HTMAA - Week 4: 3D Printing and Scanning

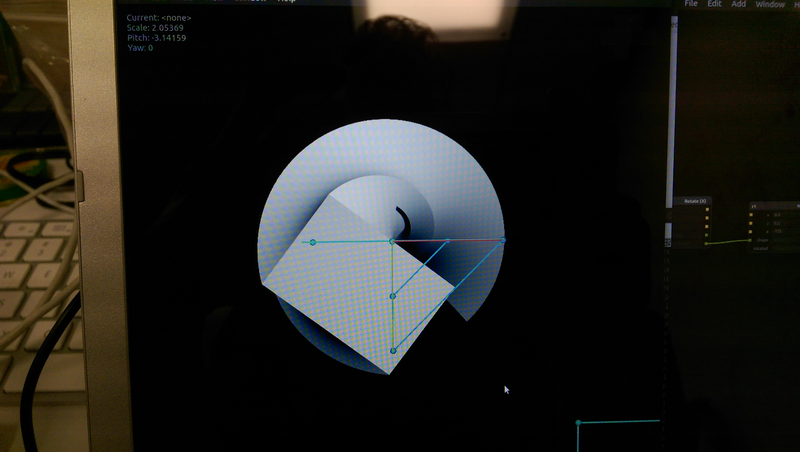

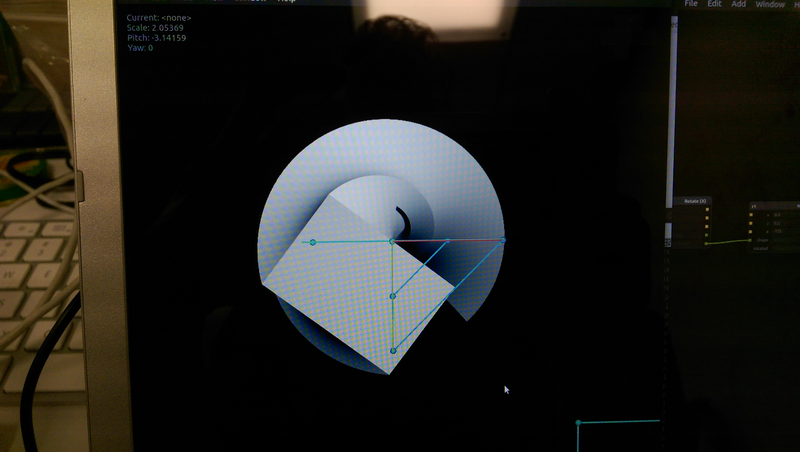

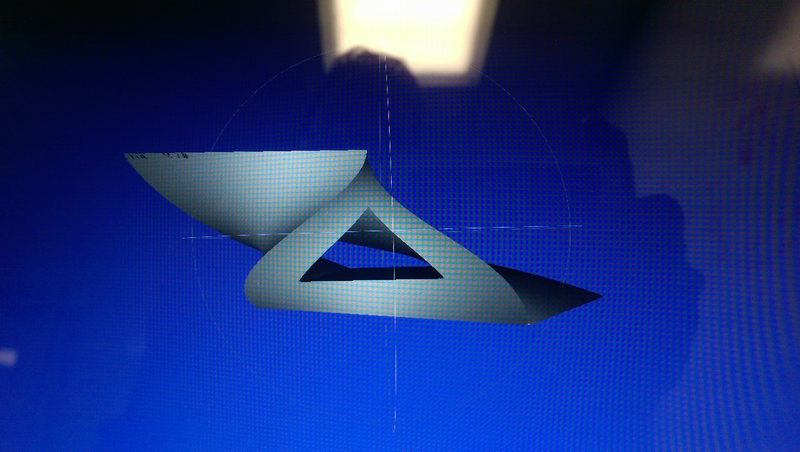

For 3D Printing week, I chose Antimony because of its ability to twirl objects and create bizarre twists of geometry

