Modular Machines that Make

Cake Icing Machine

Cake Icing Machine

The CBA section decide to make a cake icing machine for the machine building assignment.

I was in the effector team - Our job was to design, build and attach the arms and the center piece to the frame. The end effector would be the tongue used to lick the machine. Besides, I also helped out with the frame team to mill the mold for the base -- that was use to make the hydrostone base. I

In the effector team, my main role was to design, calculate the length of the arms, cut the screw threads to those sizes and then fit it in the machine.

The CBA section of MAS.863 2015

As mentioned in the abstract, I helped out with two things:

1. Effector team

I was responsible for designing the arms, cutting and attaching them to the end effector - the toungue and the towers - the frame. To calculate the arm length, I looked at online manuals for the delta bot, figuring out what should be the ideal length for the arms. Mainly, what I was looking for is that the arms should be the size that they should be able to cover maximum area on the base. The frames are of unusual height as compared to the original delta bot. They are not tall enough to cover the entire base area. If I make the arms too long, they would be able to reach the base of the other frame but, would not be able to reach the base part closer to the frame they are attached to. If I make them too short, then they wouldn't be able to reach to the bottom of the other frame. So, to reach the optimum height, I calculated the average of both these extreme cases. Specifically, I used the following algorithm:

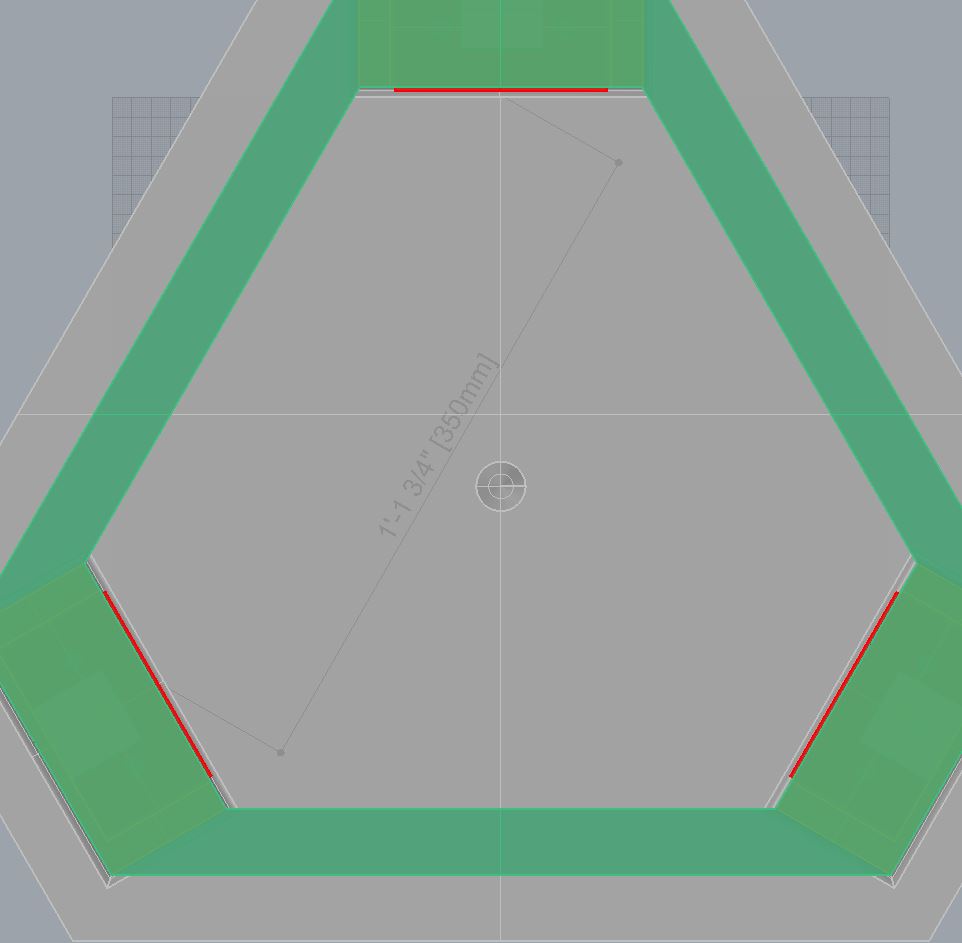

Horizontal length between the carriages = 350mm (Figure 1)

