Titanium Paintbrush

Final Project Proposal

Overview

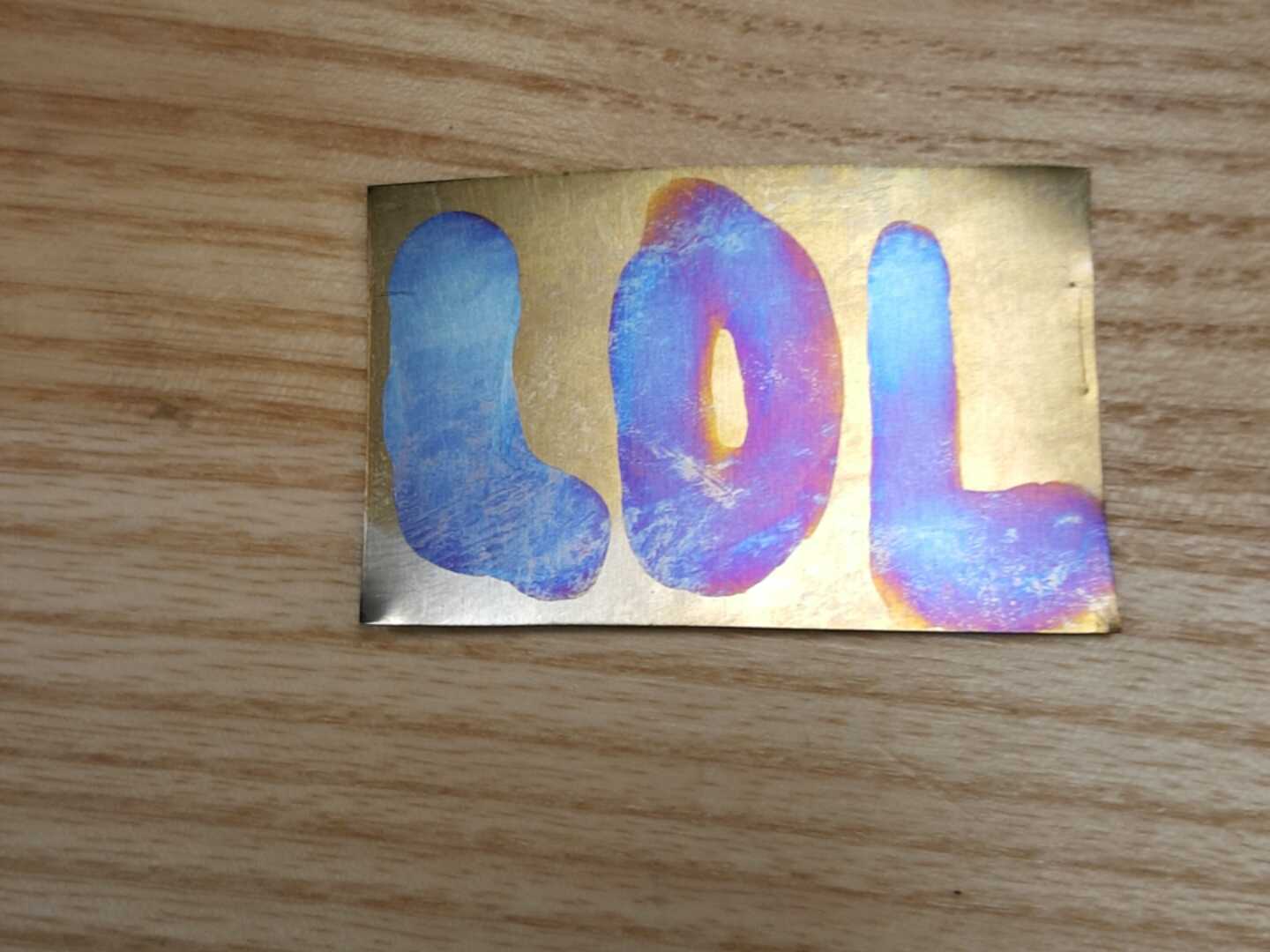

I'd like to create a paintbrush with a color knob.