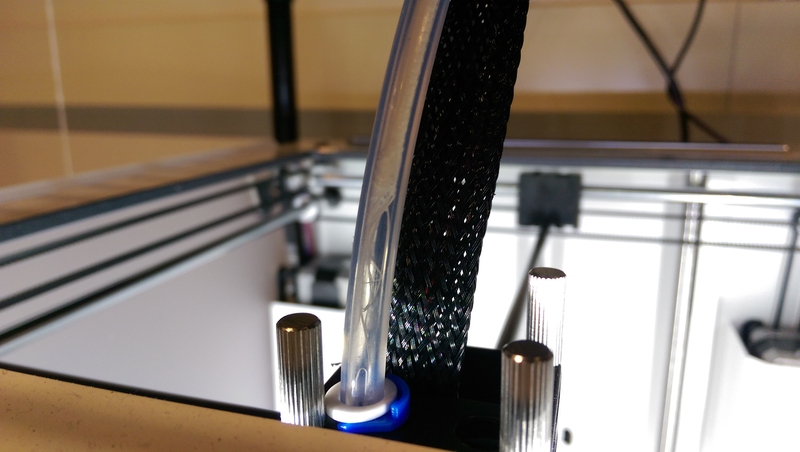

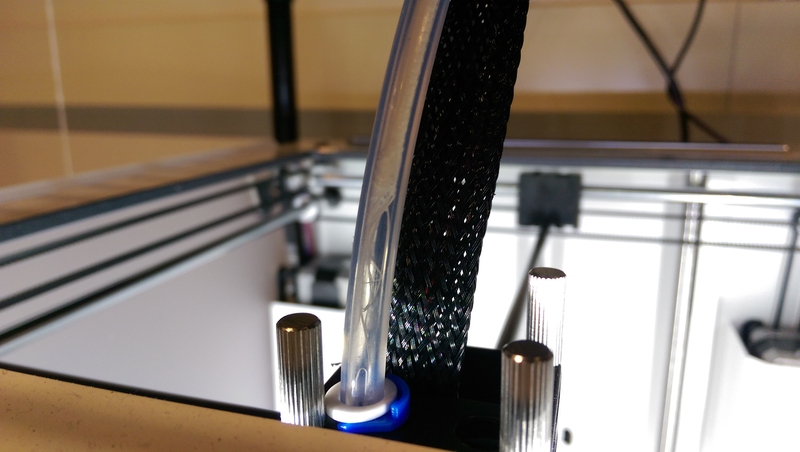

The week mostly taught me about the machine itself and quirks that happen when printing. Initially the bed wasn't warm enough (or someone before us had clogged the feed of material). This is what it looks like when this happens. The solution was to heat the element up to as hot as configurable until it loosened and then cut off the excess.

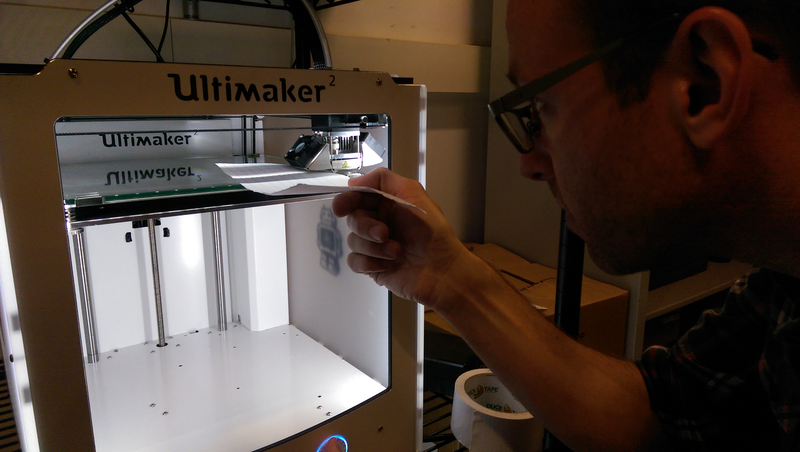

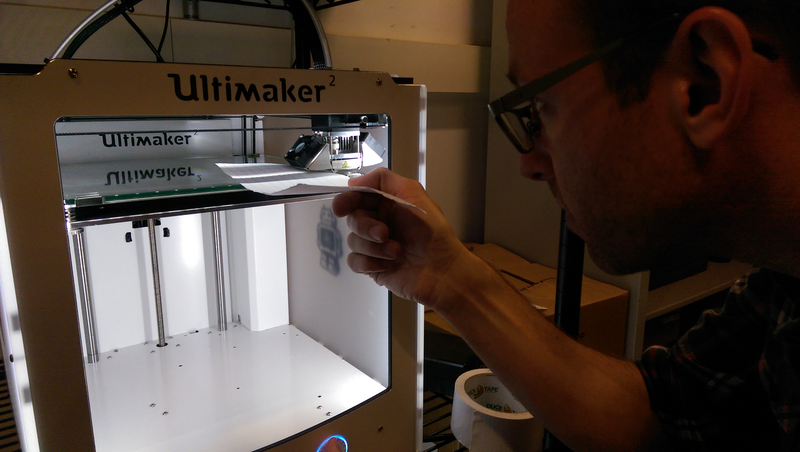

Double-checking that the bed was level with a piece of paper for tolerance/clearance.

