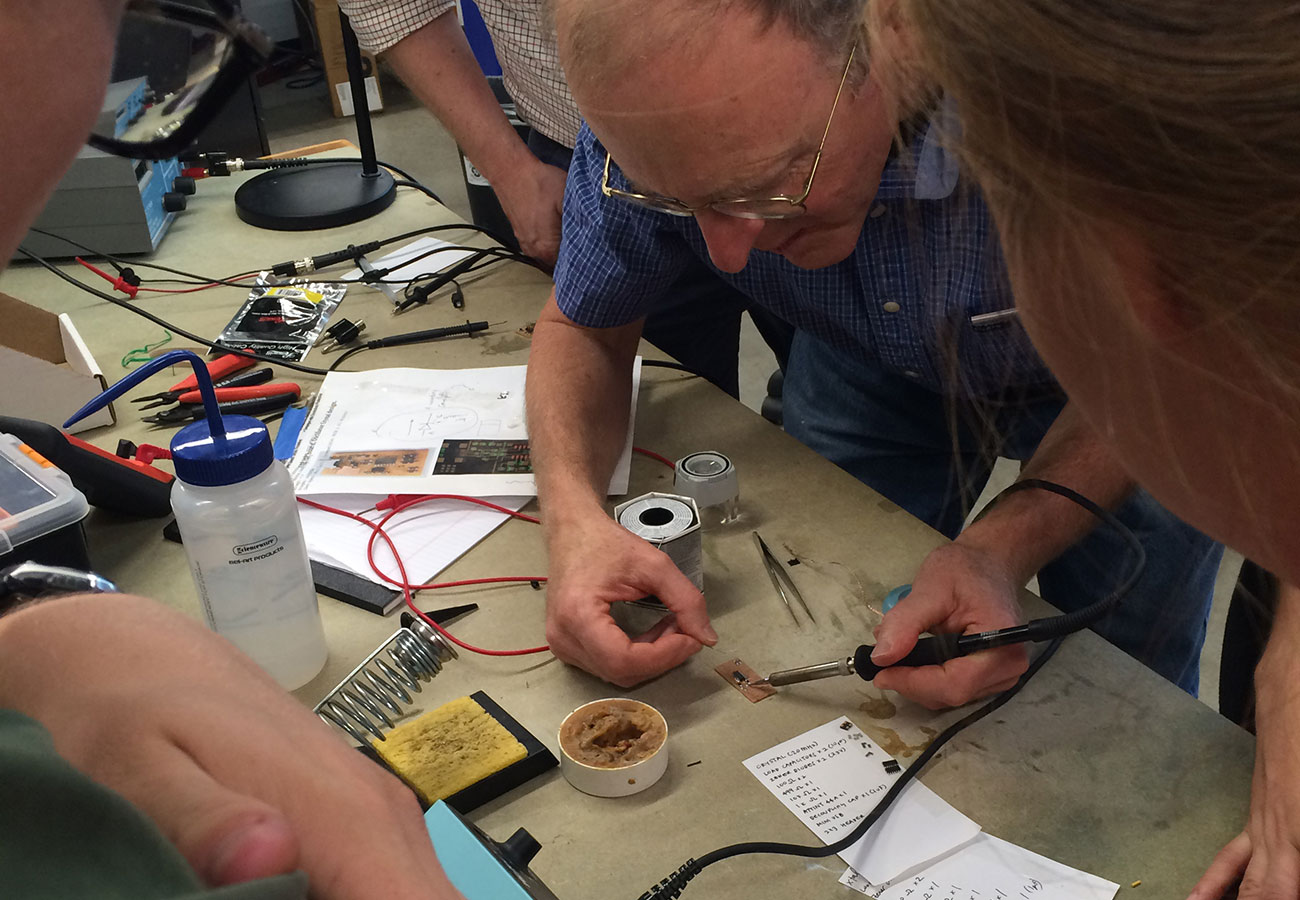

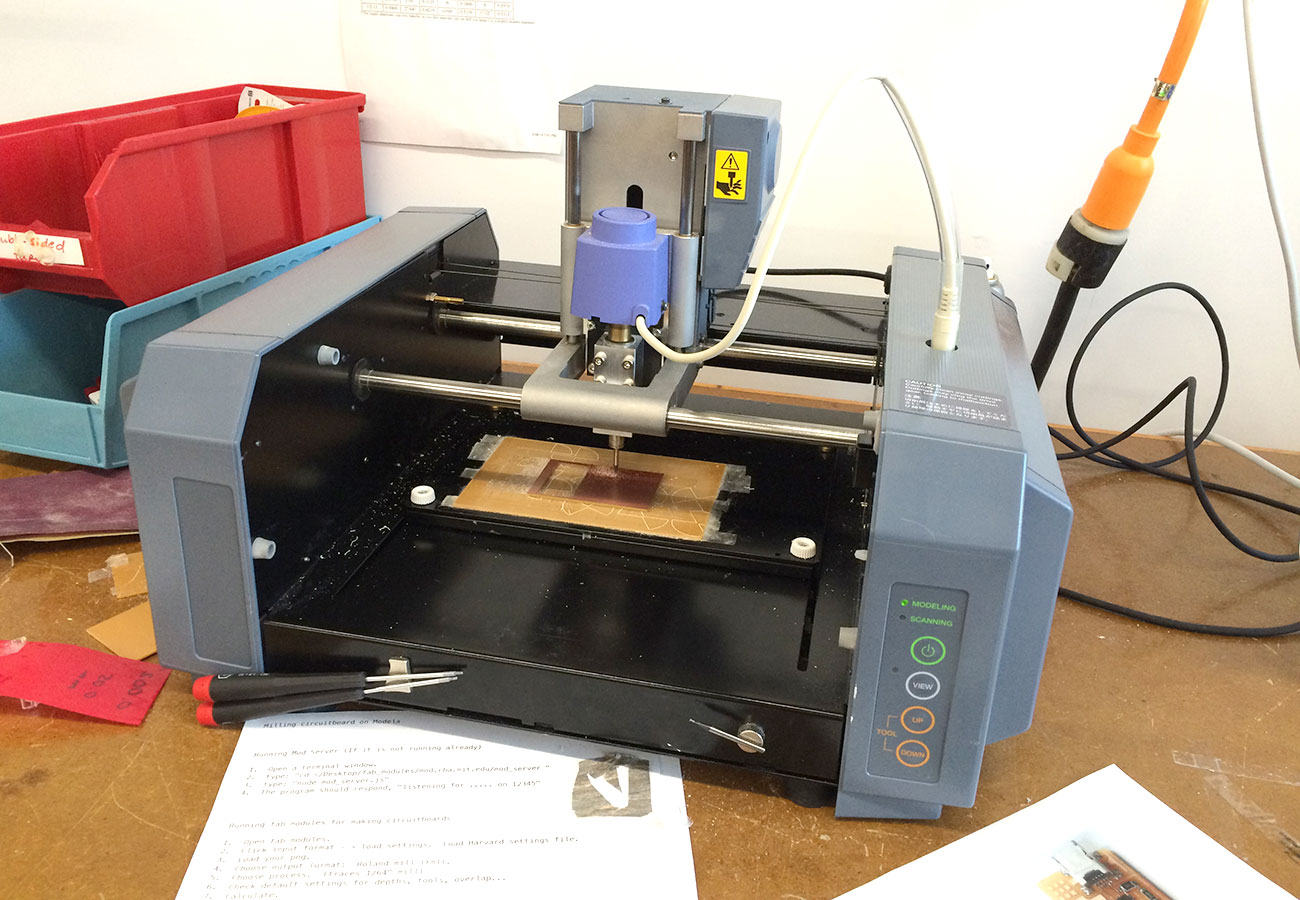

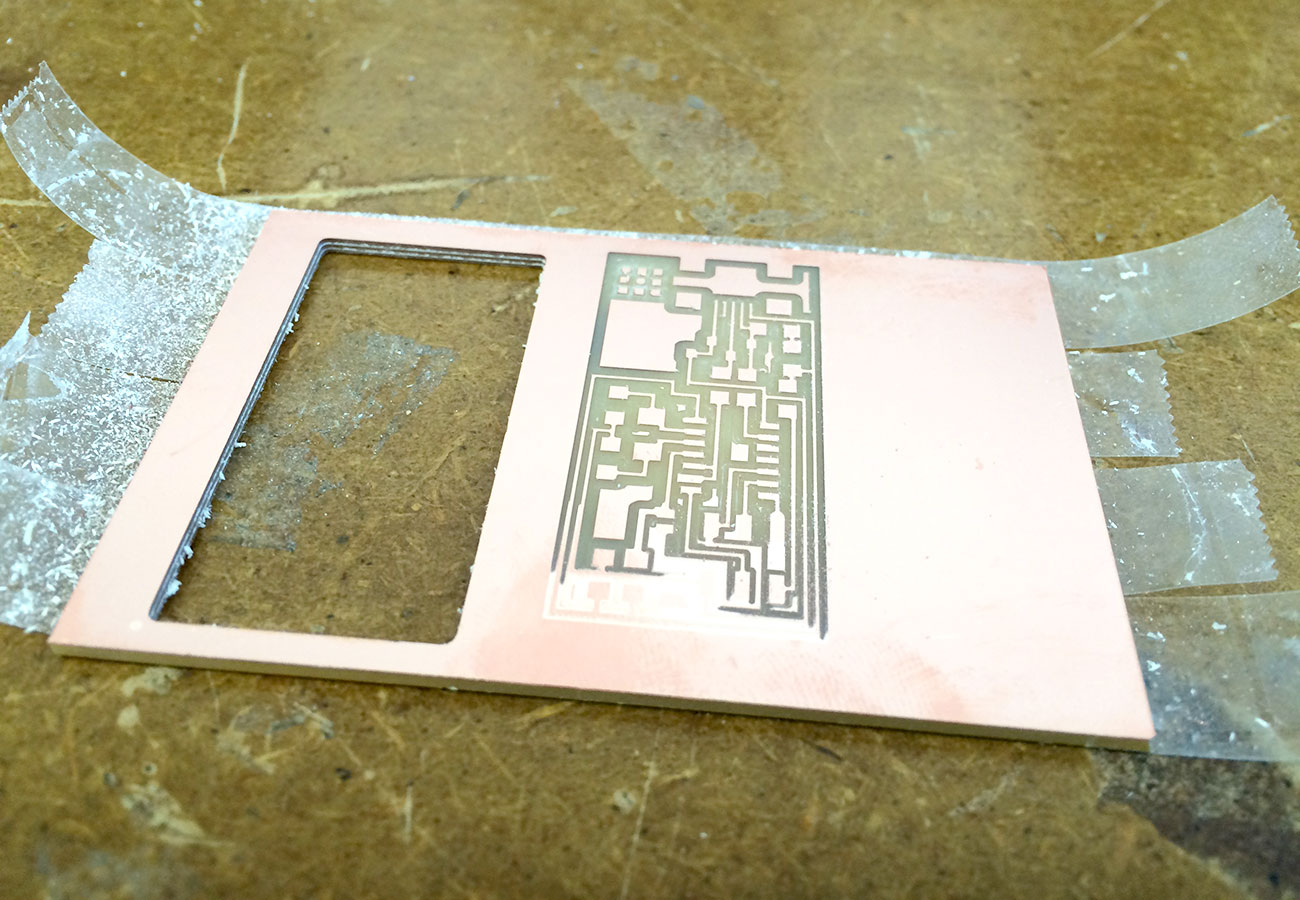

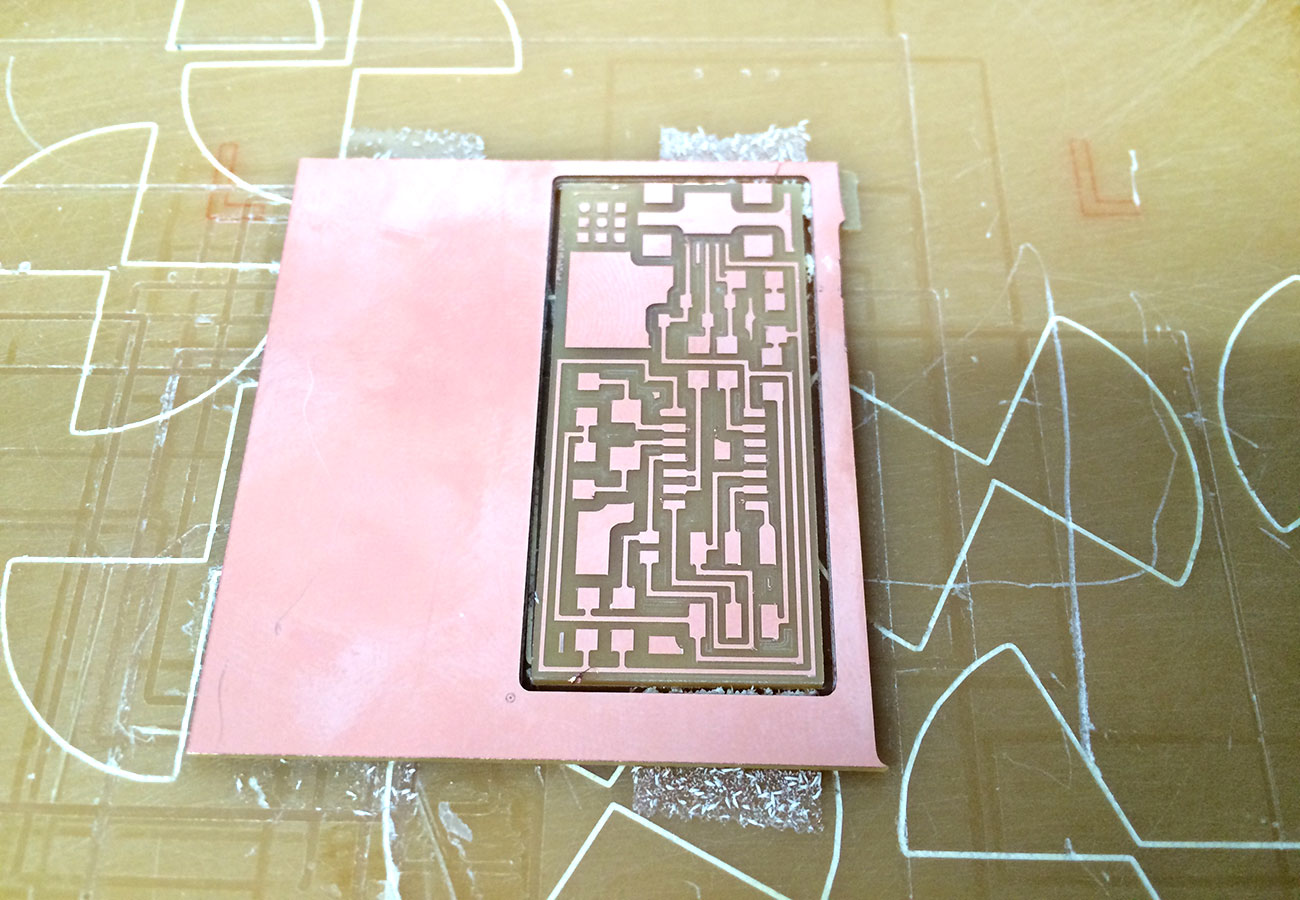