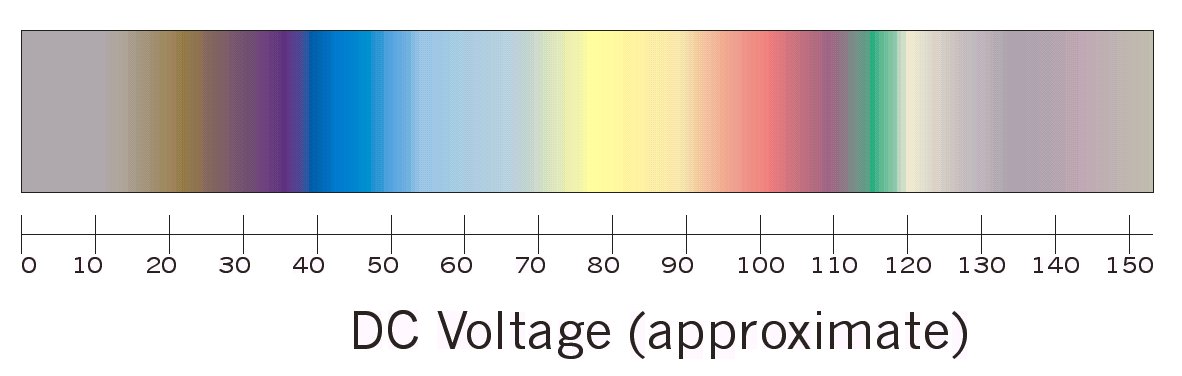

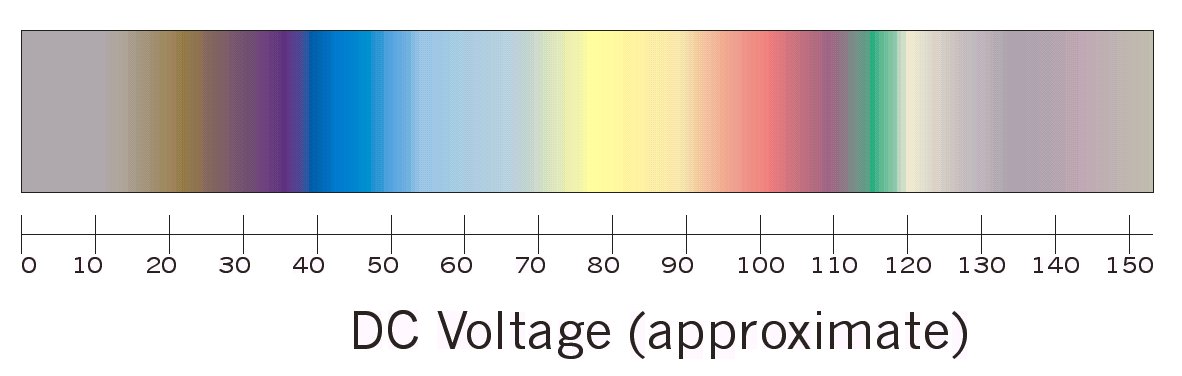

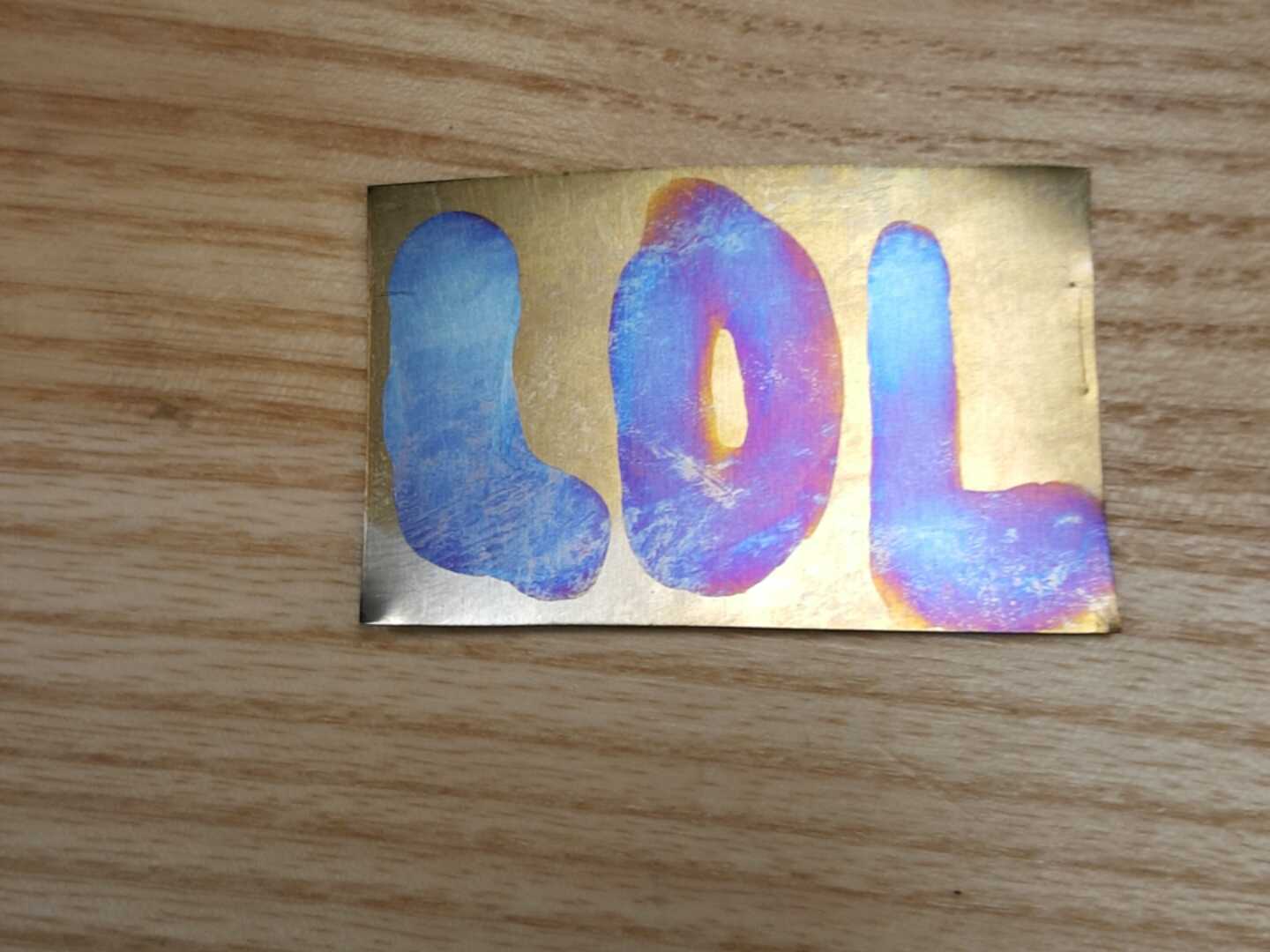

The "canvas" is thin sheet Titanium (or Niobium). The paint brush uses a mild acid and a power source to anodize the titanium canvas. Varying the applied voltage varies the thickness of the oxide layer, which in turn varies the resulting color.