The clogged head becoming free.

We used Ultimaker to prepare the object file that came from Antimony to ready it for a job on the printer.

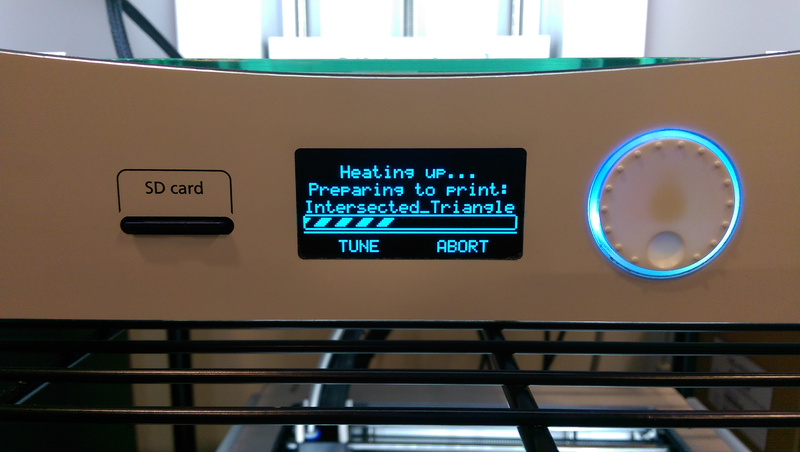

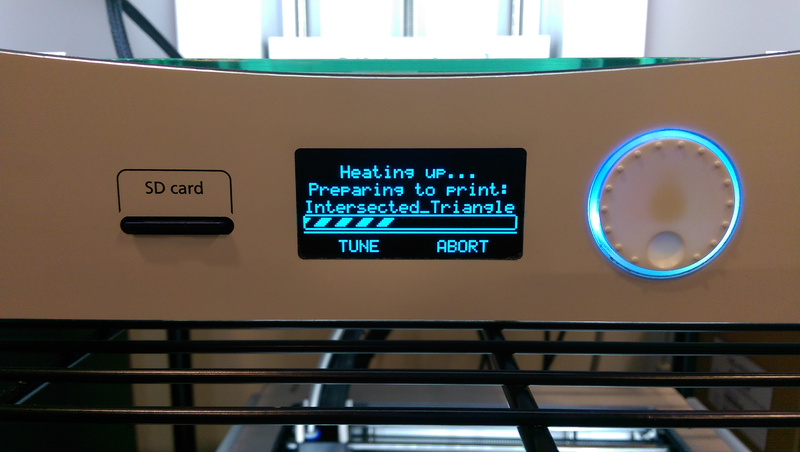

You use a USB key to transfer the final job file from Ultimaker software to the machine itself. The interface conveniently displays the job name, though it is important to realize that it will truncate it and make it hard to tell if you have your first or second version for instance.

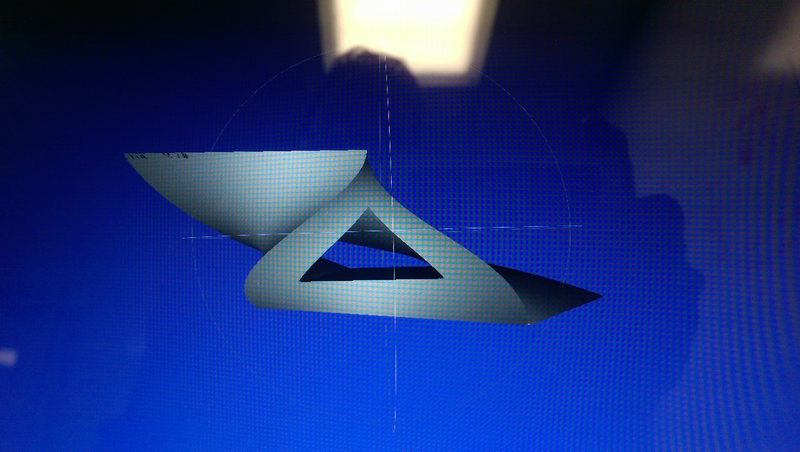

The modeling in Antimony was quirky and difficult, but ultimately came close to what I wanted.

The final print was centered enough that it actually stood on its own!

For scanning, a friend and I scanned each other's head. My scan can be seen here.