Molding and Casting

A radiator for bed

Decided to make use of the conductive(if any) and aesthetic qualities of the Hydrostone. I thought that it might be cool if I can use that to heat my bed before I sleep. Two design constraints were necessary: (1)I had to make my mold in a way to yield my final design hollow and (2)I need a better conductor residing within the object in order to store the heat better.

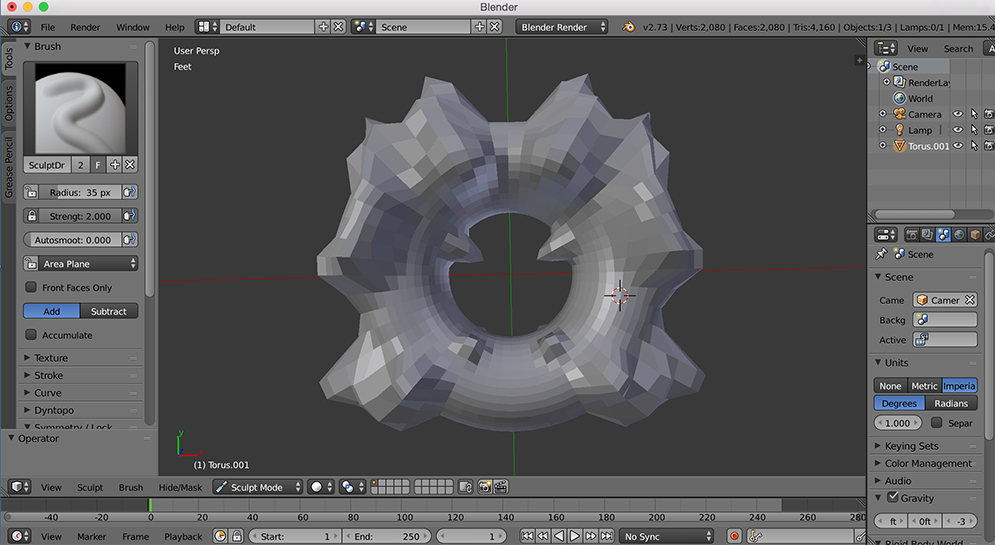

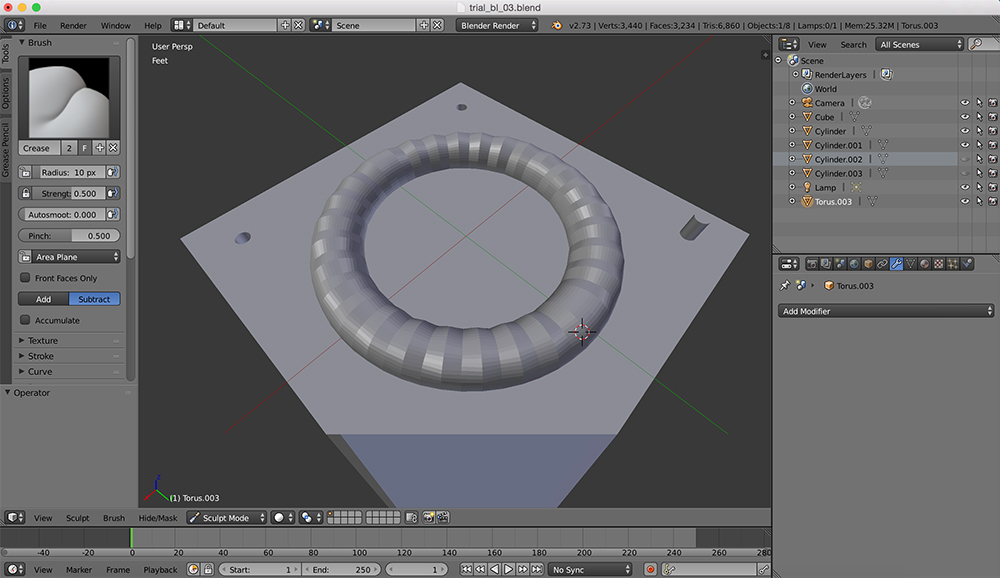

I started to design the radiator in Blender, as the software is good for free-form modeling and sculpting. Moreover, in Sculpting mode, there are many cool brush modes that help you translate your modifications in one dimension(X) reflected to other dimensions(Y or Z or both). This feature helps the designer to produce symmetrical designs which may be relevant for some aesthetic considerations.

