Computer Controlled Machining

Aperture Table or Expandable Pizza Pan

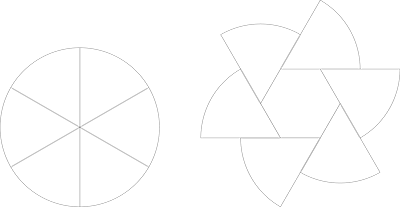

Following the traditions I've decided to produce a table. I was interested in variable openings like the diaphragm of a camera so I went on to translate this idea into the furniture.

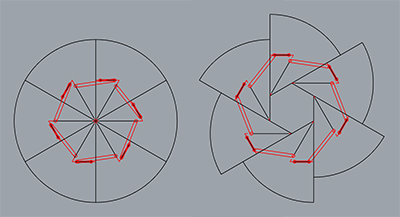

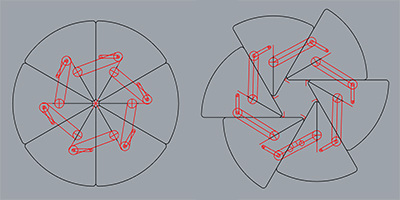

I made some small scale paper models and sketches; and figured out that it may be better to continue sketching in Rhino. I spend a lot of time finding appropriate positions and directions for pockets and cuts for the connecting rods. For this reason, I had to skip Sunday and Monday sessions at N51. I've decided to manufacture my first full-scale prototype despite feeling that two cuts on each pie would produce better constraints on the path of the pies during the expansion. On Monday, I arrived at N51 at noon and resolved some minor issues about the mechanism with Chris. The waiting line was long and I could only started deciding on the tool-path in MasterCam at 5 pm.

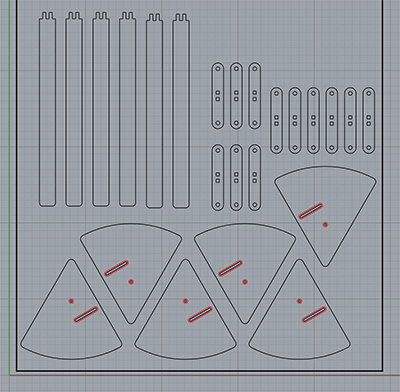

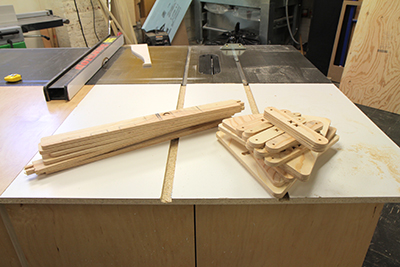

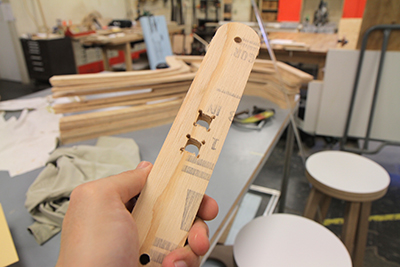

With the help of Justin, we chose 3 onsrud tools and 4 different operations. We used Contour for boundaries by leaving an onion skin, Pockets for pockets and also for interior holes, Drill for drilling the interior corners of the holes and teeth to Re-machine it further for producing square holes, preventing automatic fillets consecutively. We used Contour again to get rid of onion skin in the end. The MasterCam animation and the GCode proven to be ok and I was ready to cut my 0.43 in of plywood.

The parts were ok. The only problem was as I've decided to keep the thickness of connecting rods in 0.43 inches(single layer of plywood)instead of pasting two together to achieve thickness of 0.84 in, I had to cut the length of the teeth in half. But as I was more interested in the success of the mechanism, I left the former for another time.

