I noticed some Romanesco in my CSA last week. I was going to either scan it, or directly cast the mold from it, but I accidentally cooked and ate it. Oops. Its soft, nutty flavor lands somewhere between cauliflower and broccoli... Tasty and mathmatical!

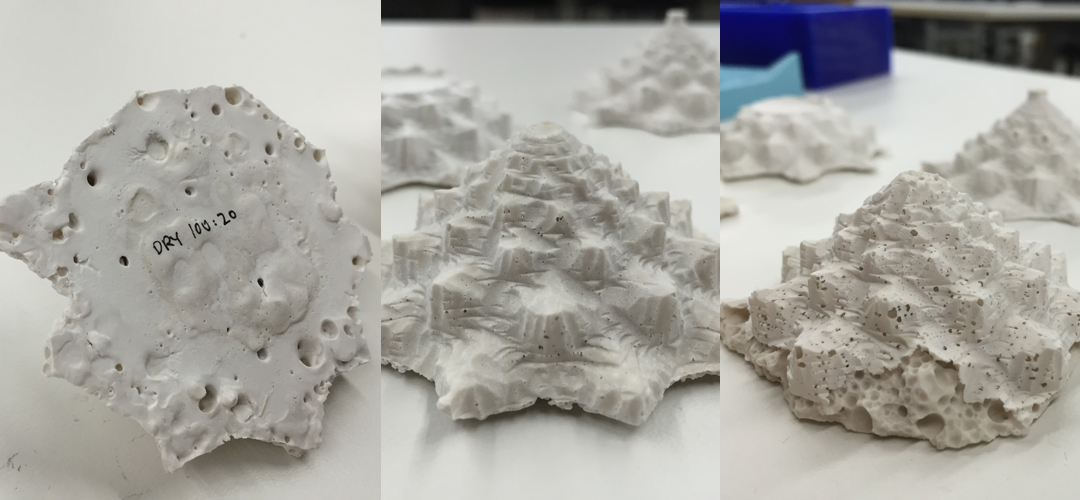

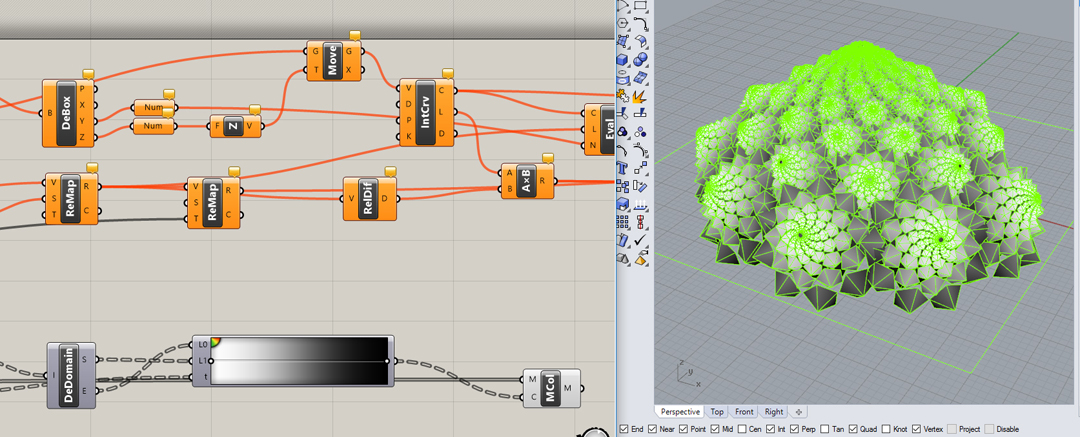

Grasshopping comes in handy for parametric modeling. Using a log spiral to place cones, I quickly subdivided the cones by instantiating the entire structure on each cone. I initially did this twice to create the fractal. With so many open cones straight out of Grasshopper, my mesh became too time consuming to prepare as a solid - so I reduced the recursion and cleaned it up as a water tight mesh.