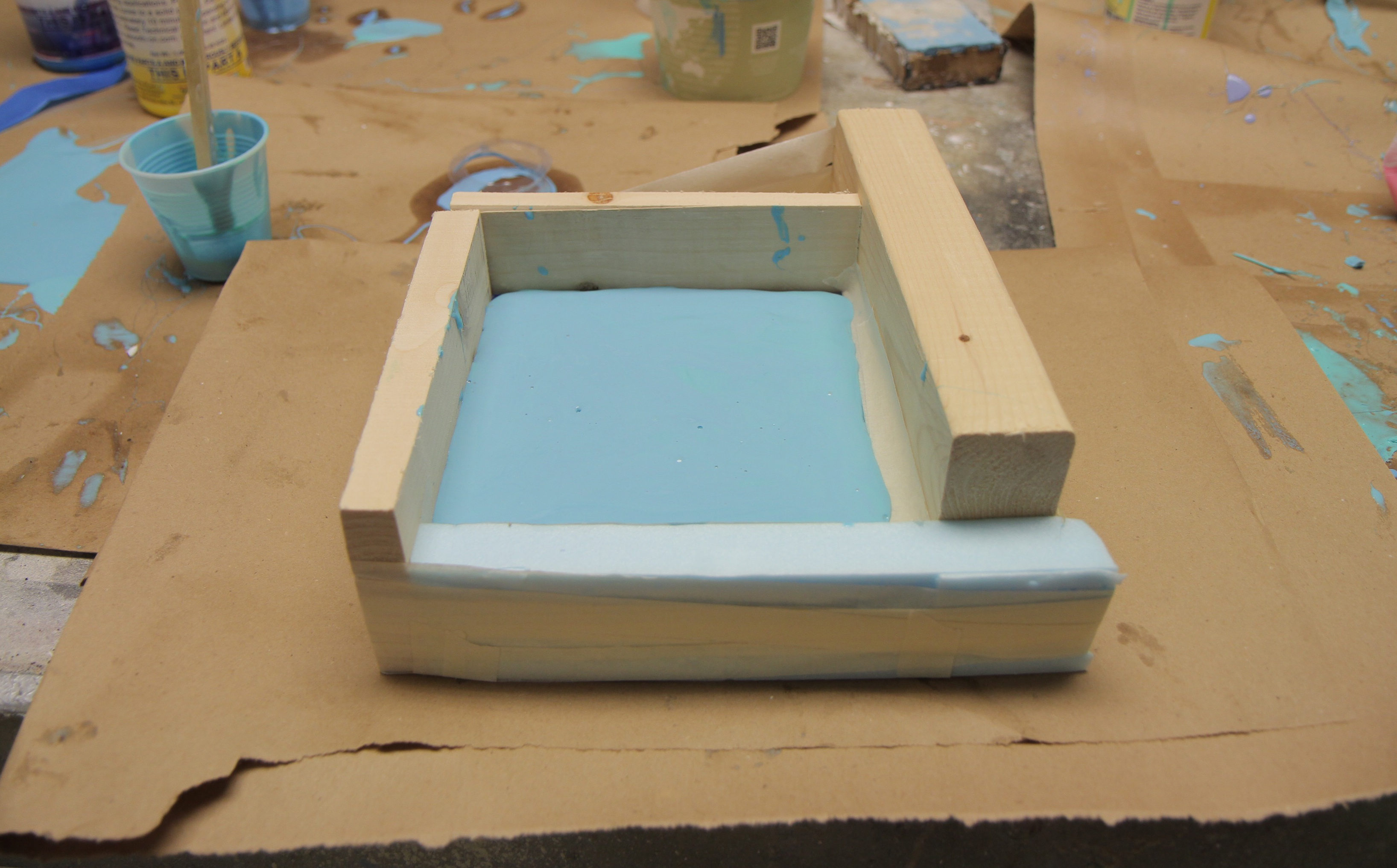

To make a wavy surface, I've used the SculptDraw mode. I kept the positive form, buried half of it within a larger half-cube, my first mold-frame. With some boolean operations, I positioned two holes and two teeth on the mold-frame which will help my two oomoo molds fixed together. I've also inserted two small holes on the positive in order to clamp the inner tube during the casting process. I was able to work on a 6in x 6in x 1.2in large cube as I found another machinable wax from one of my friends.

