For this week, we were responsible to making the FabIsp.

The FabIsp will allow us to program other devices. For this lab,

the main two components we had to do was too mil the pcb and then

attach the desired components on them.

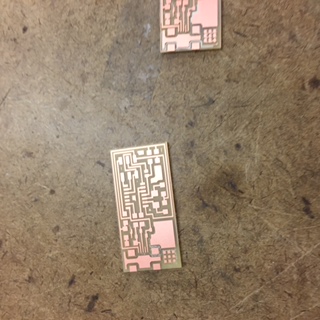

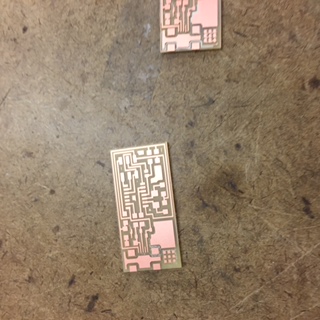

The pictures of milling of the milling are presented on the left.

The main problem I had with the milling was that I did not tape

the device hard enough. I redid the milling and it came out better.

The appropriate picture of the milled board is on the left. The two key things

are that you have to change the depth to 0.12 and you do not have to change the z height.

of the devices.

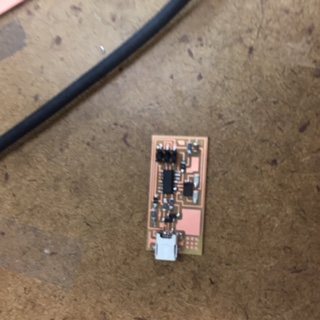

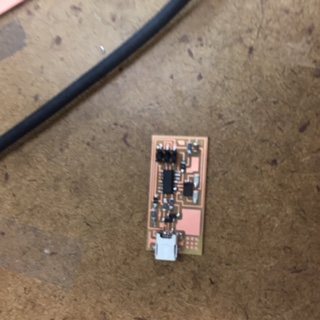

The soldering was very difficult and I was not able to get it to fully work.

I am pretty close, I just need to be able to desolder with the wick

appropriately the usb cable.

Overall, the strategy of taping of all the required components to the paper

seems pretty useful. I eventually redid the fab isp. I am not sure what exactly what was the problem but it now works.