Week 12

Composites

This week, I decided to make a chair seat + back, inspired by the Eames Plastic Chair. Instead of working epoxy, I worked with the Kuka robot arm and thermoplastics.

I was super interested in Composites this week, and I thought that it would be really cool to do a chair seat and back with this-- I stuck with the black polyprop. + milled the seat with the shopbot.

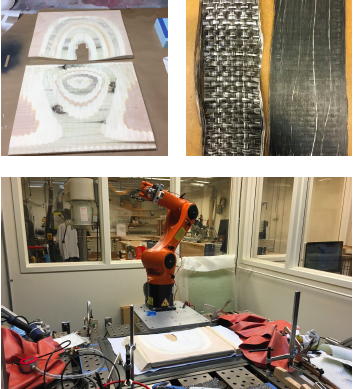

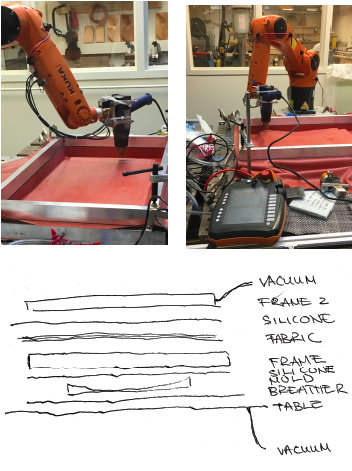

Here's some setup pics.

This process took from 1PM to 7AM the next morning (I had two parts to make). Nico and I decided that we wanted to do more tests-- maybe even shorten the time at around 2 in the morning. The heat gun was set at 450 F, moving at .25 mm/second. Over a 12x22 surface, this came down to ~7 hours.

We did a quick test -- the above was done on the vacuum/multitherm. We started with 210 C, heated very briefly, and then put it into the top with a makeshift mold. This came out really quickly, but was more brittle and did not flow well.

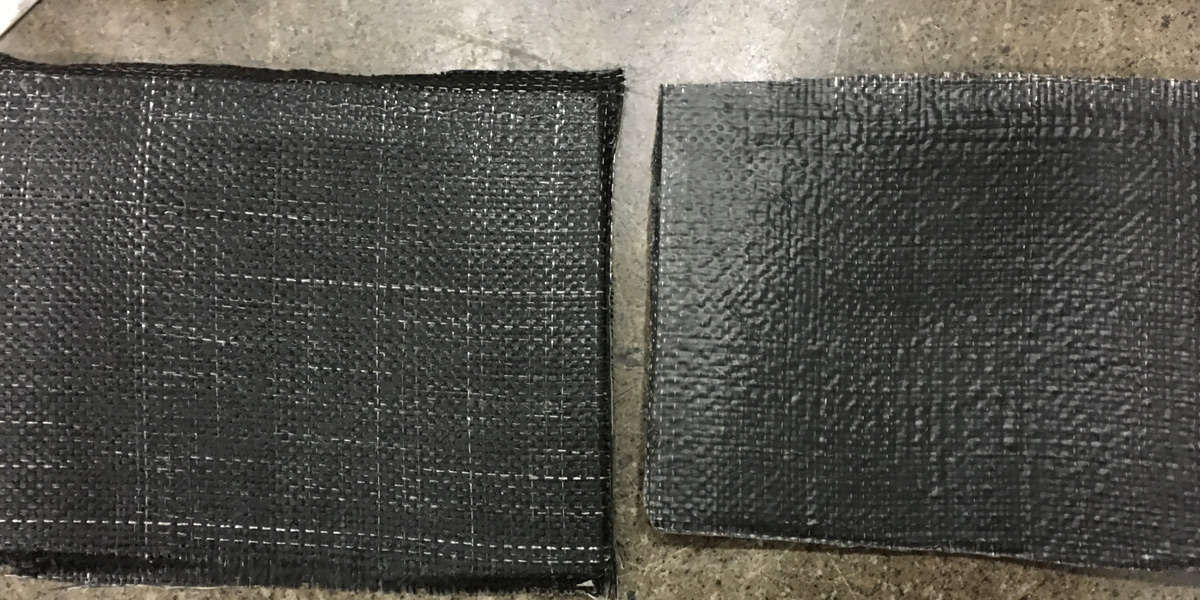

Left (180 C, 30 mins) was done on multitherm, right was done with Kuka arm. There is an obvious difference, but the left was done in 40 minutes, whereas the right took 6-7 hours. The one on the right is much smoother and not as rigid or brittel as the one on the left. However, I think the shortened time is very much worth it.

We did more tests, including using waxed aluminum on one side, heating slower and at lower temperatures. Will update on chair as soon as everything is assembled.