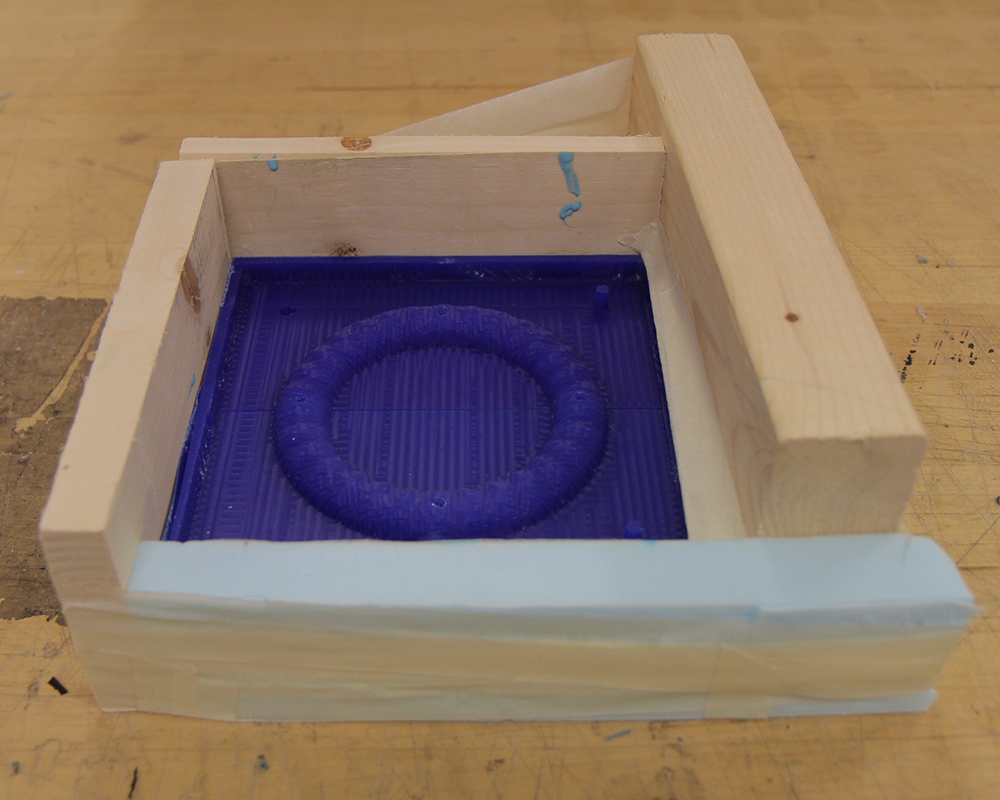

After taping two wax together, I milled them on the modela. I haven't changed the end-mill after the rough-cut so after the finish-cut, I get a weird surface. The planned holes on the object were not deep enough probably due to the size of the holes. I made them a little deeper with a screwdriver.