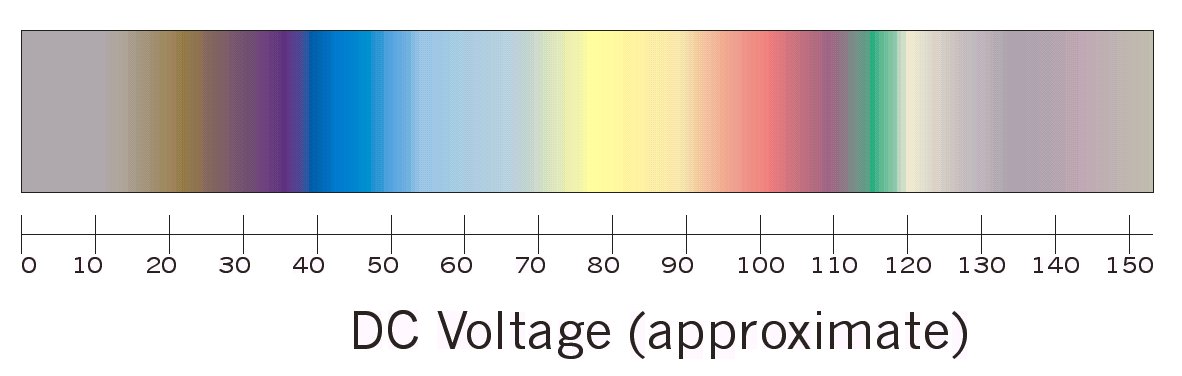

From http://www.valhallaarms.com/wyvern/titanium/anodizing.htm

Components

- Paint Brush

- Power Supply

- Easel

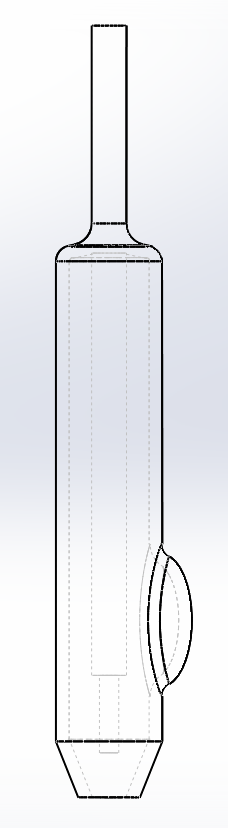

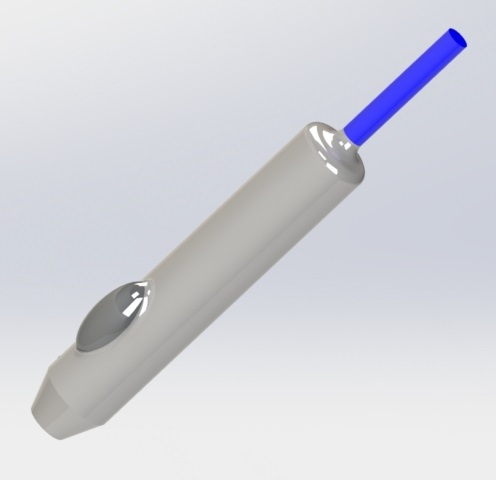

Paintbrush

The main difficulties encountered in the initial tests were controlling contact patch and preventing conductor contact.

The effective brush contact patch is actually the entire connected puddle of acid, which made it difficult to details in the initial tests. Additionally, if the conductor directly touches the work surface the anodization stops and the energy is converted directly to heat.

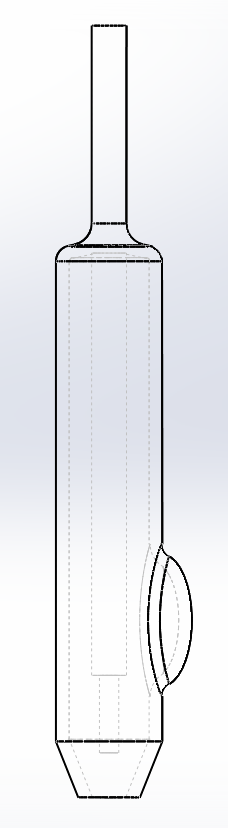

I'm currently considering an "eye-dropper" approach with an overmolded/internal electrode.

The internal volume is hollow and a flexural component allows the user to pickup or dispense acid like an eye-dropper. It is currently drawn in the same location that some mechanical pencils have their mechanism.

Power Supply

The interesting voltage range for Titanium is ~20V to 120V DC, and for Niobium ~3V to 110V. Anodizing speed increases with available current. A few quick tests with a CC-CV lab supply showed that half an amp of output is likely sufficient.

I'd like to try a flyback (or inverting?) regulator. This has a few advantages:

- 1) The input would be a reasonable midrange DC voltage - 10-20V?

- 2) There is no direct path from input to output. No accidental spot welding!

- 3) It is relatively easy to regulate current with this topolgy.

Easel

The easel holds the canvas flat, provides,

I think I'm going to hide the power supply in the easel. Unless I'm severely over-estimating the wattage requirement, the supply will be too big to hide in the brush itself, and it needs to return to the work piece any way.

Depending on canvas thickness and curvature, I could use a magnetic conductive surface as the easel back. Magnets would hold the piece in place, and the supply return would go to the entire surface.

Example