type S thermocouple | op amp | serial read

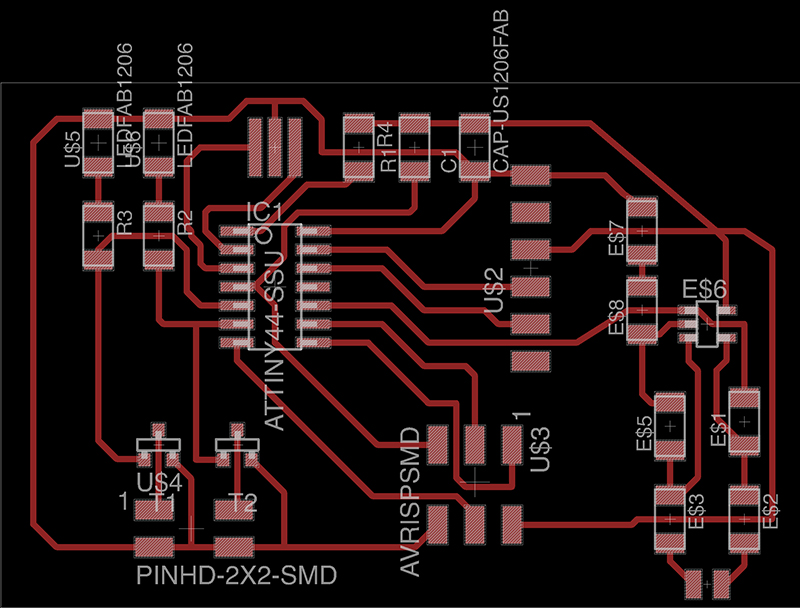

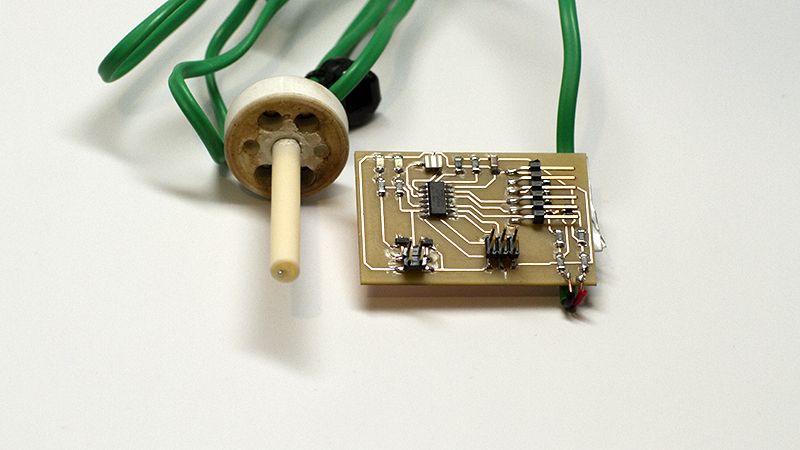

Last week I began the process of making a custom controller for a glass melting kiln. I added a way to actuate relays which could control the power the kiln's heating elements. Without knowing the temperature inside the kiln, that facility is useless, so this week I added to the controller device a way to read high temperature type S thermocouples that are capable of reading temperatures up to 1760ºC. To do so, I used the operating amplifier in the fab library, and one of the free pins on the ATTiny44 microprocessor I've been using for the board.

While it seems like a simple practice to electrical engineers, it took some time for me to uderstand even slightly what the opamp was doing, and finally I was able to calculate the gain created by a given set of resistors, and matched it to the gain required from the thermocouple. The type S devices output 0V at 0ºC and 18mV at 1760ºC, which needed to be mapped to 0V - 5V. The resistors I ended up using were 499 ohm in series with 1M ohm and 499 ohm in series with 100K ohm. This gives a gain of 201, while ideally the gain should be 268. a 130k ohm resistor instead of a 100k ohm one would get it very close, but these need to be ordered. In truth, I'm happy to keep this resistor value variable because the glass printer never reaches higher than 1300ºC so perhaps an even larger resistor would do fine. It's all just a matter of consistency in calculating the temperature from amplified voltage.

At this point, I'm able to read the analog input from the thermocouple and can therefore calibrate and read temperature. Independently, I'm able to control the heating elements inside the kiln. Finally this controller will work by simply adding connections on top of those already in place in the standard kiln controller, so that I am able to assume control from a laptop without sacrificing the safety protocols of the kiln itself. The final step, for next week, and indeed for my final project, is to create a user interface which will give control of kiln temperature directly to the user, minus the time it takes to actually reach that temperature inside the hot zone, of course.