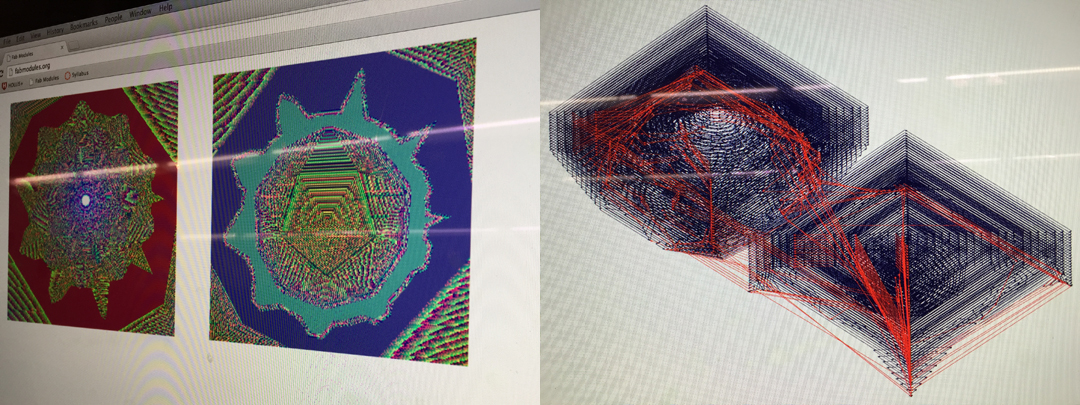

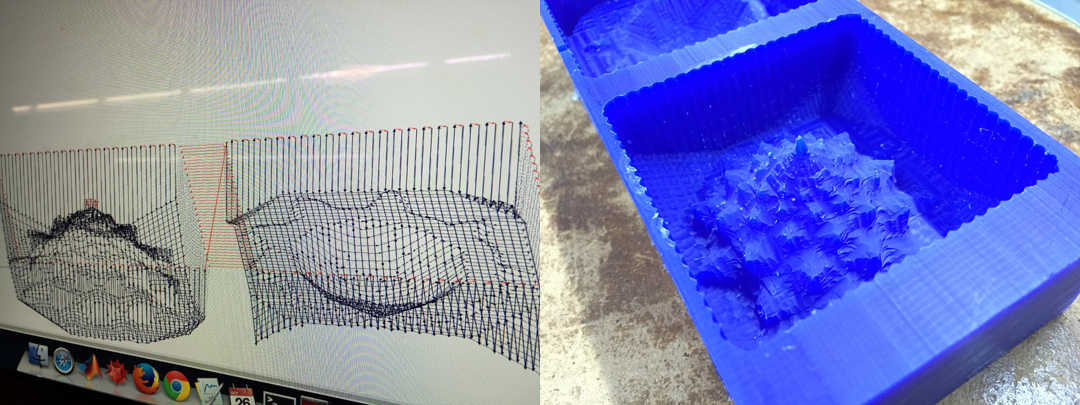

FabModules is easy-peasy to use. I imported my brocooli STL, which was converted into a heightmap; from which the 2.5D path was calculated for rough cutting.

I actually like the way the rough cut topography looks (better than the finish cut).

The tool paths of the finishing cut are in 3D.

