This week, our job was to mold and cast something following the process of making the positive mold; then casting the negative silicone mold; and finally casting the part. Given that this week I had a design challenge from one of the companies I am interviewing for, I thought I would combine both activities. The challenge? Design a battery door mechanism that is robust, easy to manufacture, and a delight to use.

My ideation process started with a lateral exploration of a many different locking mechanisms. I tried to think of simple ways I could design a "push-to-open" mechanism - one where the same action is needed to close and open the door.

Spring loaded push slider.

Bi-stable plastic snap fit.

Asymmetric cam mechanism.

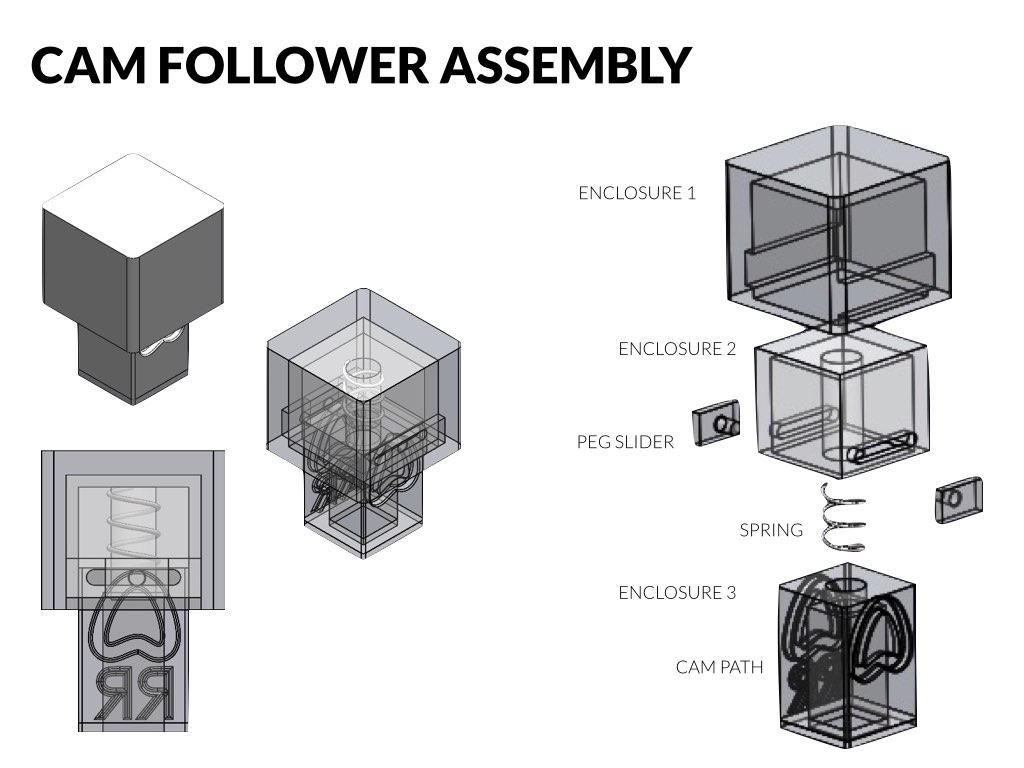

I chose the cam follower as I thought it was the optimal mechanism with met the engineering specs and product attributes desired. So going into Solidworks, I modeled the mechanism and exploded the view.

An animation of the cam-follower using the Path Mate Motor in the solidworks simulation tool, under Motion Analysis.

