Cocktail Machine

12. Machine Design

This is the summary from the Stand team (Sam, David, Jake, Calvin, Pierre) for the Architecture shop.

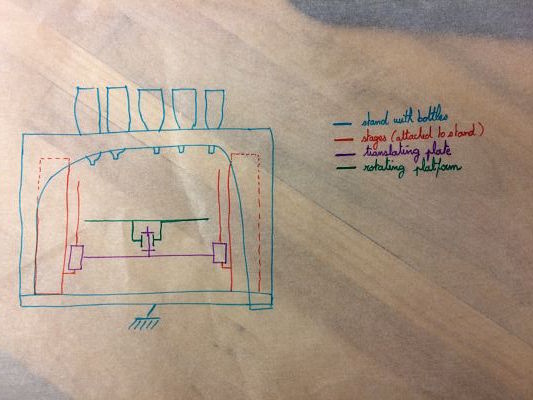

We first started by some drawing and some initial sketching

- 8 bottles on a stand

- 2 cups that are hold diametrically on a rotating platform and that filled simultameously: one cocktail and one "anti cocktail", or the two same cocktails (depending on how we put the bottles on the top)

- One Stepper motor attached to a translating plate that moves the rotating platform

- The translating plate will be attached to the translating parts of the two stages

- The two stages are attached to the stand

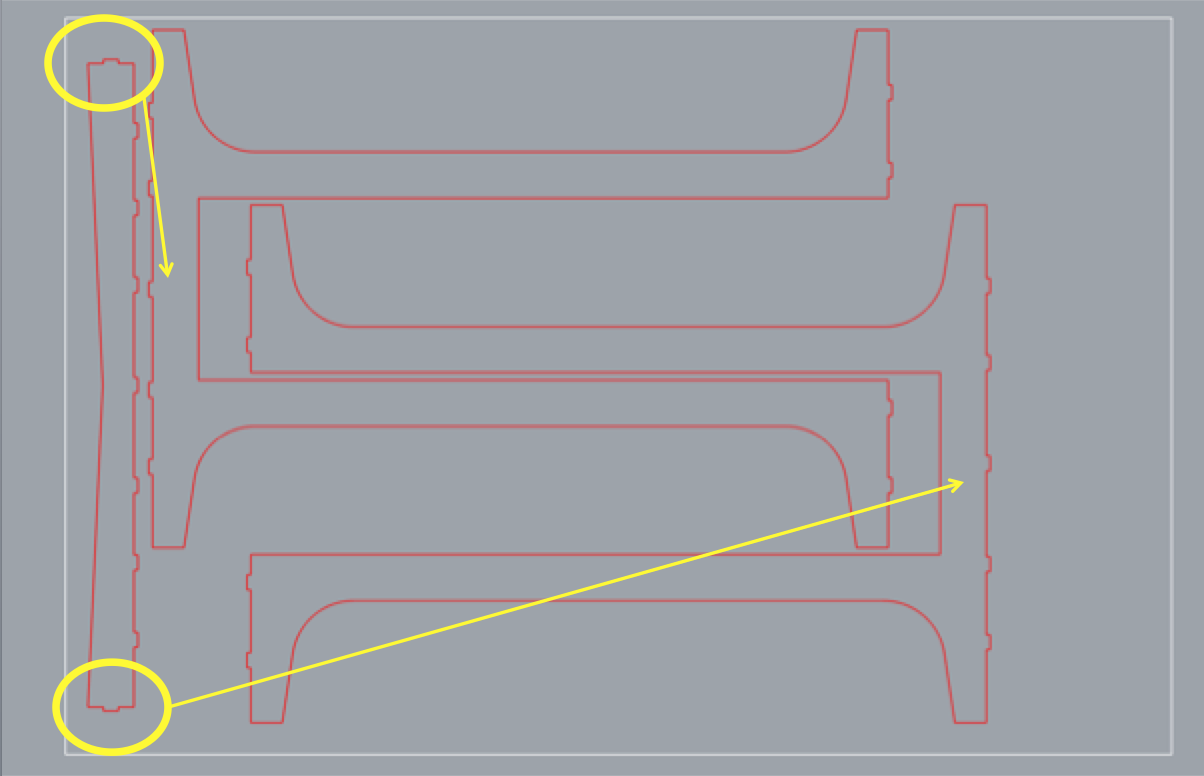

Here is a kinematics diagram showing the different parts

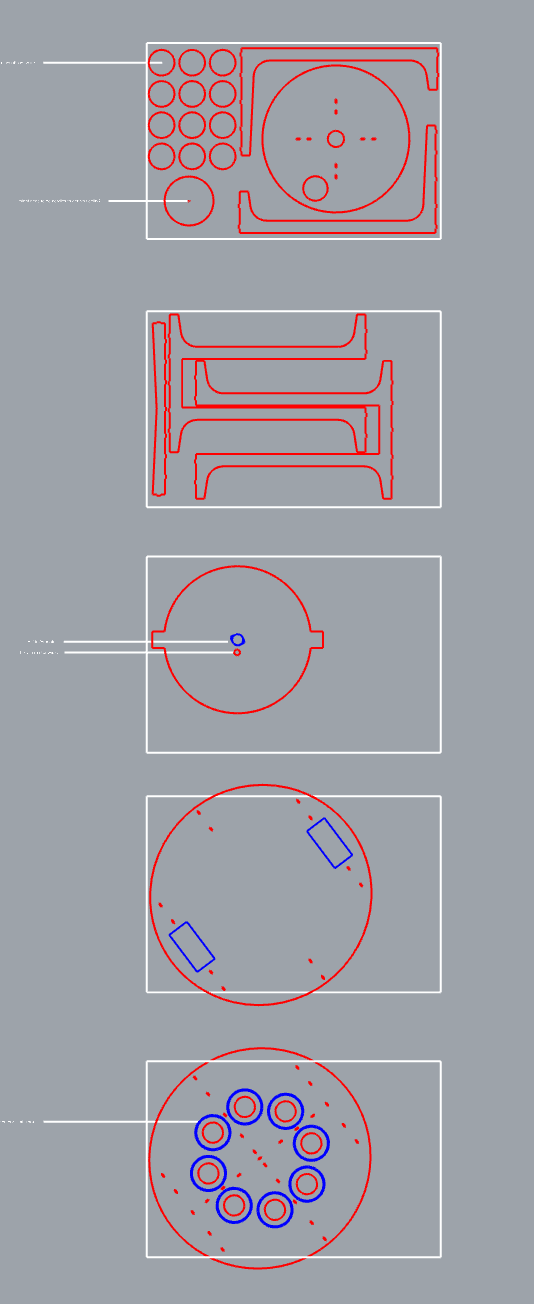

Most of the structure would be made out of plywood to be able to hold the glass or bottles but to be still moveable by the motors. The thickness of plywood:

- 1/4" for the moving parts: translating plate and rotating platform