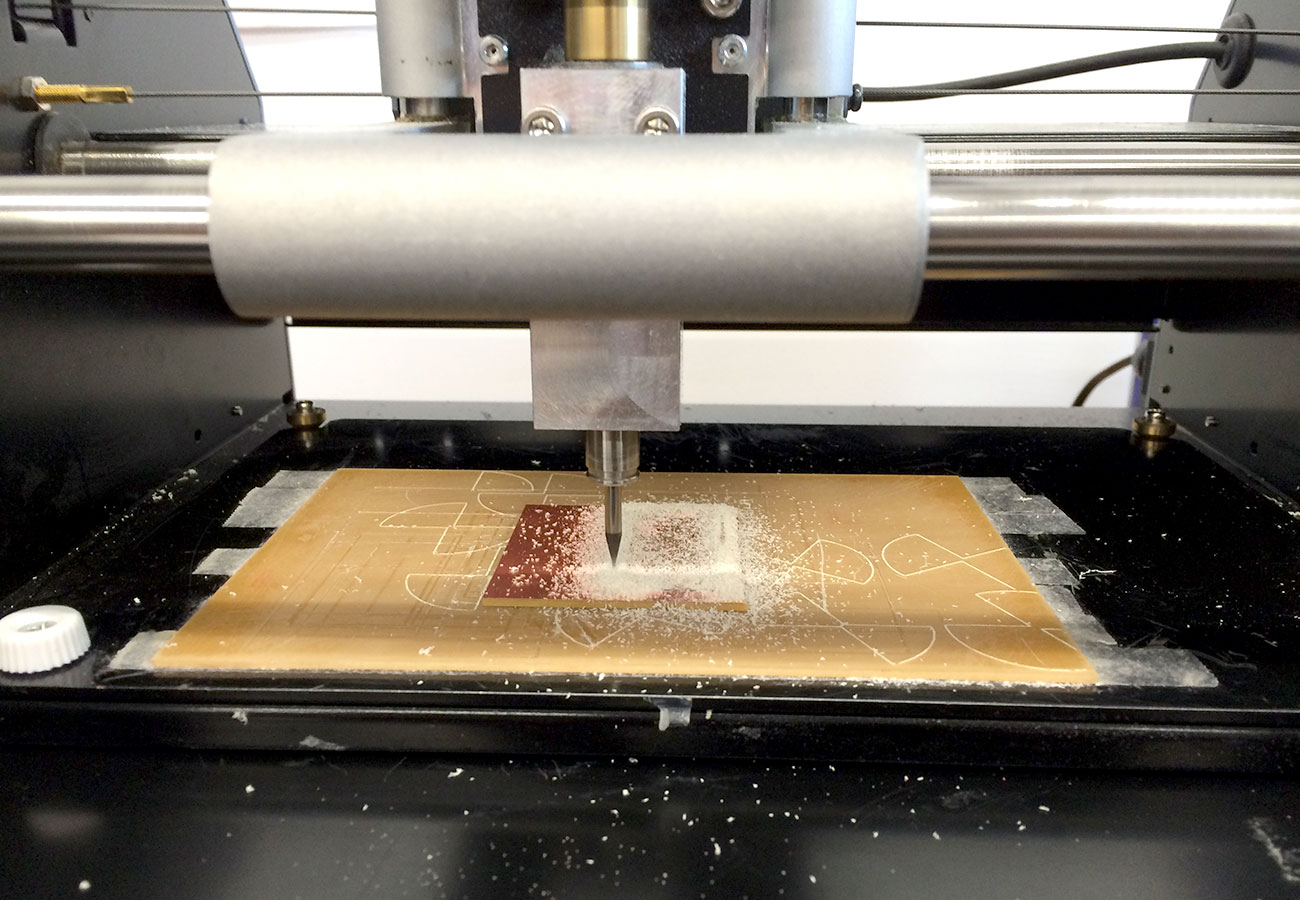

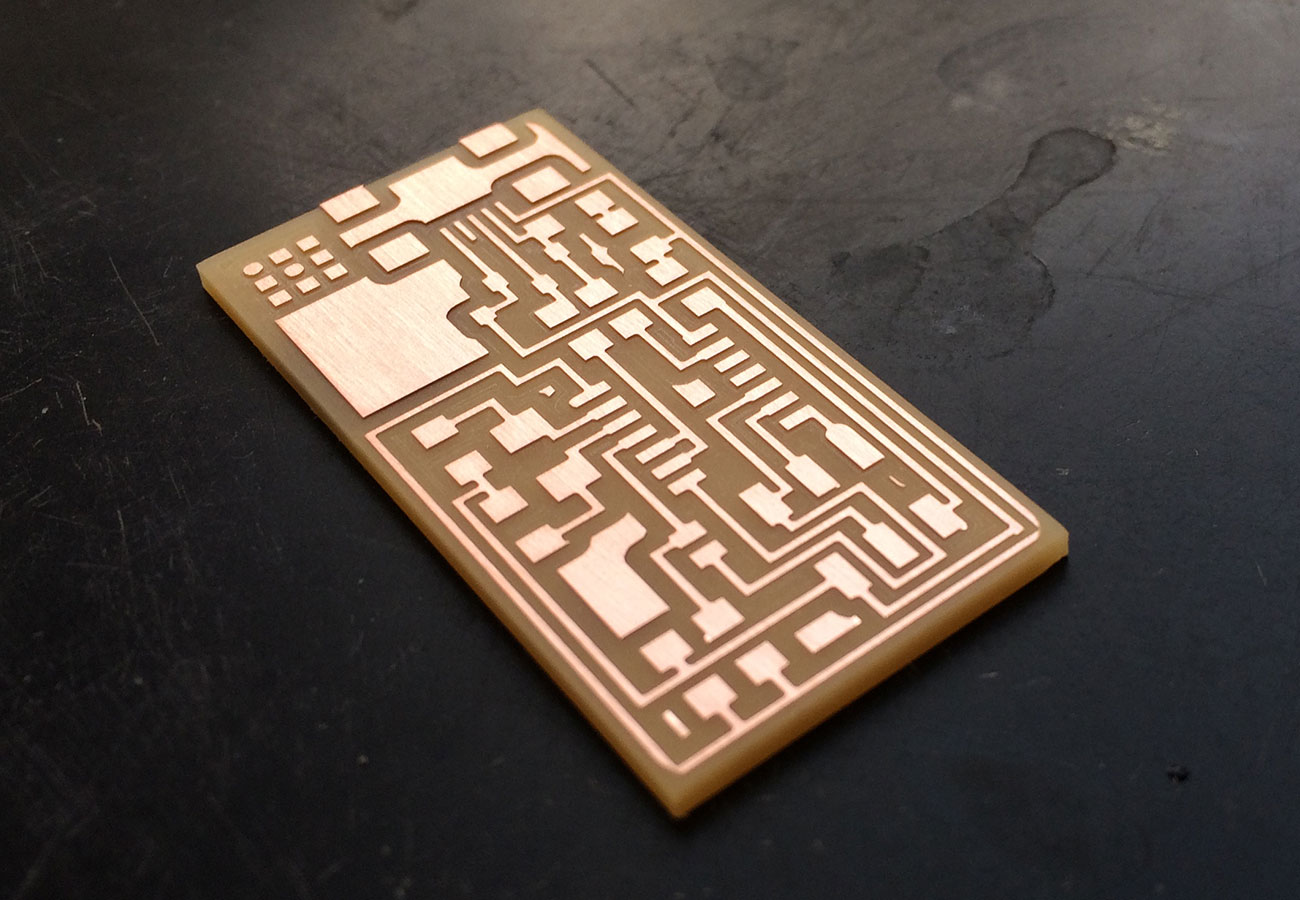

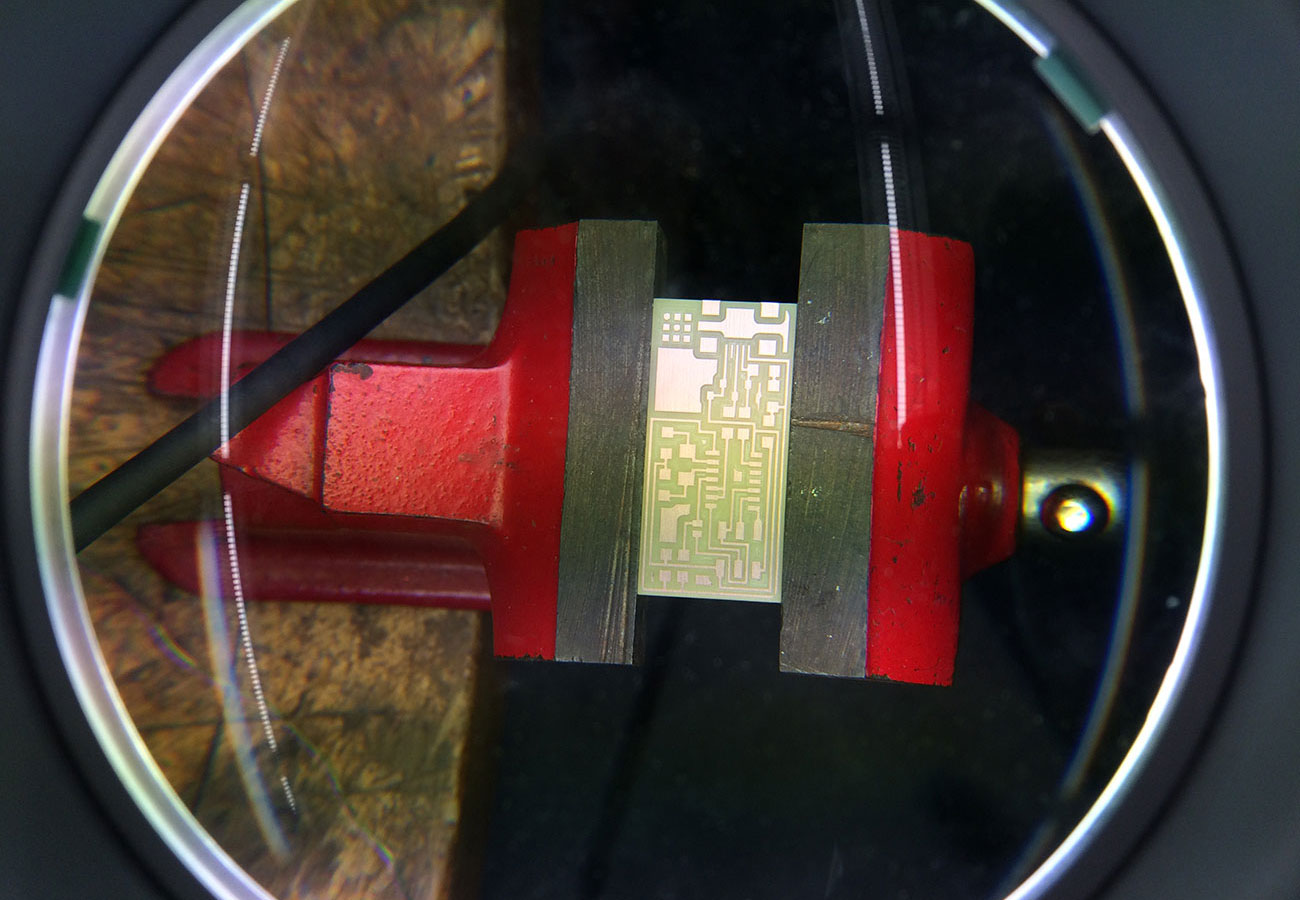

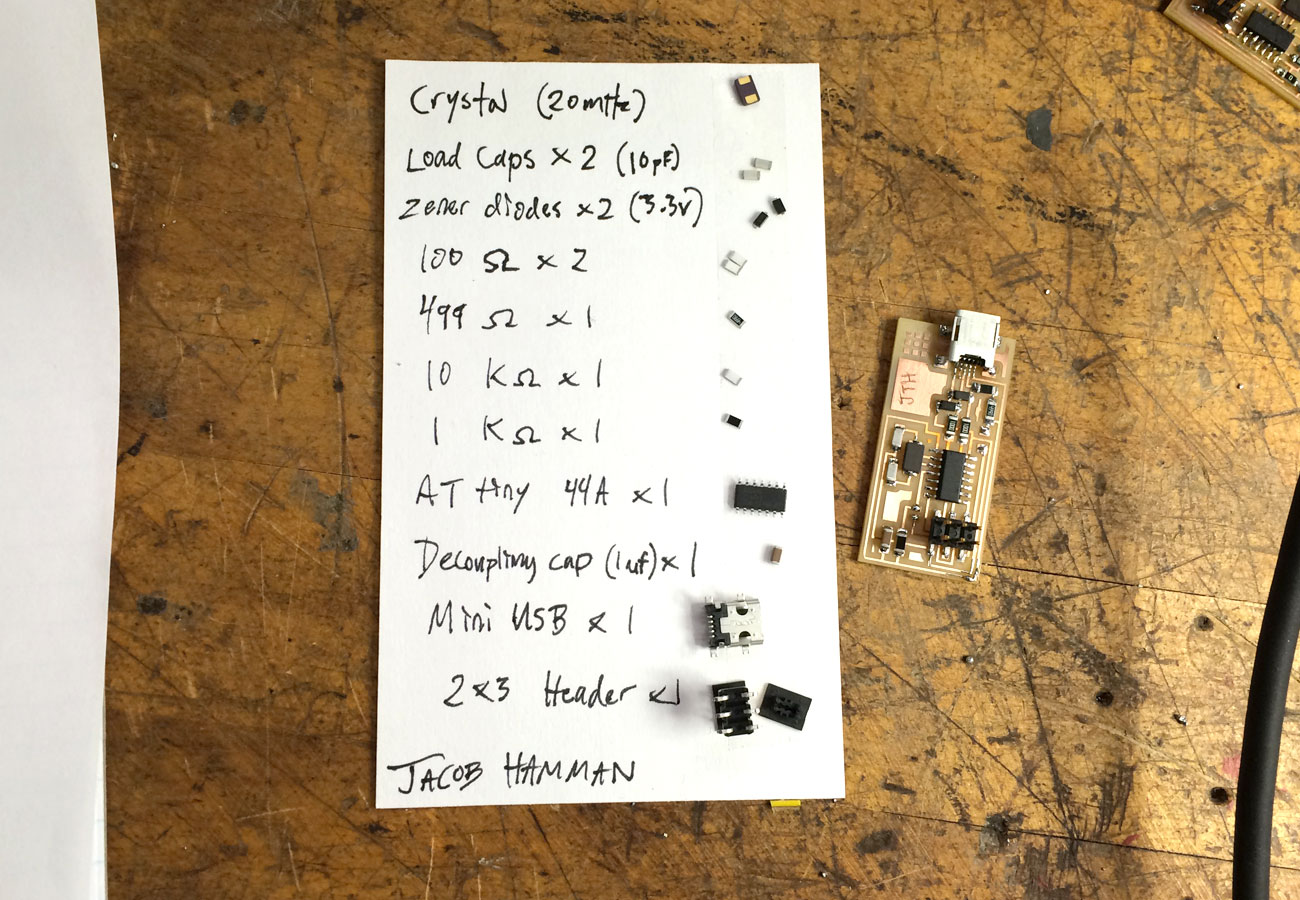

