CNC Cutting

For CNC Cutting week, we we’re tasked with designing a press-fit construction kit out of cardboard. The kit was supposed to be able to be rearranged in creative ways to make new forms, like legos or knex. For my project, I wanted the press-fit kit to be fun to arrange in different ways, but also have intended form.

Tools+Skills

- Universal and Epilog Laser Cutter

- Adobe Illustrator

- Adobe Photoshop

- Solidworks (with design tables)

- Roland Vinyl Cutter

At first, I was inspired to make a box or a ball, but then started looking at some more interesting shapes. I started looking at modern art forms and came across the amazing geodesic domes from Buckminster Fuller. His art inspired me to make a truncated icosahedron.

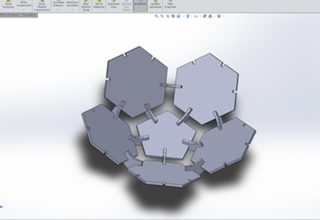

A truncated icosahedron is a lot like it sounds, an icosahedron that has had all of its vertices truncated. This leaves a 32 sided object that contains 20 hexagonal faces and 12 pentagonal faces, just like a soccer ball.

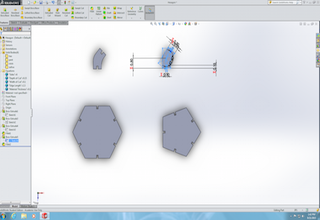

I knew that given the fine tuning that would occur later, it would be smart to design my model parametrically. For this, I chose to design in Solidworks using the design tables to define dimensions and global variables parametrically.

I designed my four shapes: a hexagon, a pentagon, an angled link for between pentagons and hexagons, and an angled link for between hexagons. In the models, the edge length, cut width, cut depth, part size and material thickness are all linked parametrically so design changes propagate based on changes to the model or table.

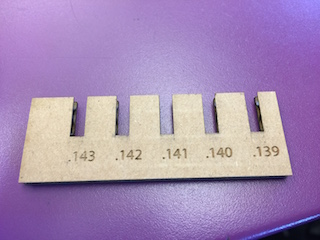

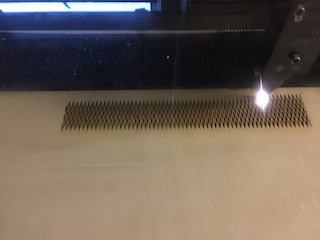

Before cutting out any of the designed parts, I first wanted to figure out the right size for the intersecting slots, because I knew the slot width in particular would have to be narrowed in on based on the exact material thickness. So after measuring the material with calipers, I designed two comb-like test pieces where I could test different slot sizes quickly until I found the right size.

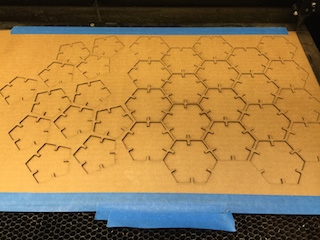

Knowing the right size for the slots, I went back into Solidworks and easily made the changes. I then was ready for my first test. I cut out one 'set' of pieces on the laser cutter and tested their fit. I correctly anticipated that it would be difficult to tell the difference between two different angle pieces, so I rastered indicators on them.

The slots fit great, but I realized I hadn't made the angle pieces long enough, because the face shapes were hitting each other instead of seating fully. So I went back to drawing board, and after a couple tries I found the right geometry.

Confident that I had the right geometry, I was ready for a full production run. The full truncated icosahedron would require 20 hexagons, 12 pentagons, 60 pent-hex angled connectors, and 30 hex-hex angled connectors.

Assembling proved to be a bit challenging, but overall I was very happy with how it turned out.

Bonus Kerf Bending

I had still wanted to use kerf bending hinges so I decided to design and cut out two kerf bent designs. One was for a desk lamp design that would double as a nice headphone holder. All components in the lamp are laser cut (acrylic and two thicknesses of plywood) and the kerf bending is incorporated into the thin plywood that wraps around the lamp

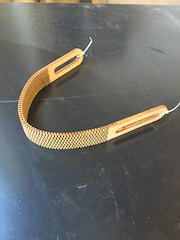

On the 3D Printing week, I make a new design to replace my headphone headband, so I thought I might try doing it with a laser cutter as well. I used kerf bending to create a headband that could mold to a headband shape and also played around with how to create a rigid cardboard headband.

Bonus Section: Vinyl Cutting

In addition to laser cutting, I wanted to use this week to do some vinyl cutting. Using the same design, I cut out two different stickers. For a new Macbook decal, I used the vinyl cutter to cut out four different colored sections fo the same design, which I then had to then reassemble into the correct design on transfer paper, before transfering to my Macbook

On the second, I used the Roland plugin for Adobe Illustrator to generate registration marks around my design. I then printed the design on label paper. Loading the paper into the vinyl cutter, I had the cutter scan the registration marks to locate the image on the paper and then cut around the design to create a sticker that I could put on my water bottle.