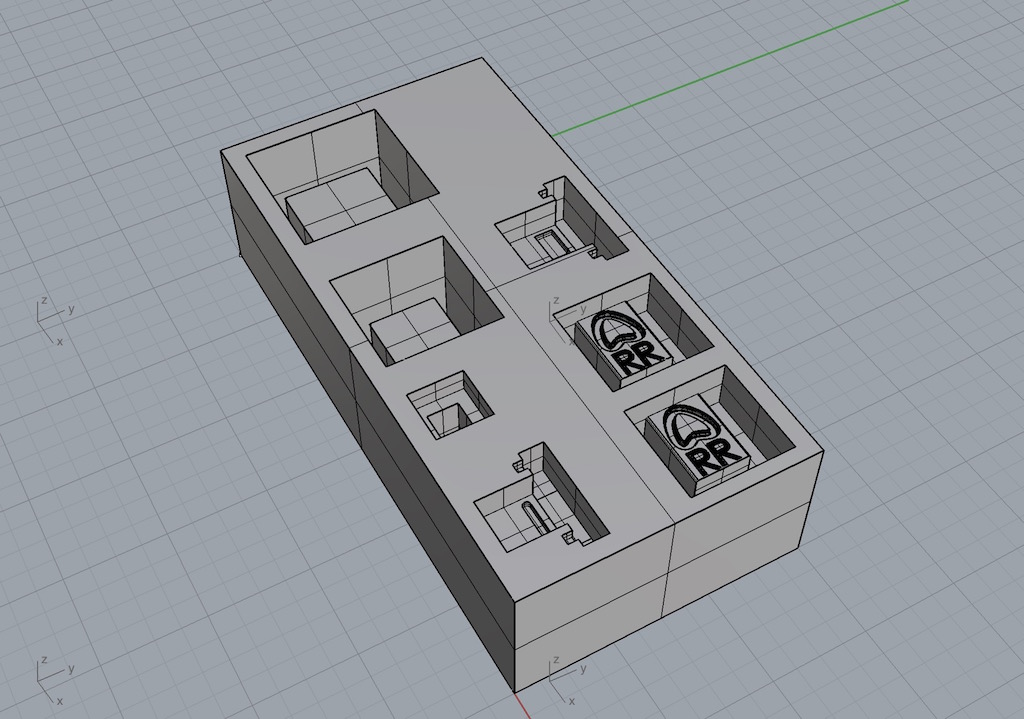

I then went into Rhino to model the positive mold of the different elements of the assembly. Here, I found it quite difficult to imagine the process from positive-negative-positive; rather, I continued to think of just the negative silicon mold. In Rhino I used the BooleanDifference and OffsetSrf tools to generate the molds from the STLs in Solidworks.

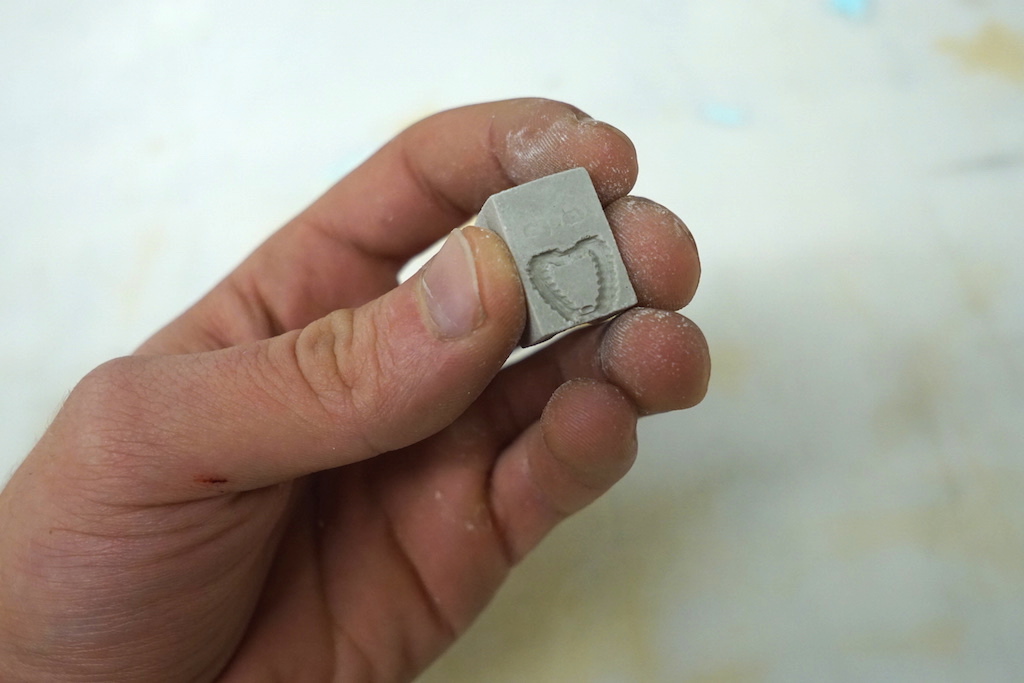

One of the final parts! While my initials were to small for the 1/32 end mill, the part came out well! For the parts with the holes inside the thin shell, it was very difficult to demold without breaking the hydrostone. In the future, I would increase the number of molds and the draft angles so that I can easily separate out the inner and outer molds without breaking the sh

I learned a lot this week. I specifically learned about three main things: draft angles, tolerances, and undercuts. While we were using silicone molds, it will be necessary to design a draft angle for future molding endeavors so as to easily demold the parts. For undercuts, I realized that every time there is a point of inflection in my mold, I need to add divide into another mold so that we the mill can mill it out (it cant mill sideways and down). And finally, I also learned that with small features, tolerances become even more important since the parts get closer to the order of magnitude of the tolerances themselves, making jamming likely.