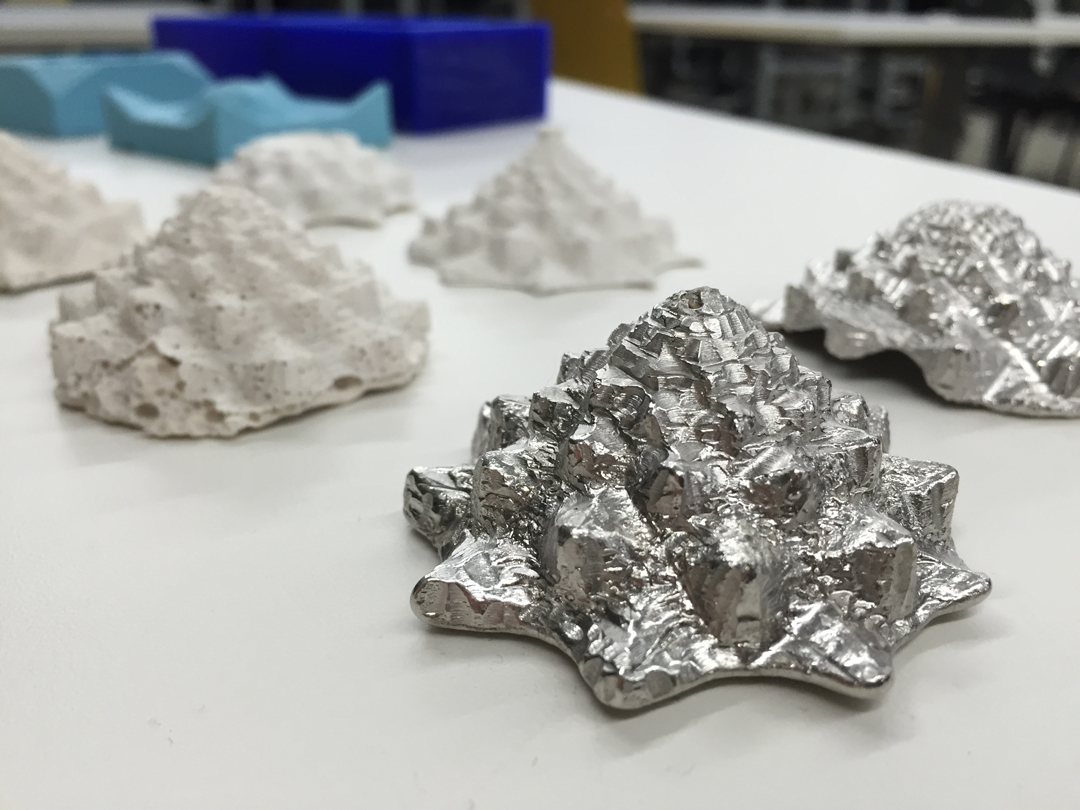

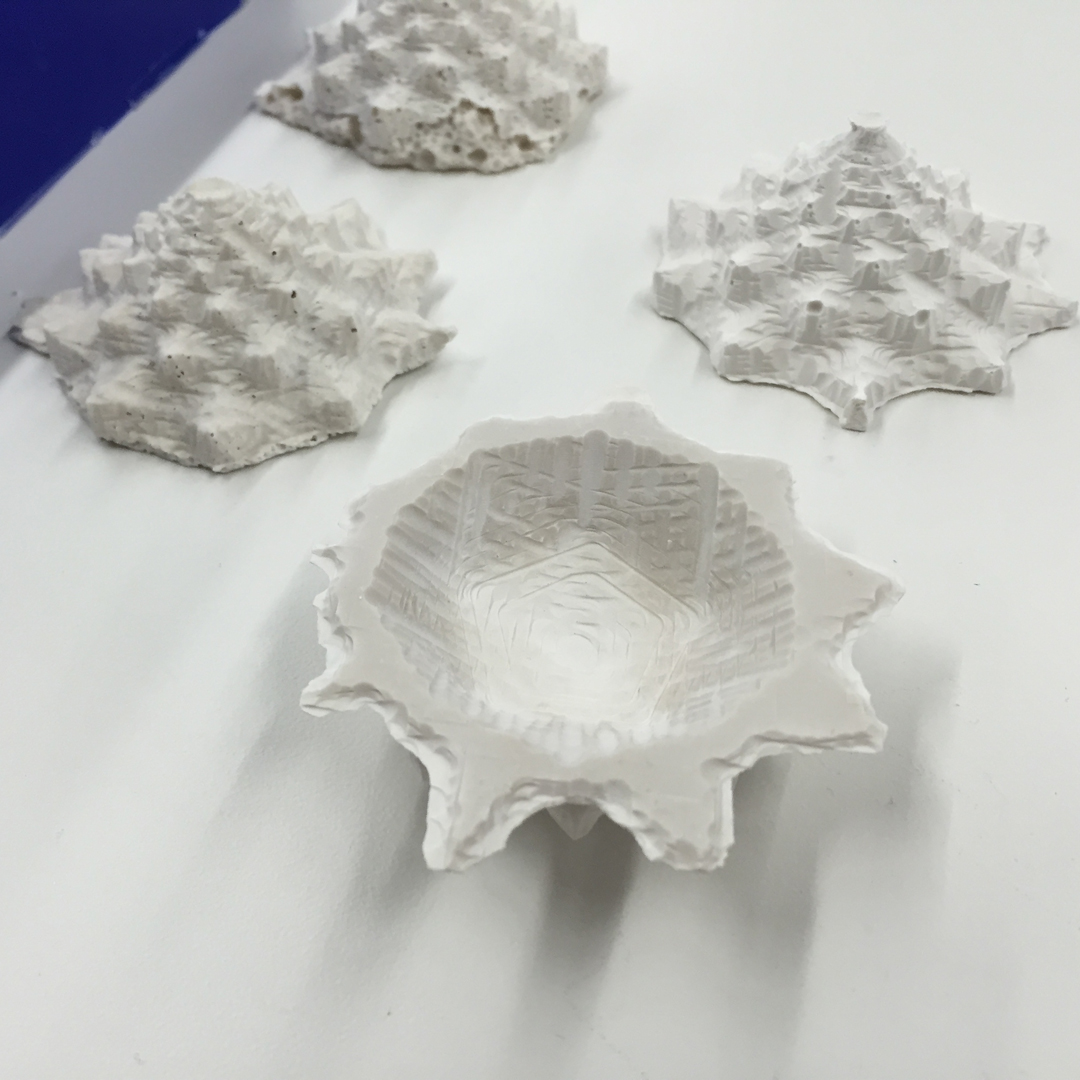

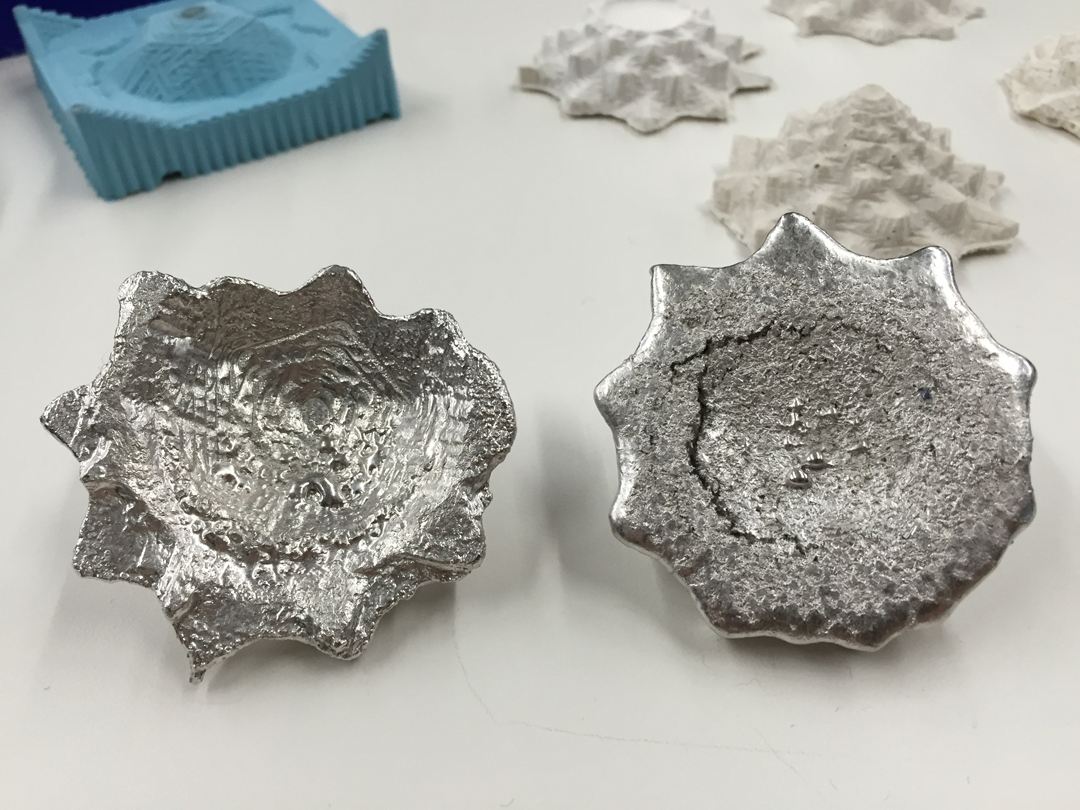

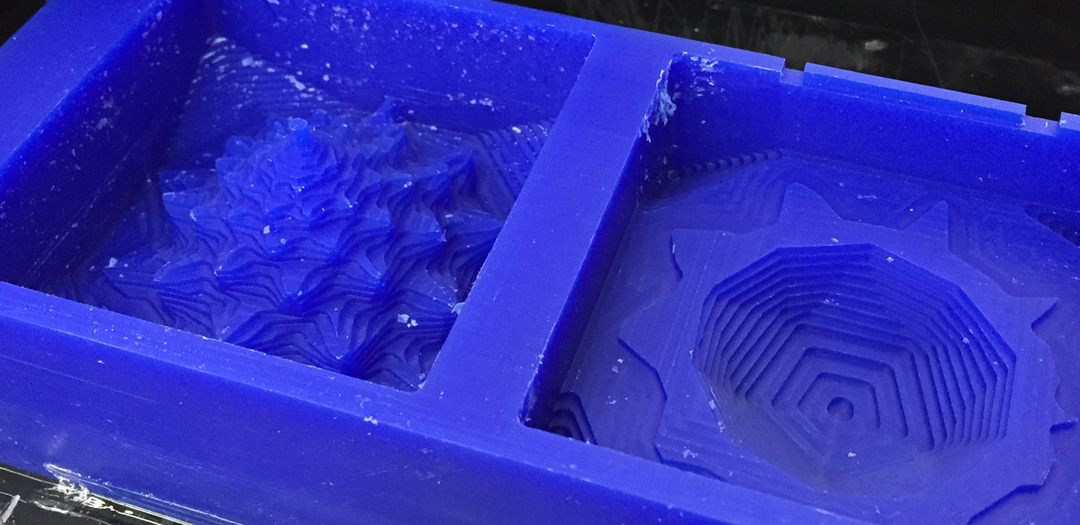

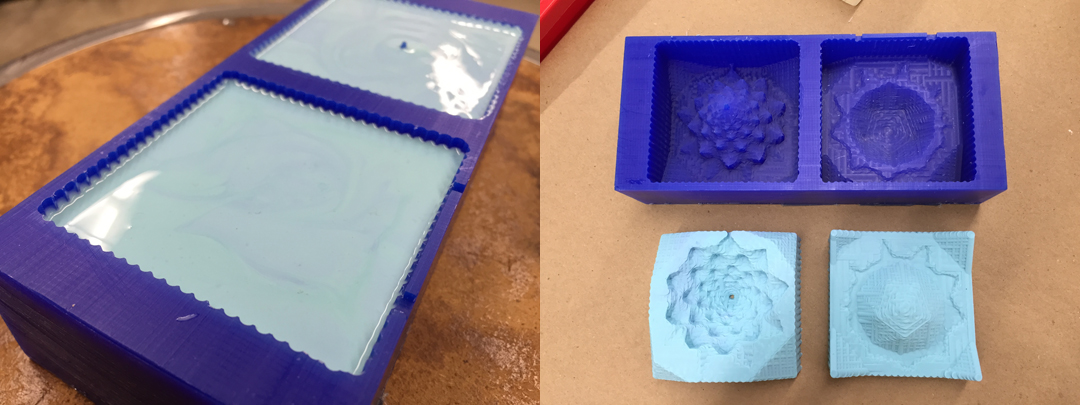

