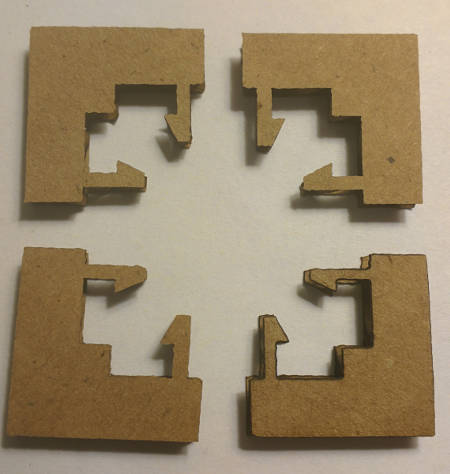

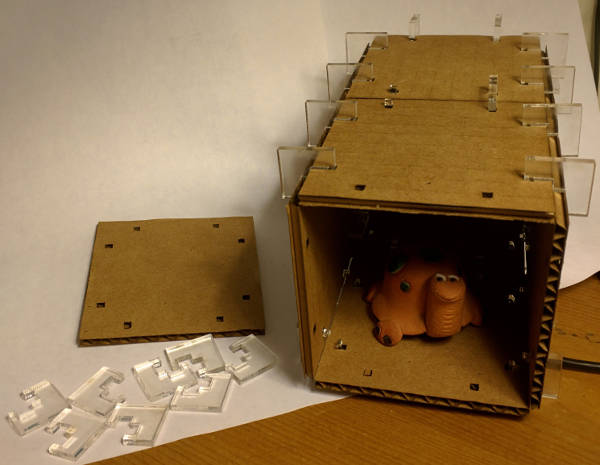

Press-fit Construction Kit

or how I learned to stop worrying and love the cardboard

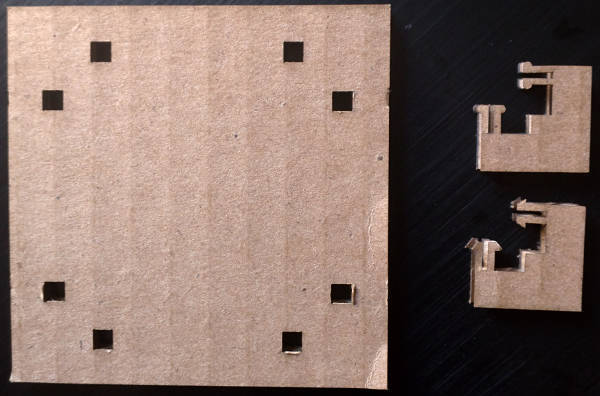

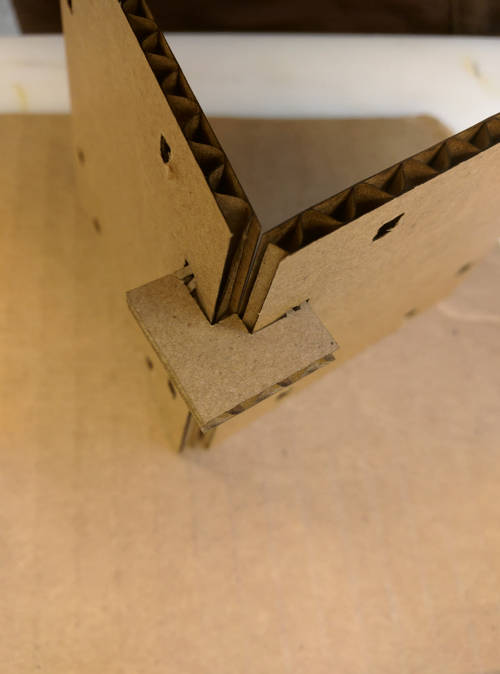

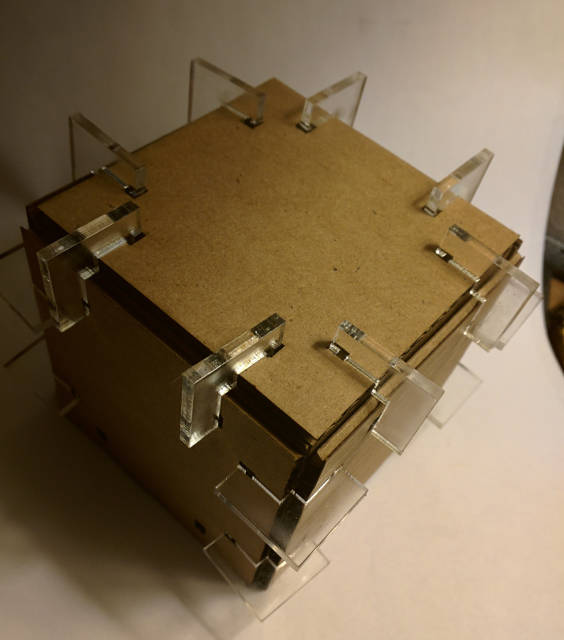

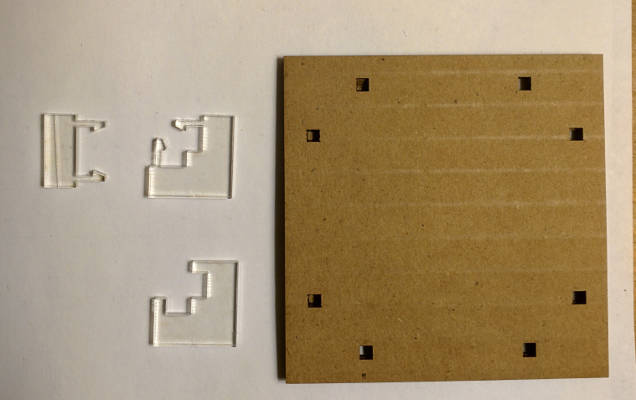

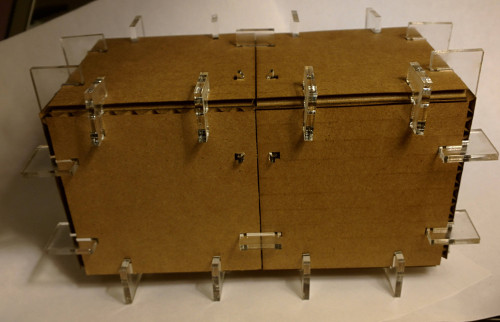

To explore laser cutting I wanted to play with the idea of puzzle boxes. While puzzle boxes are really cool, they are typically constructed once and then always have the same solution. I wanted to explore the notion of being able to change the form and function of a puzzle box - in essence making a puzzle box kit.