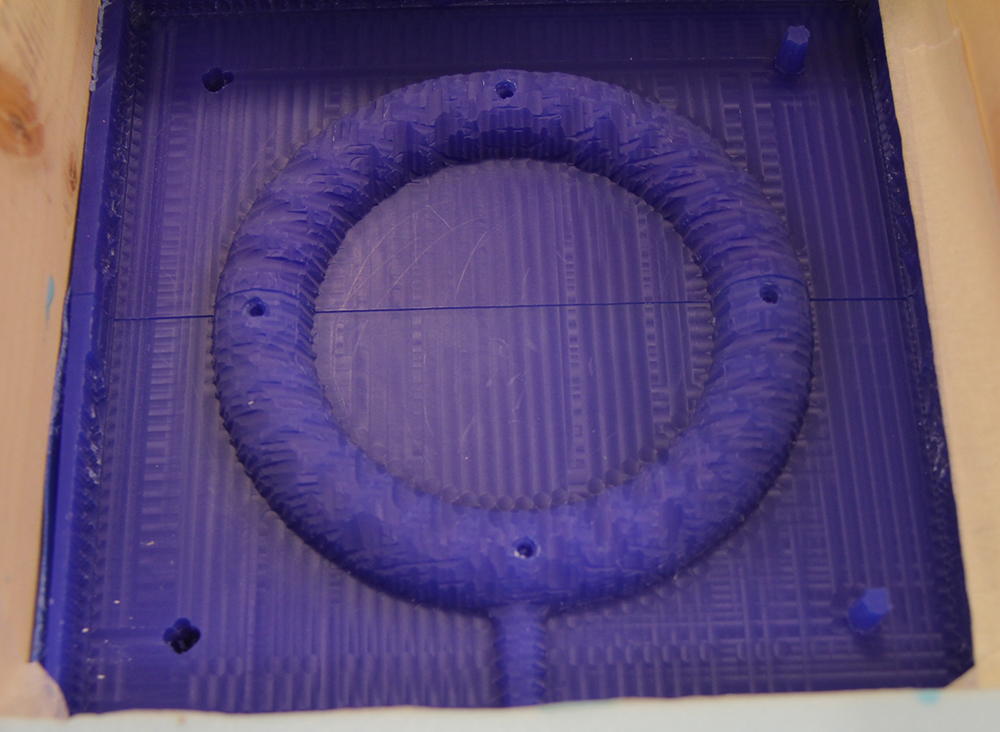

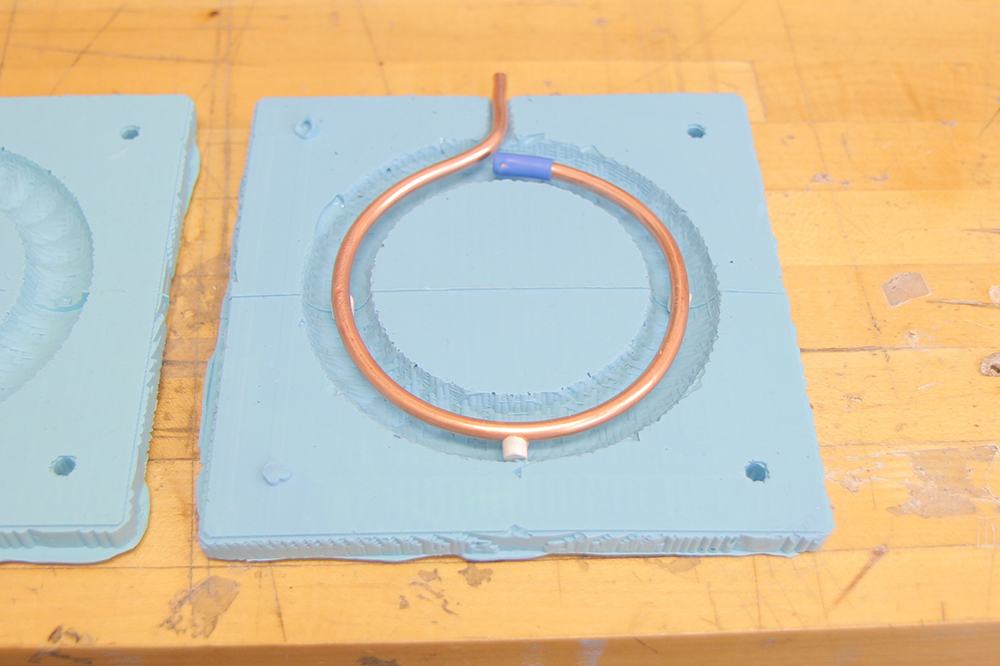

I cast the oomoo on the wax, waited for one and a half hour and cast the other part. I was semi-careful while mixing the silicone, so I get some small number of unwanted bubbles throughout the silicone mold.