- 1/2" for the stand

Here are the specs of a Solo cup (x2 in the design) and of the bottle (x8 in the design) we are using

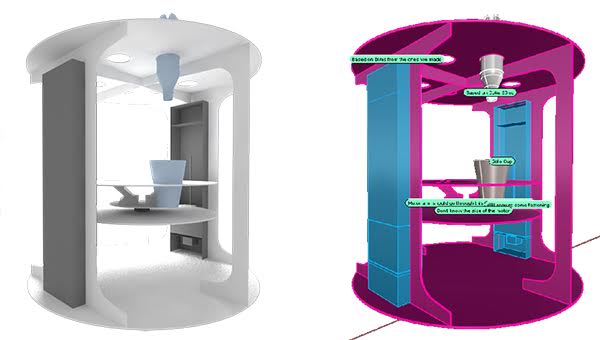

Based on that, we could suggest a first solid Rhino design for the other teams:

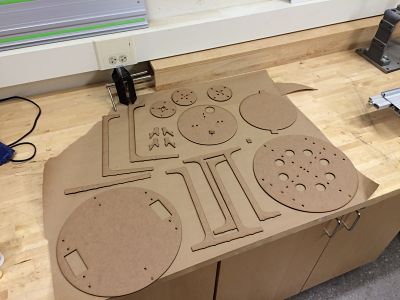

The file was then ready to lay down and print for a first test with masonite to see how it would come up together. I was personally, after the design with Calvin, Sam and David of laser cutting the first model in masonite:

The next step was the assembly:

This first step allowed us to see what were the default. For example, in the design I forgot to put some holes on the top to assemble the higher part:

>

>

We could thus iterate with thicker material such as plywood to have a stronger rack.

>

>

Finally, the rack was strong enough to hold the bottles but we had to change the trasnlating plate material into masonite because it was too heavy for the motors. At the end the project, after some changes and modifications worked very well:

>

>