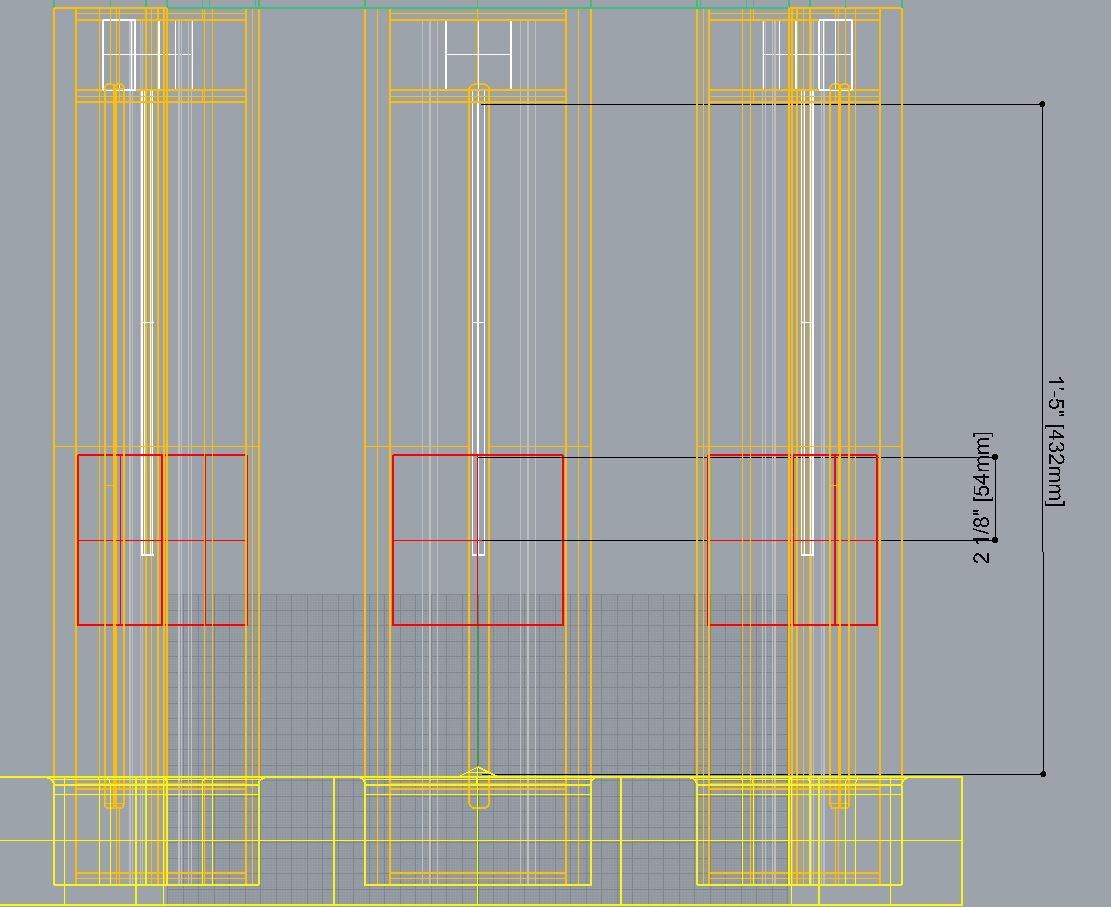

Length from topmost position of the center of the carriage and the base = (432-54) = 378mm (ref Figure 2)

Assume the height of the cake is between 3 to 5 inches (x mm) (ref: Google images)

The vertical height should be 378 - x

The length of the arm = average length - tongue spacing - carriage attachment assembly length

= (350 + 378-x)/2 - 25.4 - 25.4

~ 313 - height of the cake/2

Assuming height of the cake is 4inch ~ 100mm (average height)

~263mm

~10 1/4 inches

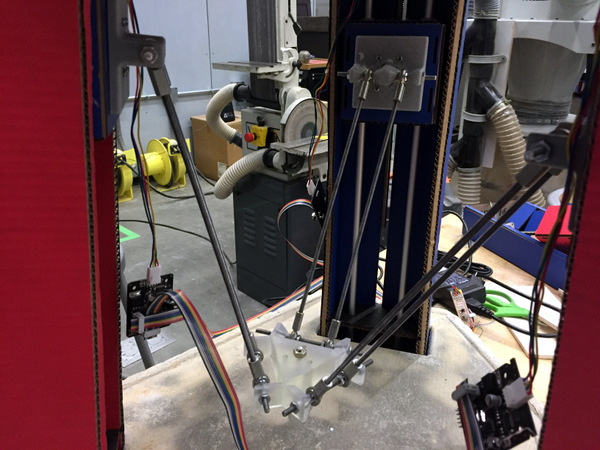

Once I calculated the length of the threads, I procured the thread of 6 feet length. I used the metal saw in the lab to cut it to the requisite length and attach them to the carriages and tongue with the help of Eric and Caroline (the effector team).

2. Frame team

Kim was responsible for making the mold for the hydrostone base. As she was inexperienced with using shopbot, she reached out to me to help with the shobot. She and I configured the shopbot to make the foam mold the frame team designed. We stacked three foams on top of each other to make the requisite height and then cut it with the shopbot. It took about 5 hours to complete--much greater than our expected time.

Figure 1: Rhino model of the machine - viewed from top

Figure 2: Model viewed from side. The read ones are the carriages.

Figure 3: The machine after attachment.