Large Format CNC Machining

This week's assignment was rather simple: make something big. Using a large shopbot we could make anything out of 1 sheet of 4 x 8 OSB.

Tools+Skills

- Solidworks

- PartWorks

- ShopBot

Bike Rack

Had this assignment come at the beginning of the year, I had many things I would have made. Perhaps a desk for my room or a table for our living room, but I unfortunately already bought all those things. So instead, I decided to build the one thing our landlord had promised us, but had not followed through on: a bike rack.

I wanted to make a bike rack out of as few pieces as possible. Given that a bike rack needs to be 3D to hold up a bike and OSB is not suitable for living hinges, I knew the goal would be to make a bike rack out of 2 pieces. Also, given only one 4 x 8 sheet of board, I quickly determined that the size of the rack would be greatly restrained. I started by sketching out a potential design layout in my back yard and then started experimenting with side profile designs.

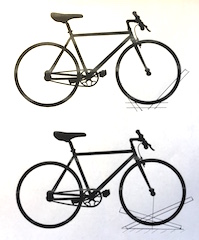

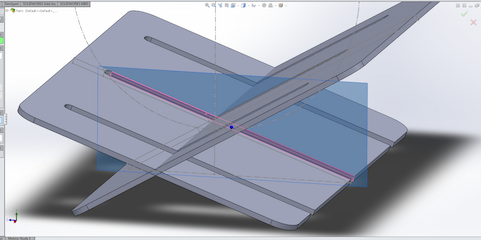

I decided that I really liked the X shaped rack, because of its simplicity and ability to keep the wheel off the ground. I chose to lay out a bike rack for three bikes (for the three bikes that belong to my apartment) and roughly estimated that bikes could be comfortablly put 14in apart side-to-side. During the training for this week we learned to always over estimate how much material you leave of the OSB, so I decided for the first prototype I would not try to do any thin features and instead kept things thicker. I modeled the two pieces in Solidworks, by setting the two profiles and thicknesses and then intersecting them to create gaps for assembly.

After designing in Solidworks, I exported the two pieces as .dxf outlines and brought them into PartWorks to create the tool paths for the 1/4" end mill. I chose to design in the fillets in tight corners for the 1/4" end mill, because the added material in the interior fillets needed to be factored into the size of slots for assembly. Since the two parts were relatively simple, tool path planning was relatively simple. Quickly, I was able to set up the ShopBot to mill out the outlines and assembly slots for the bike rack.

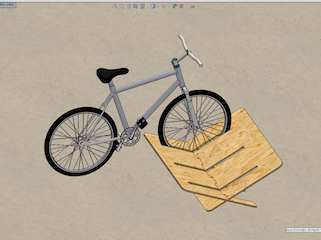

With just a few minor complications, the pieces came off the machine true to form. The OSB material was a mess to work with, many edges were frayed and splintered, requiring an extensive cleanup and sanding. But after clean up the two parts fit together as intended.

I brought home the bike rack and set it up in my back yard. It works great for keeping the bikes upright, but tends to sag a bit more than I designed for. This is due to differences in thickness of material and how warped the material is. Also, I was not quite pleased with appearance, it is far bulkier and blockier than I anticipated. In the next iteration I would like to fix both of these problems.

Future Work

Not being fully satisfied with how the project turned out (also due to time constraint this week on my time and the machine time) I would like to continue and do something extra for this week. I am between a small end table / stool or a chair such as the kerf chair from OpenDesk. I would like to incorporate kerf bending if possible. For these projects, I would like to get nicer wood to make a quality finished product.

Transformable Objects

I have been eye-ing the possibility of making something similar to Robert Van Ebricq's Rising Furtniture

However, I just went to a talk by Chuck Hoberman and it has inspired me to look into other transformable objects.