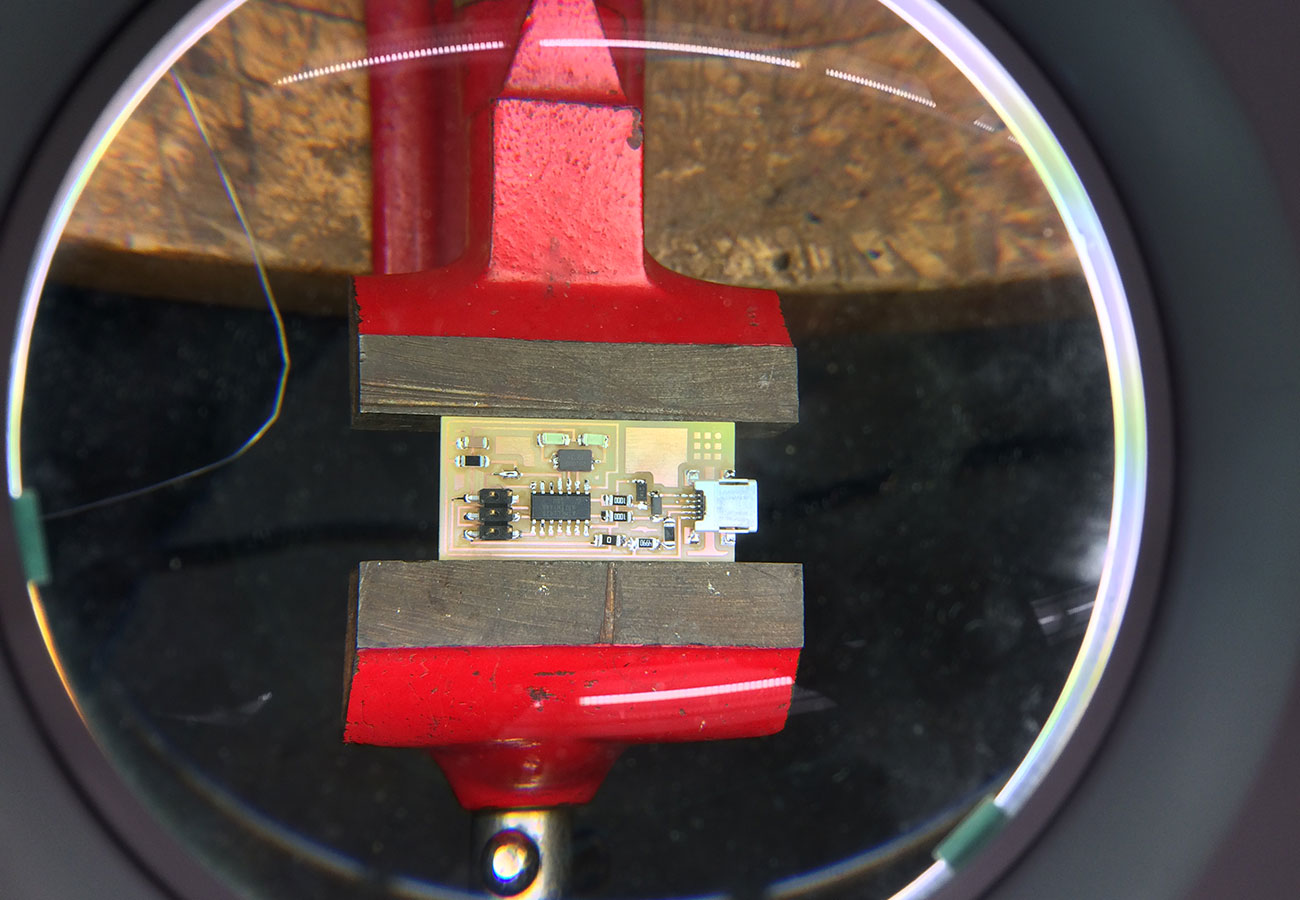

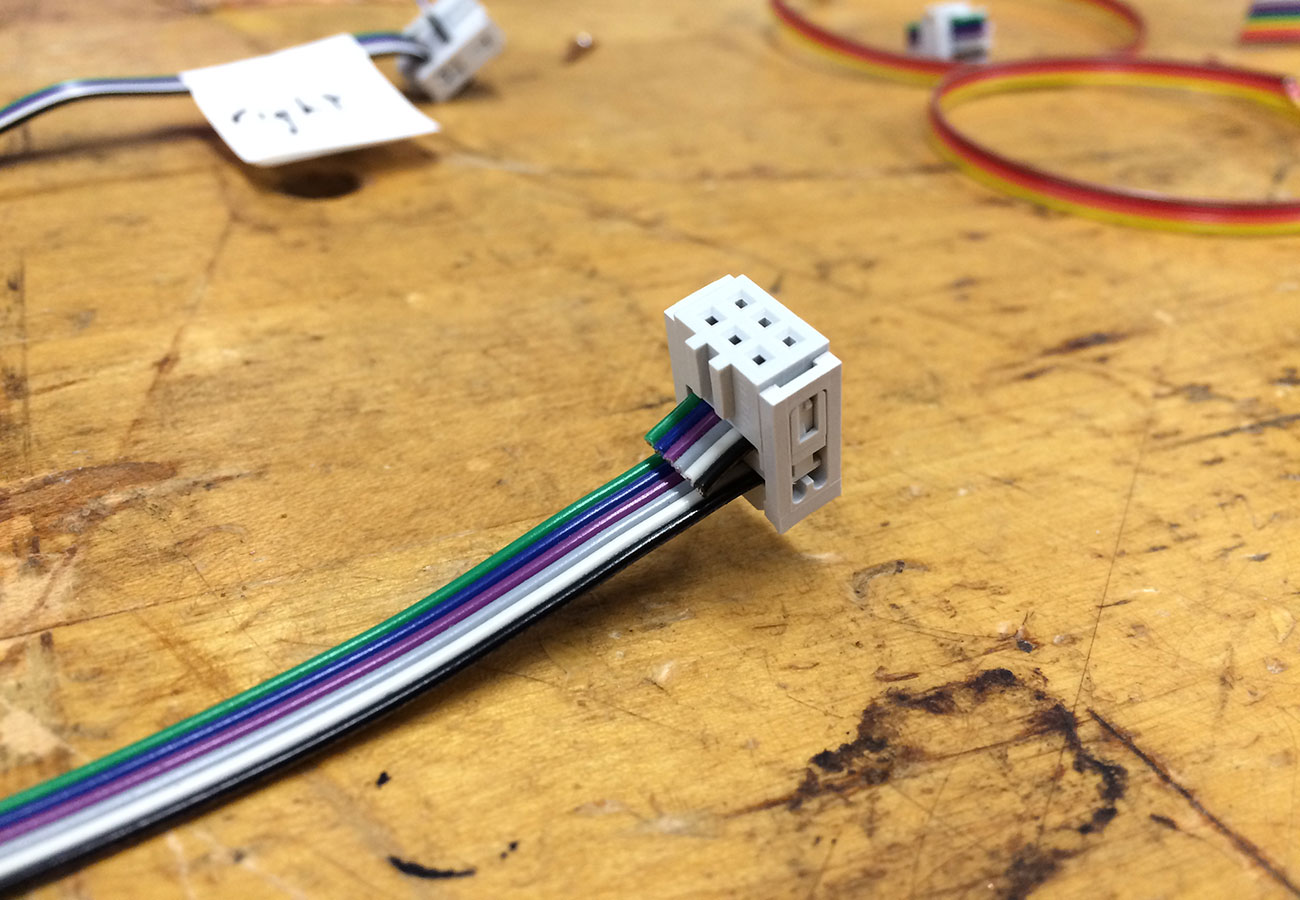

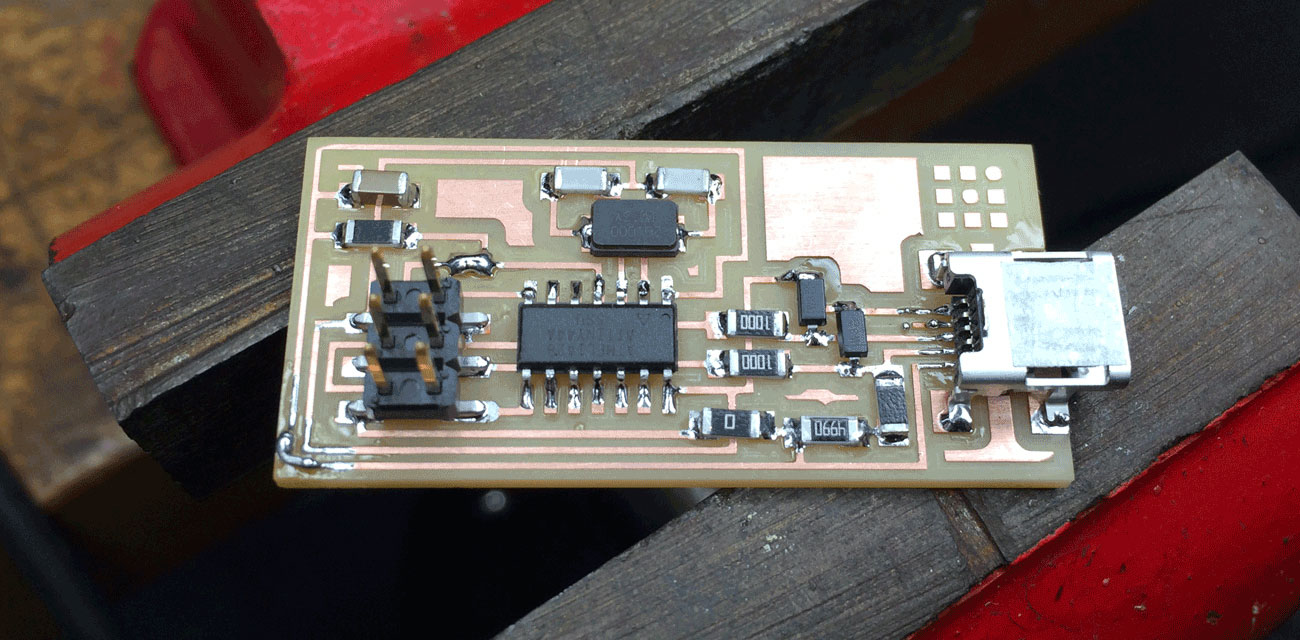

This week's assignment was to create the FabISP, in-circuit programmer. This excercise helped introduce the Roland Desktop Mill, the FabModules, surface-mount soldering, using a multimeter, and basic electronics. The steps to this process involved:

After completing this assignment, I have discovered that I actually enjoy the surgical nature of soldering tiny surface mounted components. I learned about the sensitivity of tightening the end mill set screws, and how much sanding should be necessary to clean the surface of the board. The delicate movements involved with removing solder with the copper braid and placing tiny resistors are difficult to describe and are things that can only be learned through practice. I am still somewhat unsure about what role the FabISP plays in the production of custom circuit boards, but it feels good to have created one.