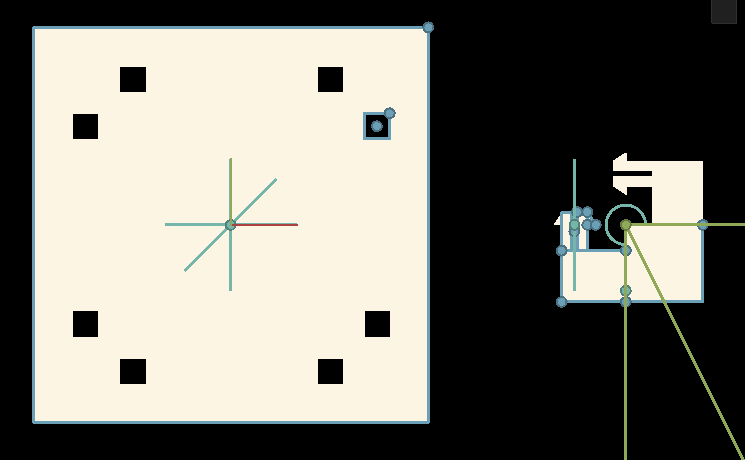

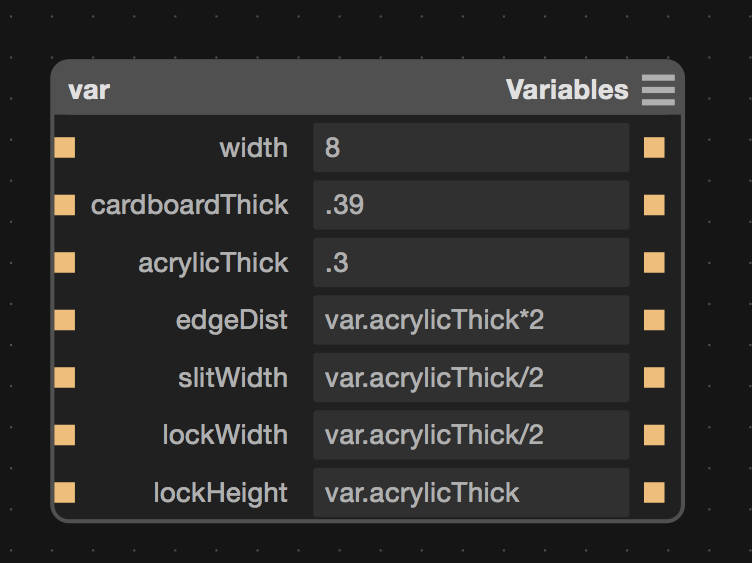

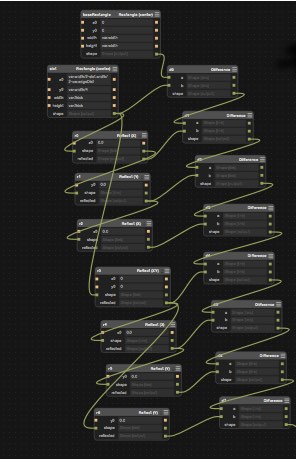

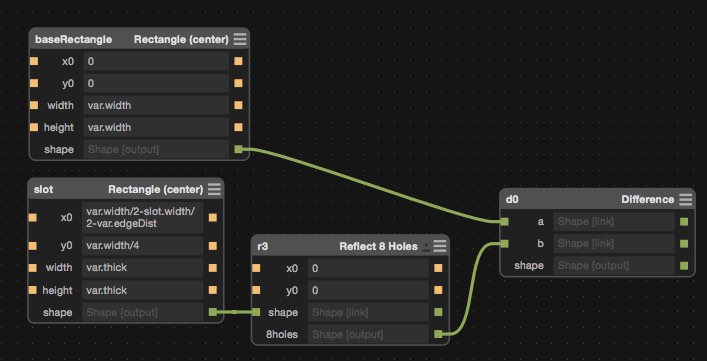

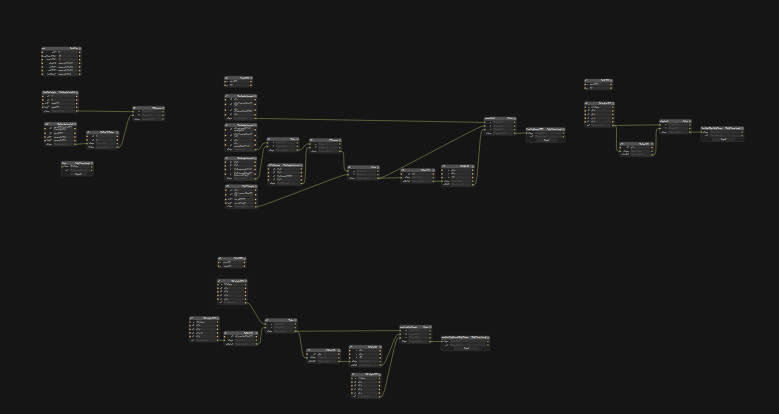

I decided to use Antimony this week as I wanted my design to be very parametric. This would end up being particularly helpful as I was able to change parameters as I made design decisions throughout the process.

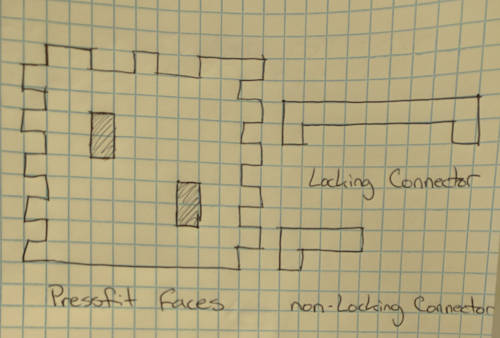

Little did I know what I was getting myself into. I was initially inspired by the example joints shown in class and also this article on CNC panel joinery.