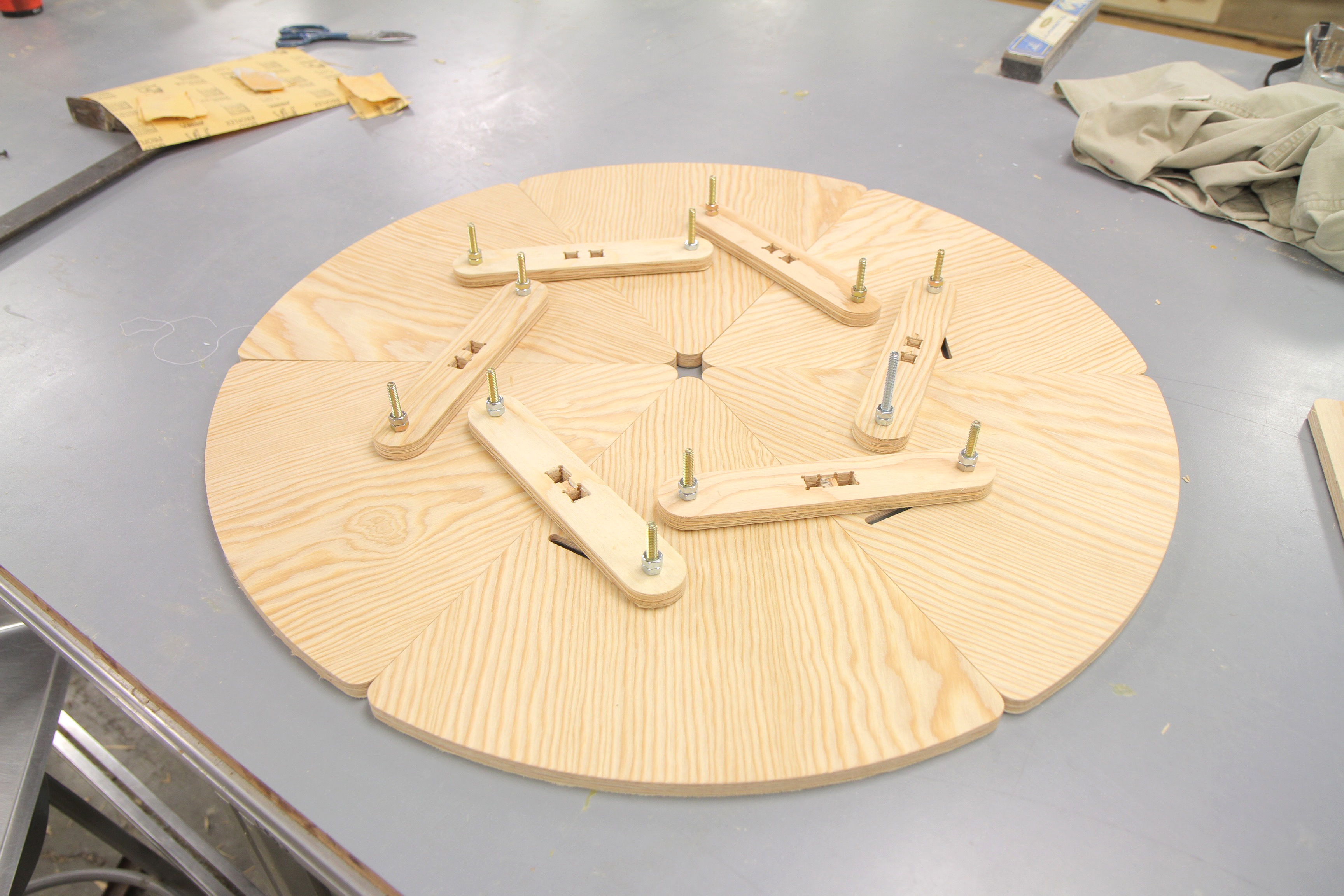

Then, I started assembling the parts. Notes on the mechanism: Initially I was thinking to produce bolts, nuts and washers from the plywood as they were seeming ok in scale for manufacturing. However, through the resolutions with Chris, I have decided to use quarter inch steel threaded rods with 0.35-in nuts and 0.5-in washers. So starting from the top,you put a washer

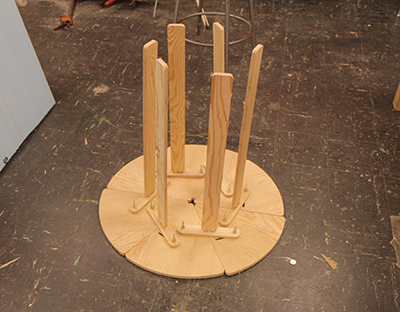

I have assembled it. But I had a problem of course. I need to put additional pieces to constrain some degrees of freedom

It looks fancy, but I need to figure out the additional pieces

I came home, studied the mechanism with additional nails and rubber bands. I hope I will be able to improve it.