GLASS from Mediated Matter Group on Vimeo.

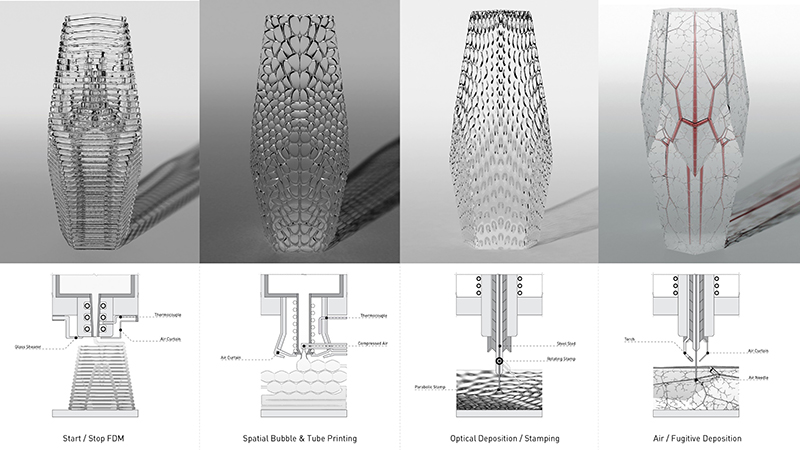

Mediated Matter's molten glass 3D printer (G3DP) has produced some spectacular forms. The printed pieces are like nothing I've ever seen before, yet the machine that makes them, in being obliged to do so, is extremely limited in its functionality of glass extrusion. Unlike many other materials used for additive manufacturing, glass can be all at once structure, optics, and biological containment. The excercise of developing an additive manufacturing platform for clear glass was meant to lay foundations for a jump in scale both physically and in complexity/functionality.

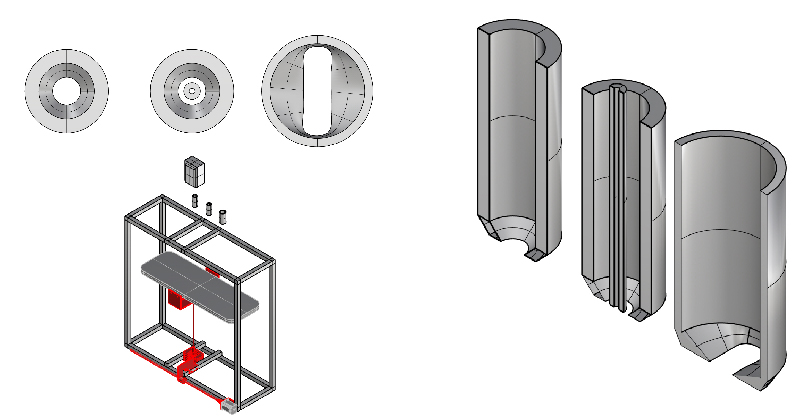

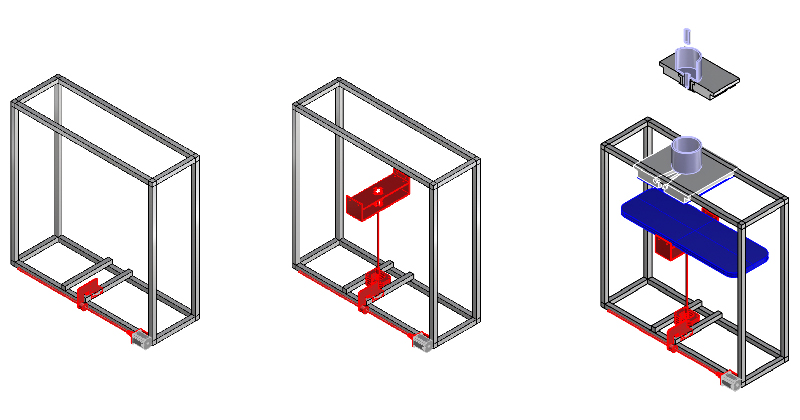

To conduct research in some of the more exotic additive manufacturing processes including a potential hybrid of blowing and additive extrusion, first we need to readdress aspects of the platform that were previously necessities to 3D printing but would now be constraints on a more variable, exploratory tool. Modularity and rigidity are key to allowing the focus to shift to development of exotic or novel nozzle technologies. Instead of larger thermal components operating in nested frames for linear motion in cartesian space, I am proposing 2, 1, or 0 axis development kit for glass printing. By removing one or more axes, and mounting a sationary extruder/printhead, we would be able to quickly replace consumables in the nozzles, crucibles, glass stock without disturbing a motion system. We also lose scale in favor of prototyping variability and precision in favor of functional extrusions.

Finally, we could potentially think about producing some of the intial parts for development kit. We can imagine slipcasting alumina for more variable nozzle geometry and coaxial nozzles for extruding with pressurized air or a metal or support material core. As a final project, the (G3P devkit) woudl allow me to tackle building modular systems from materials like aluminum extrusion, controls for linear motion systems, power circuits for heating systems, cnc machining of insulative ceramics and even molding and casting of ceramics. More realistically than all of these goals though, the project can definitely be divided easily into its parts to allow for time constraints, and can also be finished with the help of the Mediated Matter glass project team.