After coming up with the idea, I wanted to create something small and sleek. The cardboard pieces that we had lying around were roughly 30x17 in, so this somewhat limited the size of night stand I could make, but I wasn't planning on making anything too bulky, anyway. I drew up the design in Inkscape.

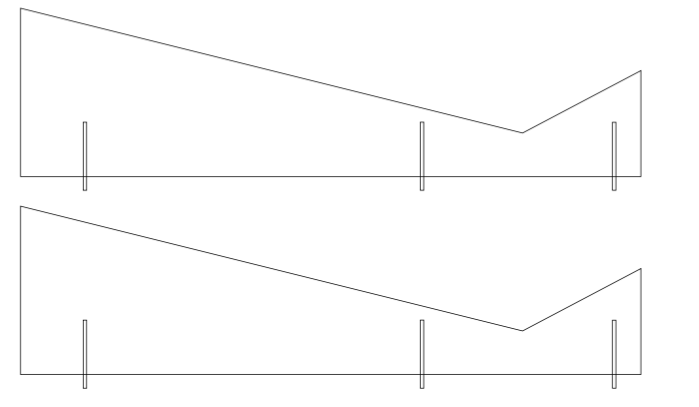

Here is the initial design I had for the legs and for the shelves

Generally speaking, I'm averse to logos as a whole, but I figured a nightside table that was unlikely to make it out of my Harvard dorm was a pretty harmless place to put a Harvard logo.

One thing that was surprisingly difficult was transferring an image from Inkscape to CorelDraw, the software that out laser cutter required. Inkscape saves images at 90 DPI, while CorelDraw at 96, so when transferring over an SVG, everything was shrunk by about 6%. I attempted to scale everything up in Inkscape by this factor, but it did not work. The image format that eventually transferred over best was a PDF, surprisingly enough.

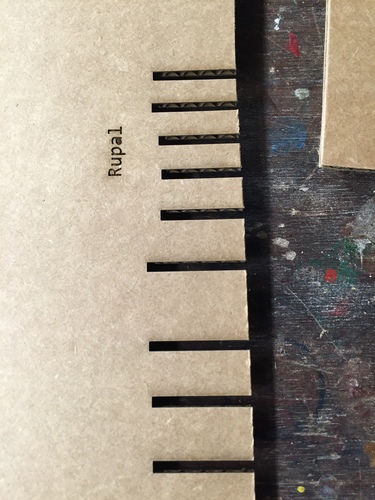

Testing out some different cuts for fits. s/o to Rupal

I had heard from many others in the class a variety of values for the best fit for laser cutters, ranging from 0.14-0.16 inches. I knew that the snugness of fit was very important to my project, so I wanted to get this exactly right. I tested out a variety of values from 0.137-0.159in, eventually settling on 0.143in.

At this point, it seemed about time to finally start cutting. I re-adjusted my holes and started off.

In construction proof of concept

After printing out my legs, everything appeared to be fairly stable. However, after letting the structure stand for an extended period of time, I realized that the middle cut was too close to the border of the cardboard to be structurally sound. At this point, I realized I must re-cut my legs.

Design flaw #1

After reducing the depth of the cut size on the legs and reassembling the table, it was time for a stress test. The table held up pretty well!

It can support a laptop! Validation!

However, there are some things I wish to improve upon in future weeks. First of all, the assembly has no error correction process, since there are only joints on one side. Thus, the legs can be set at what ever angle the assmebler chooses, and one accidental kick to a leg can change the angle drastically. I realized this when still at the shop, but by that point, we were running dangerously low on cardboard.

Coming at this from a software engineering background, I'm used to time being the limiting factor. All resources are re-usable, so planning ahead is not particularly important. The iteration cycle is generally to make your minimum viable product (MVP) and then improve from there. With physical objects, it's not always possible to imporve upon the design without starting over, which was partially the case here. This is something I'll keep in mind for later.

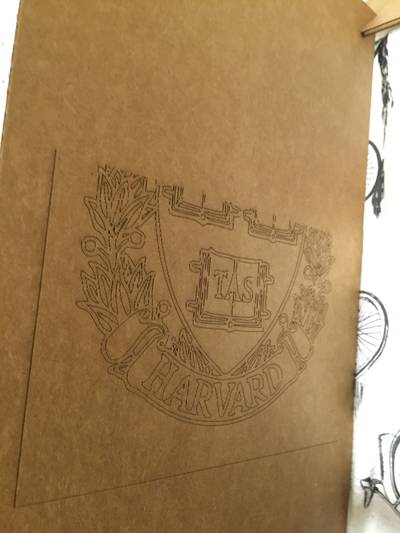

Additionally, my plan to add a Harvard logo went awry. The settings that I chose on the cutter were Raster on speed 55 and power 50 with a DPI of 50, and this ended up taking forever. It took nearly 30 minutes to print half the picture, and only ended up drawing half of it. It would have been a much better idea to have played around with settings before jumping straight into cutting. Vector/Raster would have been better, and I could have increased the speed. In the end, I ended up flipping that board over and making a small watermark.

I have seen better Harvard Logos.

However, the effort wasn't for naught. At the end of the day, I ended up with a pretty functional nightstand that is made of $2.25 of cardboard. The personal fabrication age is alive and well.