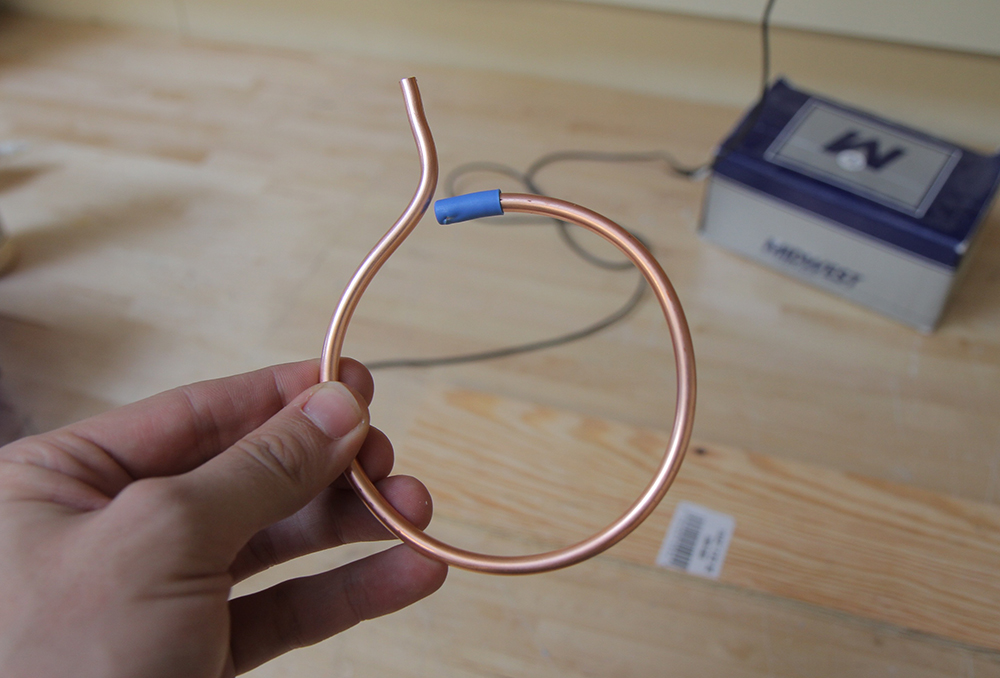

I bought a copper tube with an outer diameter of quarter inch. Manually bend it into an appropriate form and closed one side with a plastic cap. At this point, I have figured out that I had to include another hole for releasing the end of the copper tube, in order to allow for the air to go out when some hot material is poured from the other end. Furthermore, this move would help me to produce a current through the copper tube, achieving heat through electricity. As this was my first prototype, I've decided to move on with my previous mold to demonstrate a proof-of-concept.

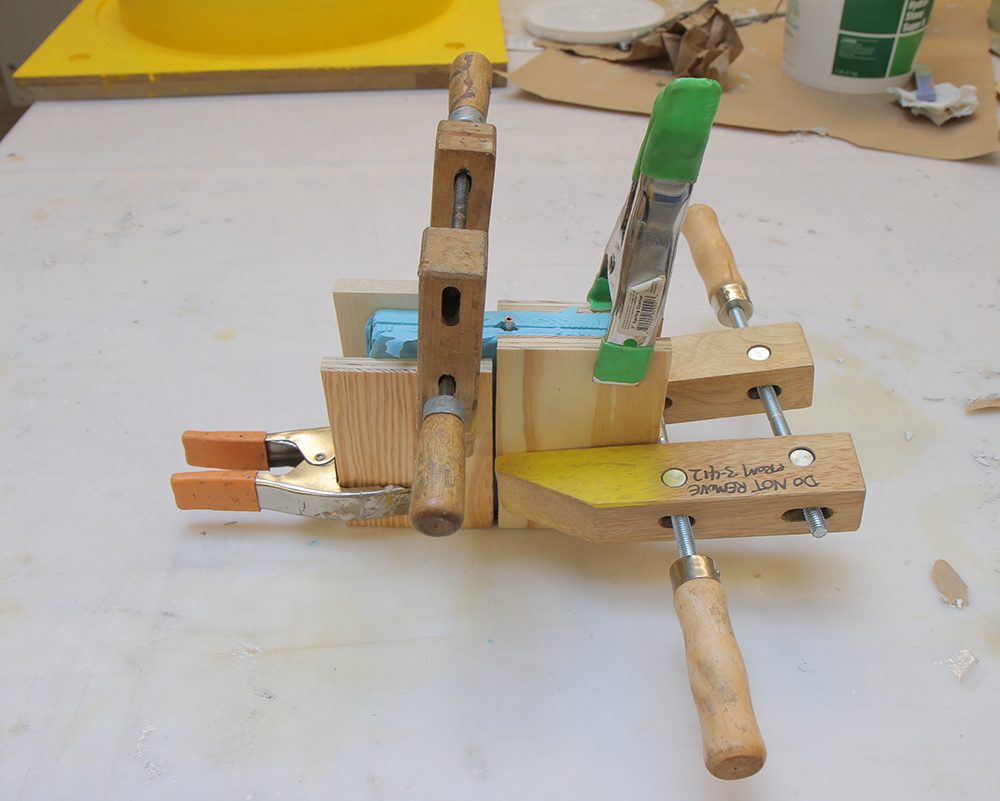

Then, I have clamped my mold, putting some plywood layers in between. I poured Hydro-stone from the sides of the nozzle. That small bubbles resulted in small leaks of material therefore, I need to pour some more material after 10 minutes.

And here you go! Would be nice if I can manage to produce the second prototype.