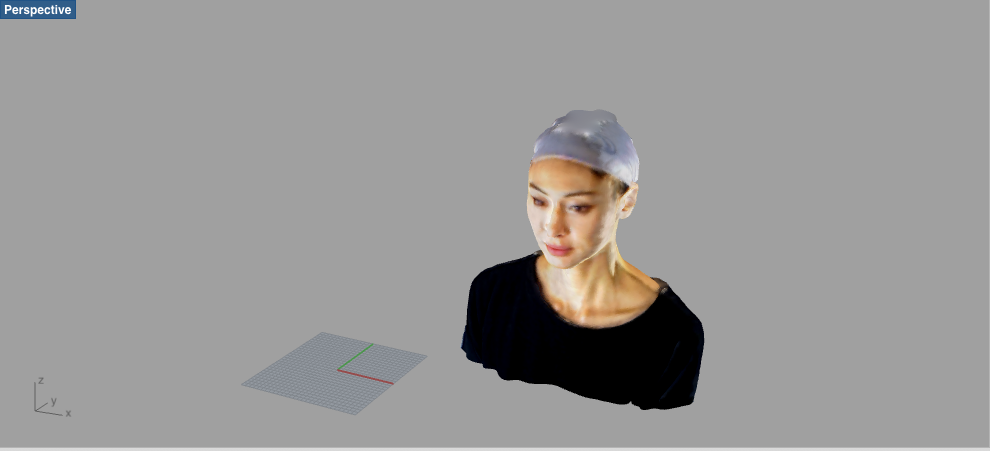

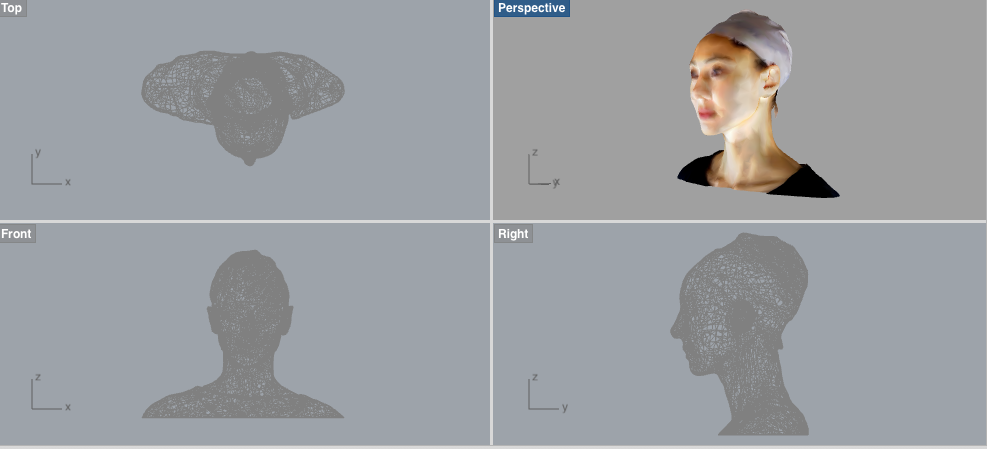

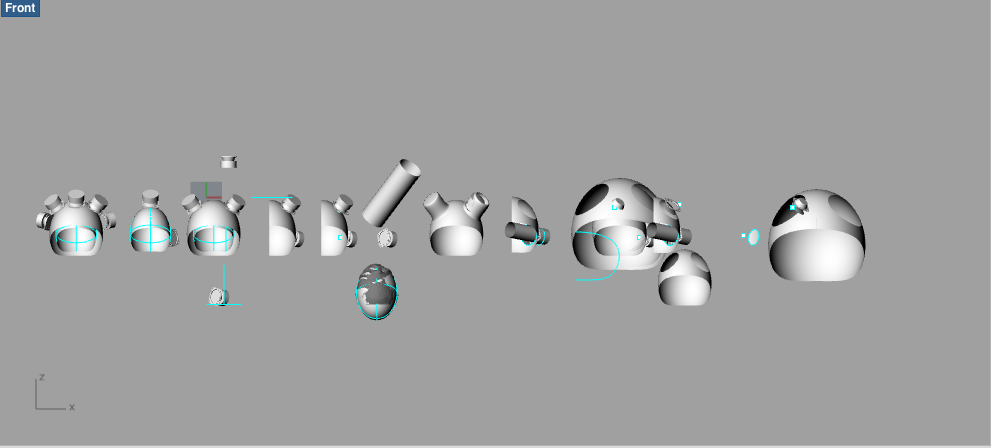

Using Sense 3D Scanner to scan my head to deign a fitting helmet. I imported the 3D scan as .stl in Rhino but as I was wearing a swimming cap I had to correct the ripples by recreating an ellipsoid skull of the right dimensions

The speed of rotation (tip toes or chair) affects the rendering a lot. There is also often a loss of coordinates. Finally a single source of light enables a better understanding of the face volumes.)

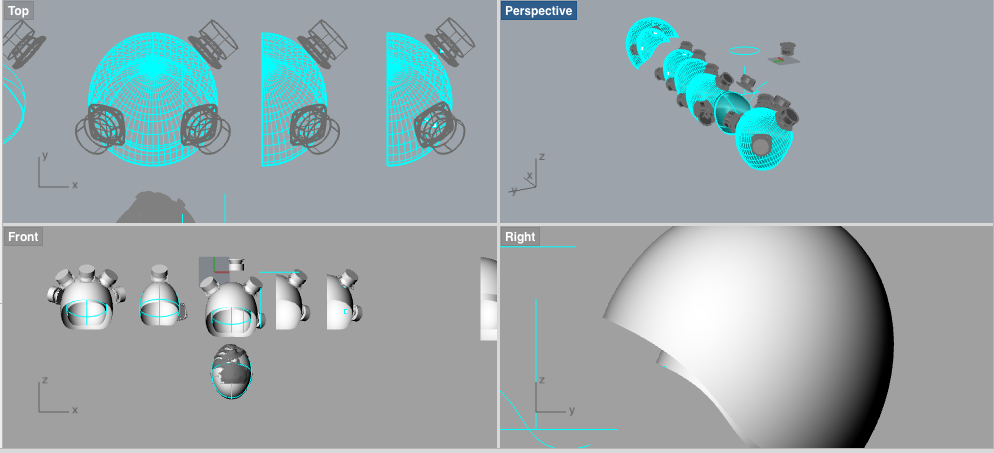

3D Printing: after modeling in Rhino several iterations of a helmet or interstitial space/pod for my directional sound mapping, I realized that if I wanted to machine the mold, the undercuts were extremely limiting. The 3D printing unfortunately never finished because the Maker Bot was out of order, printing "in the void". I have booked time on the Elite Corps machine. I would also like to try to find transparent filemts in order to see the helmet and the embedded speakers inside. The 3D print would give a better sense of the volume.