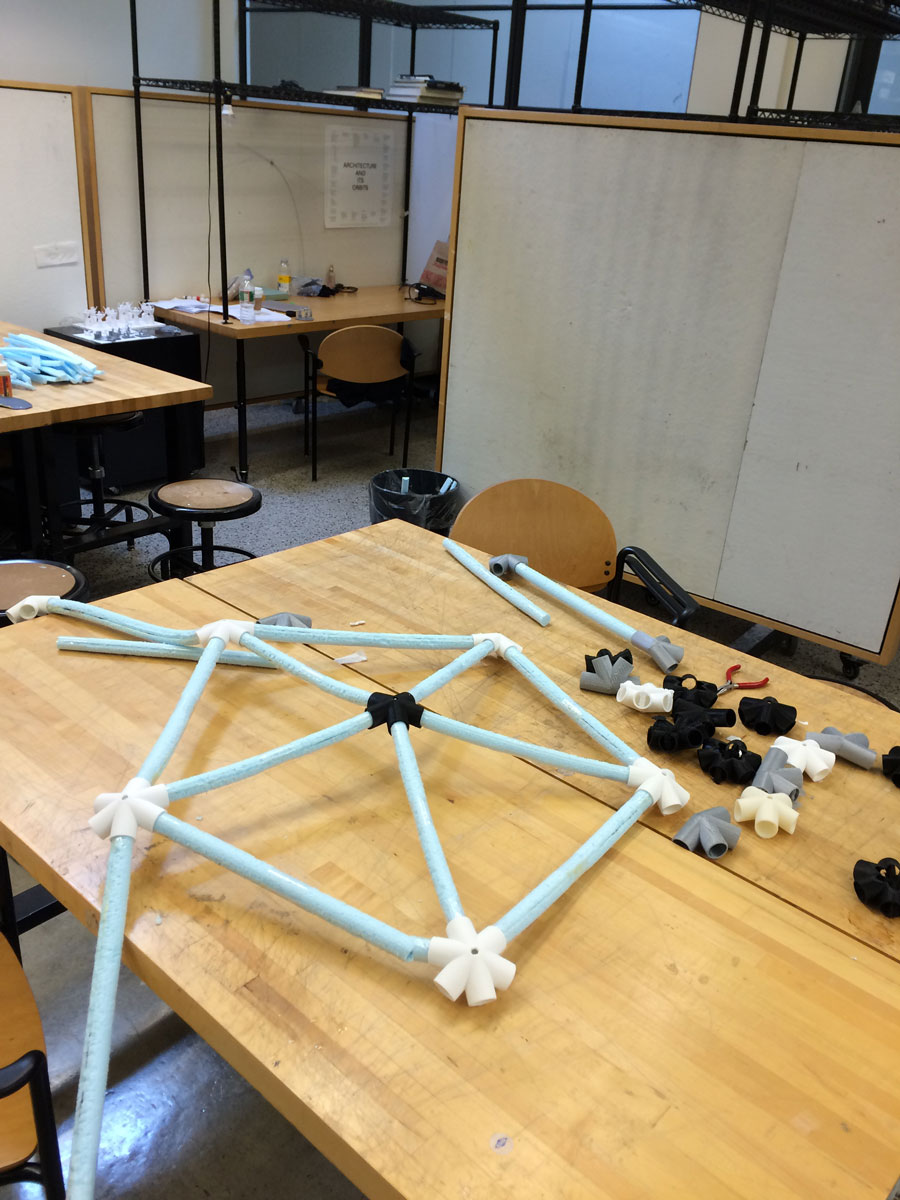

trial_2 (1:1scale)

I had alredy fabricated my struts during the press-fit kit week and nodes during the press-fit kit design week and the 3D printing week. Since milling foam to manufacture struts did not work, and I still had to make something big, I decided to assemble the dome. Even though this assembly didn't involve any multi-axis machining, the dome was surely big!