Making the negative mold in OOMOO. A bit messy, but it set and demolded beautifully.

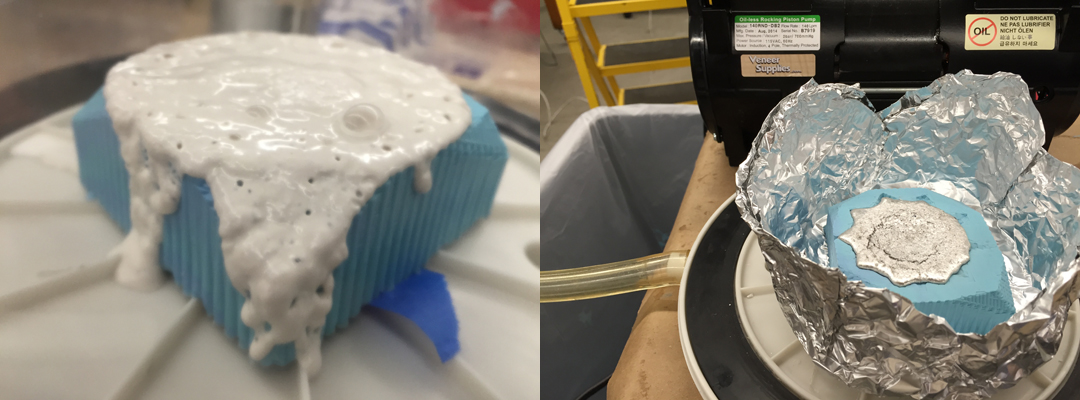

I went to Corning Inc. a few weekends ago, and becamse fascinated with glass art. How do the artists control their air bubbles?

I tried putting my molds in the vacuum as they cured... I also tested this with the bismuth+tin alloy. Can bad things happen when you put liquid metal in there?