Even though the press fit technique was working and the struts, even though they were made of cardboard, were strong, I understood that I should definitely have designed a mechanic joint between a node and a strut. Not because it was hard to keep the struts inside a node but because due to the rugged and rough inner surface of the nodes that was created by the removed supports, it was hard to predict how much of a strut's head was able to penetrate. Sometimes they would stuck half way, sometimes they would go all the way. This difference in leghts affected the stability of the dome negatively. It would still stand, but it was very hard for one to comfortably interact with it. So, for the final struts, which I plan on producing with plastics for the sake of making the most of the living hinges,I must define a more stable jointry than just plug in to make sure that the structure is more stable and self-confident for interaction!

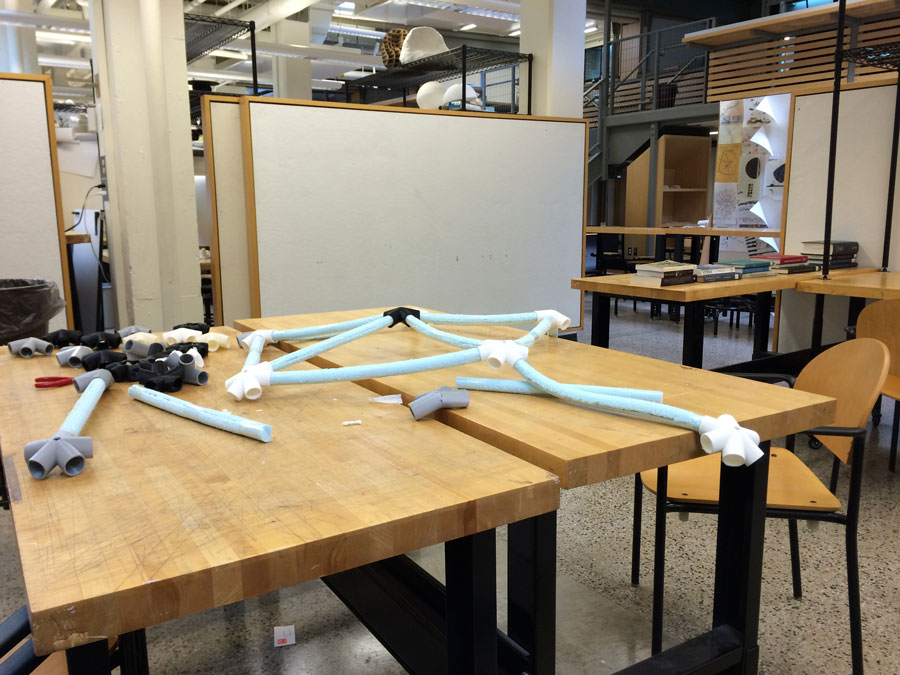

trial_1 (1:2 scale)

I have decided to build 1/2 scale model of my final project. I had already printed the nods during the 3D printing week, so I decided mainly concentrating on the struts. The problem was, we were given only 2 options as materials to be used: wood or foam. Now, since I needed tube-like forms, that meant I had to do 3 axis machining in order to shape the surfaces. Considering I had more than 70 rods, that would take forever with the wood. Also, it was important for me to keep the structure LIGHTWEIGHT and make sure that the PLA nods would not crack. Therefore, I went with the second option: foam. However, considering how strong foam is (it ended up parforming even weaker than I had anticipated), I decided to build a half scale model, instead of a full scale one as I had intended.

Used the onsrud to mill the foam boards. Even if I was using multi axis machining, because of the undercuts of a typical cylinder, it would not be possible to mill it out as an entire cylinder. Thus, I have split my cylinders into twho halves, to be glued together once they are milled.

Semi cylindirical profiles: As if foam by itself was not weak enough and the struts were not thin enough, me being had to split them into two ABSOLUTELY did not help the strenght of the struts as can be seen below:

Since my geodesic dome has frequency level of 2, I had only 2 different lenghts for the struts. After gluing two halves into one cylinder, I have connected the foam struts with 3D printed nods.

After the first pentagon, it was obvious that the structure would not going to hold up... I started searching for a material that was nor wood neither foam to build the struts with. Since I have experimented with the multi-axis milling machine ones in this unfortunate failure, I though I could use a different fabrication method for making something big!